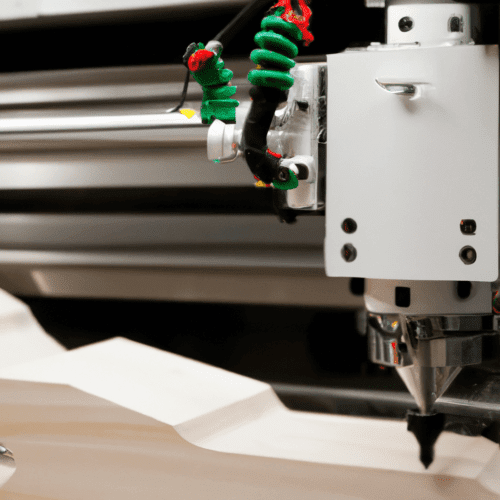

Yes, a CNC mill can cut wood. CNC mills are computer-controlled machines that are used to cut and shape materials such as wood, metal, and plastic. They are used in a variety of industries, including woodworking, metalworking, and manufacturing. CNC mills are capable of cutting a wide variety of materials, including wood.

When cutting wood with a CNC mill, the type of wood and the desired shape will determine the type of tool that is used. For example, a router bit is typically used for cutting out shapes in wood, while an end mill is used for cutting out slots and holes. The type of wood being cut will also determine the speed and feed rate of the CNC mill. Harder woods, such as oak, require slower speeds and higher feed rates, while softer woods, such as pine, require faster speeds and lower feed rates.

The CNC mill can also be used to cut intricate shapes and patterns in wood. This is done by programming the CNC mill to follow a specific path. The CNC mill can be programmed to cut out shapes such as circles, squares, and triangles, as well as more complex shapes such as spirals and curves.

In addition to cutting wood, CNC mills can also be used to engrave wood. This is done by using a special engraving bit that is designed to cut into the wood. The engraving bit is programmed to follow a specific path, and the CNC mill will then cut out the desired pattern.

Overall, CNC mills are a versatile tool that can be used to cut and shape a variety of materials, including wood. With the right tools and programming, a CNC mill can be used to cut out intricate shapes and patterns in wood, as well as engrave wood.

How thick of wood can a CNC machine cut?

A CNC machine can cut wood of any thickness, depending on the type of CNC machine and the type of wood being cut. Generally, CNC machines are capable of cutting wood up to 3 inches thick, but some machines can cut up to 6 inches thick. The type of wood being cut also affects the thickness that can be cut. Hardwoods, such as oak, maple, and walnut, are more difficult to cut than softwoods, such as pine and cedar. The type of bit used in the CNC machine also affects the thickness of wood that can be cut. For example, a router bit is designed to cut softer woods, while a saw blade is designed to cut harder woods. Additionally, the speed of the CNC machine and the feed rate of the material being cut also affect the thickness of wood that can be cut. The faster the speed and the higher the feed rate, the thicker the wood that can be cut.

In conclusion, the thickness of wood that can be cut by a CNC machine depends on the type of CNC machine, the type of wood being cut, the type of bit used, and the speed and feed rate of the machine. Generally, CNC machines are capable of cutting wood up to 3 inches thick, but some machines can cut up to 6 inches thick.

Can you cut with a CNC?

Yes, you can cut with a CNC (Computer Numerical Control) machine. CNC machines are automated tools that are programmed to cut and shape materials with precision and accuracy. They are used in a variety of industries, including woodworking, metalworking, and plastics manufacturing. CNC machines are capable of cutting a wide range of materials, including wood, metal, plastic, foam, and composites.

CNC machines are programmed with a computer-aided design (CAD) software, which allows the user to create a 3D model of the desired shape or design. The CNC machine then reads the CAD file and uses its cutting tools to cut the material according to the programmed instructions. The cutting tools used in CNC machines can range from a router bit to a laser cutter, depending on the material being cut.

CNC machines are highly accurate and can produce complex shapes with precision. They are also capable of cutting intricate details, such as grooves, slots, and holes. CNC machines are also able to cut multiple pieces of material at once, which can save time and money.

CNC machines are used in a variety of industries, including aerospace, automotive, medical, and electronics. They are also used in the production of furniture, musical instruments, and toys. CNC machines are also used in the production of signs, displays, and other products.

