When it comes to choosing the right cutter for a job, there are a few factors to consider. First, you need to think about the material you are cutting. Different materials require different types of cutters. For example, if you are cutting wood, you may want to use a saw or a router. If you are cutting metal, you may want to use a drill bit or a plasma cutter. Second, you need to consider the size and shape of the material you are cutting. If you are cutting a large piece of material, you may need a larger cutter. If you are cutting a small piece of material, you may need a smaller cutter. Third, you need to consider the type of cut you are trying to achieve. Different cutters can produce different types of cuts, such as straight cuts, curved cuts, or angled cuts. Finally, you need to consider the speed and accuracy of the cut. Different cutters can produce different speeds and accuracy levels.

Once you have considered all of these factors, you can then decide which cutter is best for the job. It is important to remember that the right cutter for the job will depend on the material, size, shape, type of cut, and speed and accuracy of the cut.

What is the job of a cutter?

A cutter is a professional who is responsible for cutting and trimming fabric, leather, and other materials to create garments and other products. They use a variety of tools, such as scissors, shears, and electric cutting machines, to cut the material to the desired shape and size. They must be able to accurately measure and cut the material to the exact specifications of the designer or pattern. They must also be able to identify and select the appropriate fabric for the project. In addition to cutting the material, cutters may also be responsible for marking the fabric with chalk or other marking tools, as well as pressing the fabric to ensure a smooth finish. Cutters must also be able to identify and select the appropriate thread and other materials for the project. They must also be able to identify and select the appropriate interfacing and other materials for the project. Finally, cutters must be able to inspect the finished product to ensure that it meets the designer’s specifications.

What is a material cutter?

A material cutter is a tool used to cut through materials such as wood, metal, plastic, and other materials. It is used in a variety of industries, including construction, manufacturing, and engineering. Material cutters come in a variety of shapes and sizes, and can be powered by electricity, air, or manual force. The most common type of material cutter is the circular saw, which is used to cut through wood and other materials. Other types of material cutters include band saws, jigsaws, reciprocating saws, and miter saws. Each type of material cutter is designed to cut through different materials, and each type of material requires a different type of cutter. For example, a band saw is used to cut through metal, while a jigsaw is used to cut through wood. Material cutters are also used to create intricate shapes and patterns in materials, such as inlays and carvings.

What does a metal cutter do?

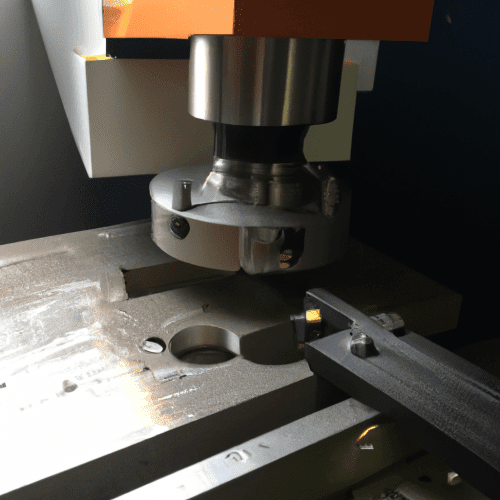

A metal cutter is a type of machine that is used to cut metal into various shapes and sizes. It is typically used in industrial settings, such as factories and workshops, to cut metal into the desired shape for a specific purpose. Metal cutters come in a variety of shapes and sizes, and can be powered by electricity, hydraulics, or pneumatics. The most common type of metal cutter is the shear, which uses two blades to cut metal into a desired shape. Other types of metal cutters include saws, drills, and milling machines.

Metal cutters are used to cut metal into a variety of shapes and sizes, such as circles, squares, rectangles, and triangles. They can also be used to cut metal into more complex shapes, such as curves and angles. Metal cutters are used to cut metal into thin sheets, rods, and tubes, as well as to cut metal into intricate shapes for decorative purposes. Metal cutters are also used to cut metal into pieces for welding, riveting, and other metalworking processes.

What is a cutter in the clothing industry?

A cutter in the clothing industry is a skilled professional who is responsible for cutting and preparing fabric for use in the production of garments. The cutter is responsible for ensuring that the fabric is cut accurately and efficiently, and that the pieces are ready for the next step in the production process. The cutter must be knowledgeable about the different types of fabrics and the different types of cutting techniques that are used in the industry. They must also be able to read and interpret patterns, and be able to make adjustments to the pattern as needed. The cutter must also be able to identify any flaws in the fabric and make the necessary corrections. In addition, the cutter must be able to work with a variety of tools, such as scissors, shears, and cutting machines. The cutter must also be able to work with a variety of fabrics, such as cotton, wool, silk, and synthetic fabrics. The cutter must also be able to work with a variety of colors and textures, and be able to identify any flaws in the fabric and make the necessary corrections.

What is a cutter in the fashion industry?

A cutter in the fashion industry is a professional who is responsible for cutting and assembling fabric pieces to create garments. They are responsible for creating patterns and cutting the fabric according to the pattern. They must be knowledgeable in the use of various tools and machines, such as scissors, shears, and cutting machines. They must also be able to read and interpret patterns and understand the properties of different fabrics.

Cutters must be able to visualize the finished product and have a good eye for detail. They must be able to make precise cuts and be able to adjust the pattern to fit the fabric. They must also be able to identify and correct any errors in the pattern or fabric.

Cutters must also be able to work with a variety of fabrics, including leather, fur, and synthetic materials. They must be able to identify the best way to cut the fabric to create the desired effect. They must also be able to identify any flaws in the fabric and make adjustments to the pattern accordingly.