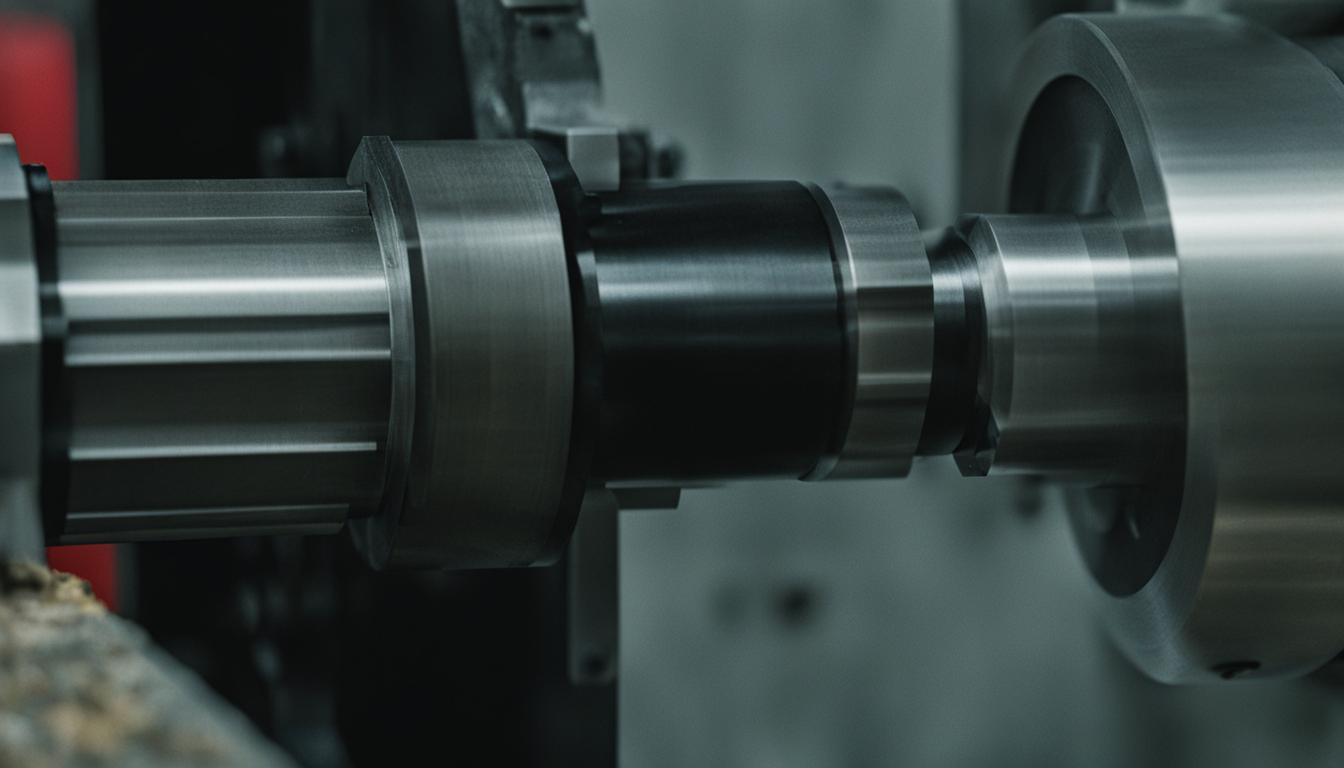

Milling on a lathe is indeed possible, though it comes with limitations and challenges. While not ideal for extensive milling operations, a lathe can be adapted for light milling tasks when a dedicated milling machine is unavailable. This technique involves mounting the workpiece on the lathe’s cross-slide or compound rest and using the spindle to hold an end mill or other cutting tool.

The lathe’s carriage movement can then be utilized to create linear cuts, while the cross-slide provides limited Y-axis motion. However, users should be aware of several constraints: the setup is generally less rigid than a proper milling machine, which can lead to reduced accuracy and potential chatter; the range of motion is restricted, limiting the size and complexity of parts that can be milled; and the spindle speeds may not be optimal for milling operations.

Despite these drawbacks, lathe milling can be a valuable skill for machinists, particularly in small workshops or for one-off projects. It’s essential to take light cuts, maintain proper tool alignment, and ensure all gibs and locks are tightened to maximize stability and precision. While not a substitute for a dedicated milling machine, this technique can expand the capabilities of a lathe and provide a workable solution for simple milling tasks in a pinch.