CNC machines are a great tool for cutting materials with precision and accuracy. They are capable of cutting a wide range of materials and can produce complex shapes with intricate details. CNC machines are used in a variety of industries and can save time and money by cutting multiple pieces of material at once.

Can you cut wood on a milling machine?

Milling machines are a type of machine tool used to shape and cut materials such as wood, metal, and plastic. While milling machines are typically used to shape metal, they can also be used to shape wood. However, it is important to note that milling machines are not designed specifically for cutting wood, and so the process of cutting wood on a milling machine is not as efficient as it would be with a saw or other woodworking tool.

When cutting wood on a milling machine, it is important to use the correct cutting tools and techniques. The most common cutting tool used for cutting wood on a milling machine is a router bit. Router bits are designed to cut wood quickly and accurately, and they come in a variety of shapes and sizes to suit different types of woodworking projects. It is important to select the correct router bit for the job, as using the wrong bit can cause damage to the wood or the machine.

When cutting wood on a milling machine, it is important to use the correct cutting speed and feed rate. The cutting speed should be set to the lowest speed that will still produce a clean cut, and the feed rate should be set to the highest speed that will still produce a clean cut. It is also important to use a lubricant, such as cutting oil, to reduce friction and heat buildup while cutting.

Finally, it is important to use the correct safety equipment when cutting wood on a milling machine. This includes safety glasses, hearing protection, and a dust mask. It is also important to ensure that the machine is properly secured to the workbench, and that all moving parts are properly lubricated. Following these safety precautions will help to ensure that the cutting process is safe and efficient.

How thin can you CNC?

CNC stands for Computer Numerical Control, and it is a process used to cut and shape materials with precision. The thinness of the material that can be cut with CNC depends on the type of CNC machine being used. Generally, CNC machines are capable of cutting materials as thin as 0.001 inches, although some machines are capable of cutting materials as thin as 0.0001 inches. The type of material being cut also affects the thinness that can be achieved. For example, softer materials such as wood and plastic can be cut more precisely than harder materials such as steel and aluminum.

The type of tool being used also affects the thinness that can be achieved. For example, end mills are typically used to cut softer materials, while drills are used to cut harder materials. The size of the tool also affects the thinness that can be achieved. Smaller tools are capable of cutting thinner materials than larger tools.

The speed of the CNC machine also affects the thinness that can be achieved. Slower speeds are typically used to cut thinner materials, while faster speeds are used to cut thicker materials. The accuracy of the CNC machine also affects the thinness that can be achieved. Higher accuracy machines are capable of cutting thinner materials than lower accuracy machines.

In conclusion, the thinness that can be achieved with CNC depends on the type of CNC machine, the type of material being cut, the type of tool being used, the size of the tool, the speed of the CNC machine, and the accuracy of the CNC machine. Generally, CNC machines are capable of cutting materials as thin as 0.001 inches, although some machines are capable of cutting materials as thin as 0.0001 inches.

Can a CNC router cut hardwood?

Yes, a CNC router can cut hardwood. CNC routers are computer-controlled machines that are used to cut and shape a variety of materials, including hardwood. CNC routers are equipped with a variety of cutting tools, such as end mills, drill bits, and router bits, which can be used to cut hardwood. The cutting tools are usually made of high-speed steel or carbide, which are both strong enough to cut hardwood. The cutting speed and depth of the cut can be adjusted depending on the type of hardwood being cut. The cutting speed should be adjusted to a slower speed when cutting hardwood, as hardwood is more dense and requires more time to cut. The depth of the cut should also be adjusted to a shallower depth when cutting hardwood, as hardwood is more prone to splintering and chipping. Additionally, the cutting tools should be sharpened regularly to ensure a clean cut. CNC routers can also be used to engrave hardwood, which is a great way to add detail and texture to a project. With the right settings and cutting tools, a CNC router can be used to cut and engrave hardwood with precision and accuracy.

What is CNC?

CNC stands for Computer Numerical Control, and it is a type of automation technology used in the manufacturing industry. It is a process that uses computer-controlled machines to perform a variety of tasks, such as cutting, drilling, and milling. CNC machines are programmed with a set of instructions that tell the machine what to do and how to do it. The instructions are written in a computer language called G-code, which is a set of commands that tell the machine what to do and how to do it. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC machines are highly accurate and can produce parts with a high degree of precision. They are also able to produce parts quickly and efficiently, which makes them ideal for mass production. CNC machines are also relatively easy to use and maintain, which makes them a popular choice for many manufacturers.

