When selecting a compressor for a plasma cutter, it is important to consider the type of plasma cutter you are using, the size of the tank, the CFM (cubic feet per minute) rating, and the PSI (pounds per square inch) rating.

The type of plasma cutter you are using will determine the type of compressor you need. For example, if you are using a high-frequency plasma cutter, you will need a compressor with a higher CFM rating than if you were using a low-frequency plasma cutter.

The size of the tank is also important. If you are using a large plasma cutter, you will need a larger tank to ensure that the compressor can keep up with the demand.

The CFM rating is the amount of air that the compressor can deliver in a given amount of time. The higher the CFM rating, the more air the compressor can deliver. The CFM rating should be at least 4 CFM for a plasma cutter.

The PSI rating is the amount of pressure the compressor can deliver.

What type of compressor is needed for plasma cutter?

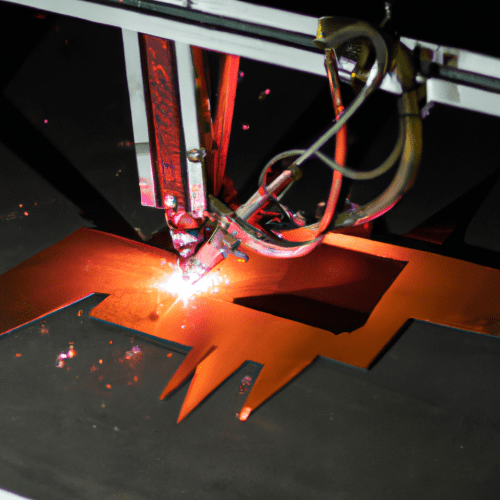

A plasma cutter is a tool used to cut through electrically conductive materials such as steel, aluminum, brass, and copper. It works by using an electrical arc to heat and melt the material, which is then blown away by a high-velocity stream of gas. In order to generate the high-velocity stream of gas, a compressor is needed. The type of compressor needed for a plasma cutter depends on the size and power of the cutter. For smaller, lower-powered cutters, a small, single-stage compressor is usually sufficient. These compressors are typically oil-less and are relatively inexpensive. For larger, higher-powered cutters, a two-stage compressor is usually recommended. These compressors are more expensive, but they are more efficient and provide a higher-pressure output. Additionally, two-stage compressors are typically oil-lubricated, which helps to reduce wear and tear on the compressor.

What size air compressor does it take to run a plasma cutter?

The size of air compressor needed to run a plasma cutter depends on the type of plasma cutter you are using. Generally, plasma cutters require a compressor with a minimum of 3-4 CFM (Cubic Feet per Minute) at 90 PSI (Pounds per Square Inch). However, some plasma cutters require more CFM and PSI than others, so it is important to check the manufacturer’s specifications for the specific model you are using. Additionally, the size of the air compressor you need will also depend on the type of work you are doing. If you are using the plasma cutter for light-duty work, such as cutting thin sheet metal, then a smaller compressor with a lower CFM and PSI rating may be sufficient. However, if you are using the plasma cutter for heavier-duty work, such as cutting thicker metal, then you will need a larger compressor with a higher CFM and PSI rating.

Do you need an air compressor to run a plasma cutter?

No, you do not need an air compressor to run a plasma cutter. Plasma cutters are powered by electricity, and use a combination of gas and electricity to create a high-temperature arc that is used to cut through metal. The gas used in a plasma cutter is usually either compressed air or nitrogen, and the gas is supplied to the cutter through a hose. The gas is then mixed with the electricity to create the arc, and the arc is used to cut through the metal. The air compressor is not necessary for the plasma cutter to work, as the gas can be supplied to the cutter through a hose without the need for an air compressor.

How many amps does it take to run a plasma cutter?

The amount of amps it takes to run a plasma cutter depends on the type of plasma cutter and the type of material being cut. Generally, plasma cutters require between 15 and 40 amps of power to operate. The amount of amps needed to run a plasma cutter also depends on the thickness of the material being cut. Thicker materials require more amps to cut than thinner materials. For example, a plasma cutter with a 40 amp rating may be able to cut up to 1/4 inch thick steel, but may not be able to cut thicker materials. Additionally, the type of plasma cutter also affects the amount of amps needed to run it. Inverter-based plasma cutters require less amps than traditional transformer-based plasma cutters. Inverter-based plasma cutters typically require between 15 and 30 amps, while transformer-based plasma cutters require between 30 and 40 amps.

In conclusion, the amount of amps it takes to run a plasma cutter depends on the type of plasma cutter, the type of material being cut, and the thickness of the material.

How much PSI does a plasma cutter need?

A plasma cutter is a tool used to cut through electrically conductive materials such as steel, aluminum, brass, and copper. The amount of pressure (measured in pounds per square inch, or PSI) needed to operate a plasma cutter depends on the type of plasma cutter being used. Generally, a plasma cutter needs between 40 and 60 PSI of air pressure to operate. However, some plasma cutters require up to 90 PSI of air pressure. Additionally, the type of material being cut can also affect the amount of pressure needed. For example, thicker materials may require more pressure than thinner materials.

It is important to note that the air pressure needed to operate a plasma cutter is not the same as the pressure of the plasma arc itself. The plasma arc is created by a high-voltage electrical current that passes through a gas, such as air or nitrogen, to create a plasma arc. The pressure of the plasma arc is measured in amperes (amps) and is typically between 20 and 40 amps.

What is SCFM vs CFM?

SCFM (Standard Cubic Feet per Minute) and CFM (Cubic Feet per Minute) are both units of measurement used to measure the volumetric flow rate of a gas or air. The main difference between SCFM and CFM is that SCFM is a measure of volumetric flow rate at a specific temperature and pressure, while CFM is a measure of volumetric flow rate at a given pressure, regardless of temperature.

SCFM is used to measure the volumetric flow rate of a gas or air at a specific temperature and pressure. This is important because the volumetric flow rate of a gas or air can vary significantly depending on the temperature and pressure of the environment. For example, the volumetric flow rate of a gas or air at sea level is different than the volumetric flow rate of the same gas or air at a higher altitude. Therefore, SCFM is used to measure the volumetric flow rate of a gas or air at a specific temperature and pressure.

What is needed to run a plasma cutter?

In order to run a plasma cutter, you will need a few key components. First, you will need a power source, such as a generator or a wall outlet. You will also need a plasma cutter, which is a device that uses a high-velocity stream of ionized gas to cut through metal. You will also need a compressed air source, such as an air compressor, to provide the air pressure needed to power the plasma cutter. Additionally, you will need a grounding clamp, which is used to ground the metal being cut and prevent arcing. Finally, you will need a set of safety gear, such as safety glasses, gloves, and a welding helmet, to protect yourself from the sparks and heat generated by the plasma cutter. With these components, you will be able to safely and effectively use a plasma cutter.

Why must a filter dryer be used on the air supply to a plasma torch?

A filter dryer must be used on the air supply to a plasma torch in order to ensure that the air is free of contaminants that could potentially damage the torch or interfere with the cutting process. Contaminants such as water vapor, oil, dirt, and other particles can cause the torch to malfunction or produce an uneven cut. The filter dryer removes these contaminants from the air supply, allowing the torch to operate at peak efficiency. Additionally, the filter dryer helps to regulate the air pressure, ensuring that the torch is supplied with the correct amount of air for optimal performance. Without a filter dryer, the air supply to the torch could be contaminated, leading to poor performance and potentially damaging the torch.