- Using a mill as a lathe is not practical and can lead to faster tool wear and limitations on the size of the workpiece.

- A lathe can perform milling operations and even create parts to build a mill, making it a more viable option for multi-functionality.

- While milling on a lathe may be feasible in some situations, there are limitations to consider, such as spindle capacity and workpiece length.

- Considerations for milling on a lathe include the need for a vertical slide with a suitable vice or clamps and the size and rigidity of your lathe.

- Specific tools and attachments, such as boring bars and solid carbide cutters, are necessary for successful lathe milling.

Why You Should NOT Use a Mill as a Lathe

Using a mill as a lathe is not practical for several reasons. It requires reversing the normal order of operations, which can lead to faster tool wear and limitations on the size of the workpiece. Additionally, using a lathe as a mill is a more viable option as most lathes can perform milling operations and even create parts to build a mill. If you need a machine that can perform multiple functions, it’s best to invest in a lathe.

Limitations of Milling on a Lathe

When attempting lathe milling techniques, it’s essential to consider the limitations and challenges that arise from using a mill as a lathe.

- Reversing Order of Operations: When utilizing a mill as a lathe, the order of operations needs to be reversed. This change can lead to faster tool wear and compromises on the milling capabilities of the machine.

- Workpiece Size Limitations: Using a mill as a lathe imposes size restrictions on the workpiece. The stationary workpiece design of a mill may limit the length and diameter of the objects that can be worked on.

While it is technically possible to use a mill as a lathe, it is not the most efficient or recommended approach. By utilizing a lathe for milling processes, you can achieve better results and tap into its inherent milling capabilities.

| Lathe Milling Techniques | Lathe Milling Capabilities | Lathe Milling Process |

|---|---|---|

| Precision Cutting with Carbide Tools | Milling Operations | Gentle and Steady Machining |

| Boring Between Centers | Facing | Accurate and Precise Cuts |

| Horizontal Mills for Feasible Applications | Limitations on Spindle Overload | Optimum Length of Workpiece (3-6 inches) |

Why You Could Use a Mill as a Lathe

In certain situations, using a mill as a lathe may be feasible, especially with horizontal mills. While it is not the recommended approach, it can provide a temporary solution in specific circumstances. However, it is important to be aware of the limitations when utilizing a mill for lathe-like operations.

Most mill spindles are primarily designed to hold tools, not workpieces. Therefore, caution must be exercised to avoid overloading the spindle and causing damage to the mill. The length of the workpiece that can be accommodated is also limited, typically ranging from 3 to 6 inches or even shorter.

The tolerances achievable when using a mill as a lathe may not be as precise as those obtained using a dedicated lathe. Typically, the tolerances range within 0.005” – 0.010” for mill-turned workpieces.

Considerations for Milling on a Lathe:

1. Ensure the mill spindle is capable of safely accommodating the workpiece.

2. Limit the length of the workpiece to prevent strain on the mill’s spindle and maintain stability.

3. Keep in mind that tolerances may be slightly less precise compared to traditional lathe operations.

| Advantages | Disadvantages |

|---|---|

| Can be a temporary solution in specific cases where a lathe is not available | Limitations on workpiece length and achievable tolerances |

| Provides an alternative option for basic lathe-like operations | Potential strain on mill spindle |

| Possible tool wear due to reversed order of operations |

While it is possible to use a mill as a lathe under certain circumstances, it is important to thoroughly evaluate the risks and limitations involved. Investing in a dedicated lathe will always provide superior results and precision for lathe milling operations.

Considerations for Milling on a Lathe

If you’re interested in exploring the possibility of milling on a lathe, there are several important considerations to keep in mind. By understanding these factors, you can ensure that your milling operations on a lathe are successful and yield the desired results.