CNC machines are used in a variety of ways, from creating prototypes to producing finished products. They can be used to create complex shapes and patterns, as well as to cut and shape materials. CNC machines are also used to create molds and dies for injection molding and die casting. CNC machines are also used to create custom parts for a variety of applications, such as medical devices, automotive parts, and consumer products.

CNC machines are an important part of the manufacturing process, and they are used in a variety of industries. They are highly accurate, efficient, and easy to use, making them a popular choice for many manufacturers.

What can a CNC mill cut?

A CNC mill is a type of machining tool that is computer-controlled and can be used to cut a variety of materials. It is typically used to create parts with complex shapes and features, such as those found in the aerospace, automotive, and medical industries. CNC mills can cut a wide range of materials, including metals, plastics, composites, and wood.

When cutting metals, CNC mills can be used to create parts with intricate shapes and features. They can cut through a variety of metals, including aluminum, steel, stainless steel, brass, and titanium. CNC mills can also be used to cut through plastics, such as acrylic, polycarbonate, and nylon. They can also be used to cut through composites, such as carbon fiber and fiberglass.

CNC mills can also be used to cut through wood. They can be used to create parts with complex shapes and features, such as furniture, cabinets, and other woodworking projects. CNC mills can also be used to cut through foam, rubber, and other soft materials.

CNC mills are versatile tools that can be used to create a variety of parts with complex shapes and features. They can be used to cut through a variety of materials, including metals, plastics, composites, wood, foam, and rubber.

Can CNC machine cut plywood?

Yes, CNC machines can cut plywood. CNC stands for Computer Numerical Control, and it is a type of automated machining process that uses computer-controlled tools to cut and shape materials. Plywood is a type of engineered wood product made from thin layers of wood veneer that are glued together. It is a popular material for furniture, cabinetry, and other woodworking projects.

CNC machines are capable of cutting plywood with precision and accuracy. The machine is programmed with a computer-aided design (CAD) program, which allows the operator to input the desired shape and size of the cut. The machine then uses a cutting tool, such as a router, to cut the plywood according to the programmed specifications. The cutting tool is guided by a computer-controlled system, which ensures that the cuts are precise and accurate.

CNC machines can be used to cut plywood into a variety of shapes and sizes, including circles, squares, rectangles, and other complex shapes. The machine can also be used to cut intricate patterns and designs into the plywood. The cutting speed and accuracy of the CNC machine make it an ideal tool for cutting plywood for furniture, cabinetry, and other woodworking projects.

How deep can a CNC mill cut?

A CNC mill is a type of machining tool that is used to shape and cut materials such as metal, wood, and plastic. The depth of cut that a CNC mill can achieve depends on a variety of factors, including the type of material being cut, the size of the mill, and the type of cutting tool being used. Generally speaking, a CNC mill can cut up to several inches deep, depending on the material and the size of the mill. For example, a small CNC mill with a 1/4 inch end mill can cut up to 1/2 inch deep into aluminum, while a larger CNC mill with a 1/2 inch end mill can cut up to 1 inch deep into aluminum. The depth of cut can also be increased by using a larger end mill or by using a cutting tool with a higher cutting speed. Additionally, the depth of cut can be increased by using a cutting fluid, which helps to reduce friction and heat buildup during the cutting process. Ultimately, the depth of cut that a CNC mill can achieve is determined by the size of the mill, the type of cutting tool being used, and the material being cut.

Can a metal milling machine be used for wood?

Yes, a metal milling machine can be used for wood. Milling machines are versatile tools that can be used to shape and cut a variety of materials, including wood. While metal milling machines are typically used for metalworking, they can also be used to shape and cut wood. The key to successful wood milling with a metal milling machine is to use the correct cutting tools and to adjust the machine’s speed and feed rate to the material being cut.

When using a metal milling machine for wood, it is important to select the correct cutting tools. High-speed steel (HSS) cutters are the most common type of cutting tool used for wood milling. HSS cutters are designed to cut wood quickly and efficiently, and they are available in a variety of shapes and sizes. It is also important to select the correct cutting speed and feed rate for the material being cut. The cutting speed should be adjusted to the hardness of the wood, while the feed rate should be adjusted to the size of the material being cut.