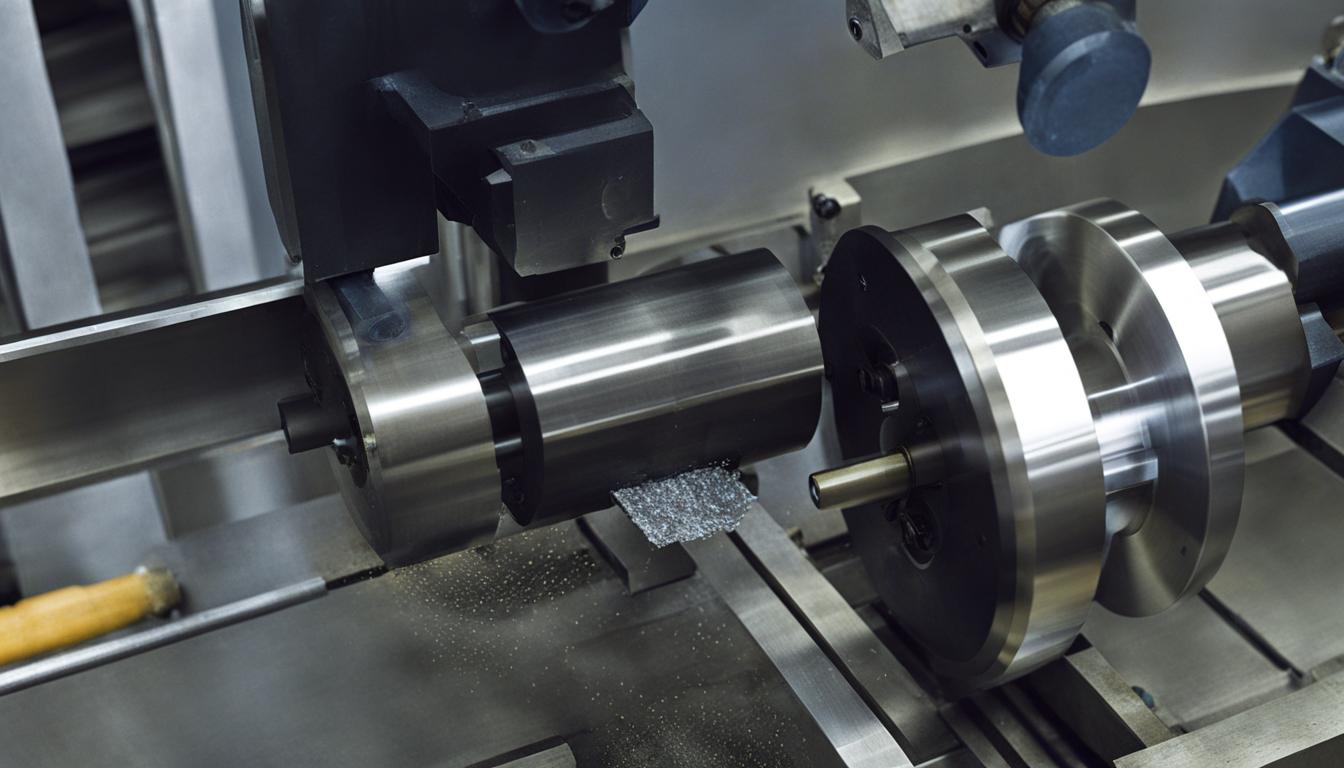

To begin milling on a lathe, you will need a vertical slide equipped with a suitable vice or clamps. This enables you to securely hold the workpiece in place while performing milling operations. The vertical slide provides the necessary stability and precision required for accurate milling.

The size and rigidity of your lathe play a crucial role in determining the limitations of your milling operations. A larger and more robust lathe can accommodate larger workpieces and handle more demanding milling tasks. On the other hand, smaller lathes may have size restrictions and may not be able to handle heavy milling loads.

When performing milling operations on a lathe, it’s essential to take gentle cuts. This approach helps to preserve the integrity of both the lathe and the workpiece, preventing unwanted damage or errors. Additionally, steady machining is crucial to achieving optimal results. Maintaining a consistent and controlled feed rate ensures smooth cutting action and minimizes the risk of accidents or tool breakage.

Two common operations that can be easily performed on a lathe during milling are boring between centers and facing. These operations allow for the creation of accurate holes and flat surfaces on the workpiece, expanding the versatility of your lathe for milling purposes.

By considering these factors and following best practices, you can effectively use a lathe for milling operations. While it may not offer the same level of precision and capabilities as a dedicated milling machine, a lathe can still be a valuable tool for certain milling tasks.

Common Tools and Attachments for Lathe Milling

| Tool | Function |

|---|---|

| Boring Bars | Used for creating accurate holes and enlarging existing holes. |

| Adjustable Reamers | Allow for precise sizing and finishing of holes. |

| Solid Carbide Cutters | Designed for high-speed cutting and shaping of metal. |

Tools and Attachments for Lathe Milling

To perform milling on a lathe, you will need specific tools and attachments. These tools are essential for achieving accurate and precise cuts during milling operations. Here are some of the key tools and attachments used in lathe milling:

Boring Bars

Boring bars play a vital role in lathe milling operations. These tools are used to enlarge existing holes or create new ones with precision. They come in various sizes and shapes, allowing for versatility in different milling applications.