In addition to selecting the correct cutting tools and adjusting the machine’s speed and feed rate, it is also important to use the correct lubricant when milling wood with a metal milling machine. A lubricant helps to reduce friction and heat, which can cause the wood to burn or melt. A light oil or wax is typically used as a lubricant when milling wood with a metal milling machine.

Overall, a metal milling machine can be used for wood, but it is important to select the correct cutting tools, adjust the machine’s speed and feed rate, and use the correct lubricant. With the right tools and techniques, a metal milling machine can be used to shape and cut wood with precision and accuracy.

What wood is best for machining?

When it comes to machining wood, there is no single “best” wood. The type of wood that is best for machining depends on the specific project and the desired outcome. Generally, hardwoods are better for machining than softwoods, as they are more dense and less likely to splinter or chip. Hardwoods such as maple, oak, and walnut are popular choices for machining, as they are strong and durable. Softwoods such as pine and cedar are also suitable for machining, but they are more prone to splintering and chipping.

When selecting a wood for machining, it is important to consider the grain of the wood. Woods with a straight grain are easier to machine than woods with a cross grain, as the grain of the wood affects the cutting action of the tools. Woods with a straight grain are also less likely to splinter or chip. Additionally, the hardness of the wood should be taken into consideration. Harder woods are more difficult to machine, but they are also more durable and less likely to splinter or chip.

Finally, the type of finish desired should be taken into consideration when selecting a wood for machining. Some woods are better suited for a natural finish, while others are better suited for a painted or stained finish. For example, maple is a popular choice for machining because it is strong and durable, and it is also well-suited for a painted or stained finish.

In conclusion, there is no single “best” wood for machining. The type of wood that is best for machining depends on the specific project and the desired outcome. Hardwoods such as maple, oak, and walnut are popular choices for machining, as they are strong and durable. Softwoods such as pine and cedar are also suitable for machining, but they are more prone to splintering and chipping. Additionally, the grain of the wood and the desired finish should be taken into consideration when selecting a wood for machining.

Is Oak good for CNC carving?

CNC carving is a process of cutting and shaping materials using a computer-controlled router or milling machine. Oak is a popular choice for CNC carving due to its strength, durability, and attractive grain pattern. Oak is a hardwood, which makes it ideal for carving intricate designs and shapes. It is also relatively easy to work with, making it a great choice for beginners. Oak is also resistant to splitting and cracking, which makes it a great choice for projects that require precision and accuracy. Additionally, oak is relatively inexpensive compared to other hardwoods, making it a great choice for those on a budget.

When it comes to CNC carving, oak is a great choice due to its strength, durability, attractive grain pattern, and affordability. It is easy to work with and resistant to splitting and cracking, making it a great choice for projects that require precision and accuracy. Additionally, oak is relatively inexpensive compared to other hardwoods, making it a great choice for those on a budget.

Is MDF good for CNC carving?

MDF (medium-density fiberboard) is a popular material for CNC carving due to its affordability, availability, and ease of use. It is a composite material made from wood fibers and resin, and is available in a variety of thicknesses and sizes. MDF is a great material for CNC carving because it is relatively soft and easy to work with, and it can be cut into intricate shapes with a CNC machine. It is also relatively inexpensive compared to other materials, making it a great choice for projects that require a lot of material.

MDF is not without its drawbacks, however. It is not as strong as other materials, and it is prone to chipping and splintering when cut. It is also not as durable as other materials, and it can be prone to warping if not properly sealed. Additionally, MDF is not suitable for outdoor use, as it is not waterproof and can be damaged by moisture.

Overall, MDF is a great material for CNC carving, as it is relatively inexpensive, easy to work with, and can be cut into intricate shapes. However, it is important to consider the drawbacks of MDF before using it for a project, as it is not as strong or durable as other materials and is not suitable for outdoor use.

What are common home products that have been made using CNC machines?

CNC (Computer Numerical Control) machines are used to create a variety of products, from small items like jewelry and toys to large items like furniture and appliances. Common home products that have been made using CNC machines include kitchen cabinets, countertops, doors, windows, furniture, and even toys. CNC machines are also used to create custom items such as signs, plaques, and sculptures. CNC machines are used to create intricate designs and shapes that would be difficult to achieve with traditional methods. CNC machines are also used to create parts for appliances, such as washing machines, refrigerators, and dishwashers. CNC machines are also used to create parts for cars, motorcycles, and other vehicles. CNC machines are used to create parts for medical equipment, such as prosthetics and implants. CNC machines are also used to create parts for electronics, such as computers, phones, and tablets. CNC machines are used to create parts for industrial equipment, such as pumps, valves, and turbines. CNC machines are also used to create parts for aerospace and defense applications, such as aircraft and missiles. CNC machines are used to create parts for a variety of other products, such as musical instruments, sporting goods, and toys.

Can you use a CNC machine for wood and metal?

Yes, you can use a CNC machine for both wood and metal. CNC stands for Computer Numerical Control, and it is a type of automated machining process that uses computer-controlled commands to cut and shape materials. CNC machines are used in a variety of industries, including woodworking, metalworking, and plastics manufacturing.

CNC machines are capable of cutting and shaping both wood and metal materials. For woodworking, CNC machines are used to create intricate designs and shapes, such as furniture, cabinetry, and musical instruments. For metalworking, CNC machines are used to create parts for cars, airplanes, and other machinery.

CNC machines are highly precise and can be programmed to cut and shape materials with great accuracy. They are also capable of producing complex shapes and designs that would be difficult or impossible to achieve with traditional machining methods.

CNC machines are also relatively easy to use and require minimal setup time. They can be programmed to cut and shape materials with a variety of tools, such as routers, drills, and saws. This makes them ideal for both large-scale and small-scale projects.

Overall, CNC machines are a great tool for both woodworking and metalworking. They are highly precise, easy to use, and capable of producing complex shapes and designs.

Is CNC milling hard?

CNC milling can be a difficult process to master, but it is not necessarily hard. CNC milling is a process that involves the use of computer numerical control (CNC) machines to cut and shape materials into desired shapes and sizes. The process requires a great deal of precision and accuracy, as the machines must be programmed to cut the material in a specific way. This requires a good understanding of the CNC machine and the materials being cut.

The difficulty of CNC milling depends on the complexity of the project. Simple projects may require only basic programming and setup, while more complex projects may require more advanced programming and setup. Additionally, the type of material being cut can also affect the difficulty of the process. Harder materials may require more precise programming and setup, while softer materials may require less precision.

In addition to the programming and setup, the operator must also be familiar with the CNC machine and its safety protocols. This includes understanding the machine’s capabilities and limitations, as well as the proper use of safety equipment.

Overall, CNC milling is not necessarily hard, but it does require a good understanding of the process and the materials being cut. With the right knowledge and experience, CNC milling can be a rewarding and enjoyable experience.

Are CNC routers worth it?

CNC routers are computer-controlled cutting machines used to create shapes and designs from a variety of materials. They are used in a variety of industries, from woodworking to automotive manufacturing. CNC routers are a great investment for businesses that need to produce high-quality, precise parts quickly and efficiently.

The main benefit of CNC routers is their accuracy and repeatability. CNC routers are programmed to cut parts with a high degree of precision, which is essential for many industries. This accuracy and repeatability also allows for faster production times, as the same parts can be cut multiple times without having to be re-measured or re-programmed. Additionally, CNC routers can be programmed to cut a variety of materials, from wood to metal, making them a versatile tool for many businesses.

CNC routers also offer a number of safety benefits. Since the machines are computer-controlled, they can be programmed to stop if something goes wrong, preventing accidents and injuries. Additionally, CNC routers can be programmed to cut parts with a high degree of accuracy, reducing the risk of human error.

The cost of CNC routers can vary depending on the size and complexity of the machine. However, the cost is often offset by the increased efficiency and accuracy that CNC routers provide. Additionally, CNC routers can be used to produce a variety of parts, which can help businesses save money by reducing the need to purchase multiple machines for different tasks.

Overall, CNC routers are a great investment for businesses that need to produce high-quality, precise parts quickly and efficiently. The accuracy and repeatability of CNC routers can help businesses save time and money, while the safety features can help reduce the risk of accidents and injuries.