Adjustable Reamers

Adjustable reamers are useful for achieving high levels of accuracy in hole sizing and finishing. These tools can be adjusted to achieve the desired hole diameter and provide a smooth and precise finish.

Solid Carbide Cutters

Solid carbide cutters are known for their durability and precision. These cutters are ideal for cutting different materials, including metals, plastics, and composites. They can withstand high cutting speeds and maintain sharp cutting edges for extended periods.

Vertical Slide with Vice or Clamps

A vertical slide with a vice or clamps is an essential attachment for holding the workpiece securely during milling operations. It provides stability and ensures that the workpiece remains in place throughout the milling process.

When selecting tools and attachments for lathe milling, it’s important to consider the specific requirements of your milling project. Choosing the right tools will help you achieve accurate cuts and ensure the success of your lathe milling operations.

| Tool/Attachment | Function |

|---|---|

| Boring Bars | Enlarge existing holes or create new ones |

| Adjustable Reamers | Ensure precise hole sizing and finishing |

| Solid Carbide Cutters | Provide durability and precision in cutting |

| Vertical Slide with Vice or Clamps | Hold the workpiece securely during milling operations |

The Limitations of Milling on a Lathe

While it is possible to perform milling operations on a lathe, there are limitations to consider. The rigidity and size of your lathe can impact the quality of the milling operations. It’s important to take steady and light cuts to avoid damaging the lathe. Additionally, achieving precise tolerances may be more challenging compared to using a dedicated milling machine.

Milling on a lathe requires careful consideration of the machine’s capabilities and limitations. The primary purpose of a lathe is to rotate a workpiece, allowing for turning, facing, and other operations that shape the workpiece. Milling, on the other hand, involves removing material from the workpiece using a rotating cutter.

When milling on a lathe, the tool is typically mounted on a tool post or a vertical slide attached to the lathe’s cross-slide. This arrangement lacks the rigidity and stability of a dedicated milling machine, which can impact the accuracy and precision of the milling operation. The forces involved in milling can put additional strain on the lathe’s components, potentially leading to deflection and inaccuracies in the finished workpiece.

Another limitation of milling on a lathe is the size of the workpiece that can be accommodated. Lathe chucks are designed to hold cylindrical workpieces, and milling larger, irregularly shaped workpieces can be challenging. The limited space between the chuck and the lathe bed may restrict the size and complexity of the workpiece that can be milled.

To mitigate these limitations, it’s crucial to take light cuts and use appropriate cutting speeds and feeds when milling on a lathe. This helps minimize the strain on the lathe and ensures smoother, more precise cuts. It’s also important to select the right cutting tools and tooling setups that are suitable for lathe milling operations.

In summary, while milling on a lathe is possible, it is important to be mindful of the limitations. The rigidity, size, and accuracy of the lathe can impact the quality of milling operations. If precise tolerances and complex milling tasks are required, investing in a dedicated milling machine would be a better option. However, with careful planning and proper techniques, it is possible to achieve satisfactory results milling on a lathe.

Choosing the Right Machine for Your Needs

When it comes to milling on a lathe, the decision to use a mill as a lathe or invest in separate machines depends on your specific needs. If you require precise milling operations and the ability to perform multiple functions, it is highly recommended to invest in a dedicated lathe and a milling machine separately.

A lathe with milling capabilities offers numerous advantages. It allows for greater precision and accuracy in milling operations, ensuring that your workpieces meet the desired specifications. Additionally, separate machines provide the flexibility to perform various tasks simultaneously, maximizing productivity and efficiency.

However, if you are facing budget or space constraints and only require basic milling operations, using a mill as a lathe may be a practical solution. While there are limitations to consider, such as the size and rigidity of the lathe, it can still be a viable option for achieving satisfactory results in simple milling tasks.

In conclusion, choosing the right machine for your needs boils down to the specific requirements of your projects and the resources available to you. Whether you opt for separate machines or utilize a lathe for milling, it is crucial to consider factors such as milling capabilities, the tools required, and the level of precision needed to ensure successful and efficient machining operations.