CNC conversion kits are specialized packages designed to transform manual machines into computer-controlled systems, enhancing precision, efficiency, and automation capabilities. These kits typically include essential components such as stepper motors, motor drivers, a control board, and necessary software to integrate digital control into existing machinery. By retrofitting manual lathes, mills, routers, or other tools with CNC technology, users can achieve higher accuracy, repeatability, and complex operations that were previously challenging or impossible.

The conversion process involves replacing manual controls with motorized axes, installing sensors for position feedback, and implementing a computer interface for programming and operation. This upgrade allows for the execution of intricate designs, consistent production runs, and reduced human error. CNC conversion kits cater to various skill levels, from hobbyists looking to enhance their workshop capabilities to small businesses aiming to increase productivity without the substantial investment of a new CNC machine.

The benefits of these kits include cost-effectiveness, customization options for specific needs, and the ability to breathe new life into older, reliable equipment while incorporating modern manufacturing techniques.

- A CNC conversion kit is a cost-effective solution to transform a manual milling machine into a CNC system.

- It provides enhanced precision, flexibility, and efficiency in machining processes.

- The kit includes all the necessary components and instructions for installation.

- CNC conversion kits offer numerous benefits, including improved accuracy, increased productivity, and extended equipment lifespan.

- When choosing a CNC conversion kit, consider the compatibility with your machine model and specific requirements.

Benefits of CNC Conversion Kits

CNC conversion kits offer numerous benefits for machinists. Firstly, they provide improved accuracy and precision in machining operations, resulting in higher quality finished products. With CNC technology, you can achieve consistent and precise cuts, ensuring that each workpiece meets the desired specifications.

Additionally, CNC converted machines offer increased productivity and efficiency. By automating the machining processes, you can significantly reduce the time it takes to complete a job. CNC systems enable rapid tool changes, fast feed rates, and simultaneous multi-axis movements, allowing for faster production rates and reduced downtime.

CNC systems also enable the use of advanced machining techniques that aren’t possible with manual machines. With features like automatic tool-length measurement, tool wear compensation, and high-speed machining capabilities, you can push the limits of your manufacturing capabilities and achieve complex geometries with ease.

Furthermore, CNC conversion kits provide automation features that make complex tasks easier to execute. From programmable spindle speeds to automatic tool changers, these features streamline the machining process, reducing the need for manual interventions and human error.

Finally, by converting a manual machine to CNC, you extend the lifespan and usability of your equipment. Instead of investing in a new CNC machine, which can be costly, a conversion kit allows you to upgrade your existing machine, saving money while still reaping the benefits of CNC technology.

| Benefits of CNC Conversion Kits |

|---|

| Improved accuracy and precision |

| Increased productivity and efficiency |

| Ability to use advanced machining techniques |

| Automation features for easier execution of complex tasks |

| Extended lifespan and usability of existing equipment |

CNC Conversion Kit Installation Process

Converting your manual milling machine into a CNC system requires a precise installation process. By following the steps outlined below, you can successfully transform your machine into an automated powerhouse.

Step 1: Disassembly

The first step in the installation process is to disassemble your milling machine. This involves removing the lead screws and replacing them with ball screws and double nuts. The CNC conversion kit will come with all the necessary mechanical components for this step.

Step 2: Electronics Installation

Once the mechanical disassembly is complete, it’s time to install the electronic components. These components include stepper drivers, a controller, limit switches, and mechanical test probes. The specific installation steps will depend on the model of your milling machine and the electronics you choose for your CNC conversion.

Proper Alignment and Calibration

After the installation of mechanical and electronic components, it’s crucial to ensure proper alignment and calibration of the CNC system. This step ensures that your machine operates with optimal precision and accuracy. The installation guide provided with your CNC conversion kit will offer detailed instructions on alignment and calibration procedures.

By meticulously following the installation process and paying attention to alignment and calibration, you can successfully install your CNC conversion kit and unlock the full potential of your milling machine.

| Installation Process Summary |

|---|

| 1. Disassemble the milling machine by removing the lead screws and replacing them with ball screws and double nuts. |

| 2. Install the electronic components, including stepper drivers, a controller, limit switches, and mechanical test probes. |

| 3. Align and calibrate the CNC system to ensure optimal precision and accuracy. |

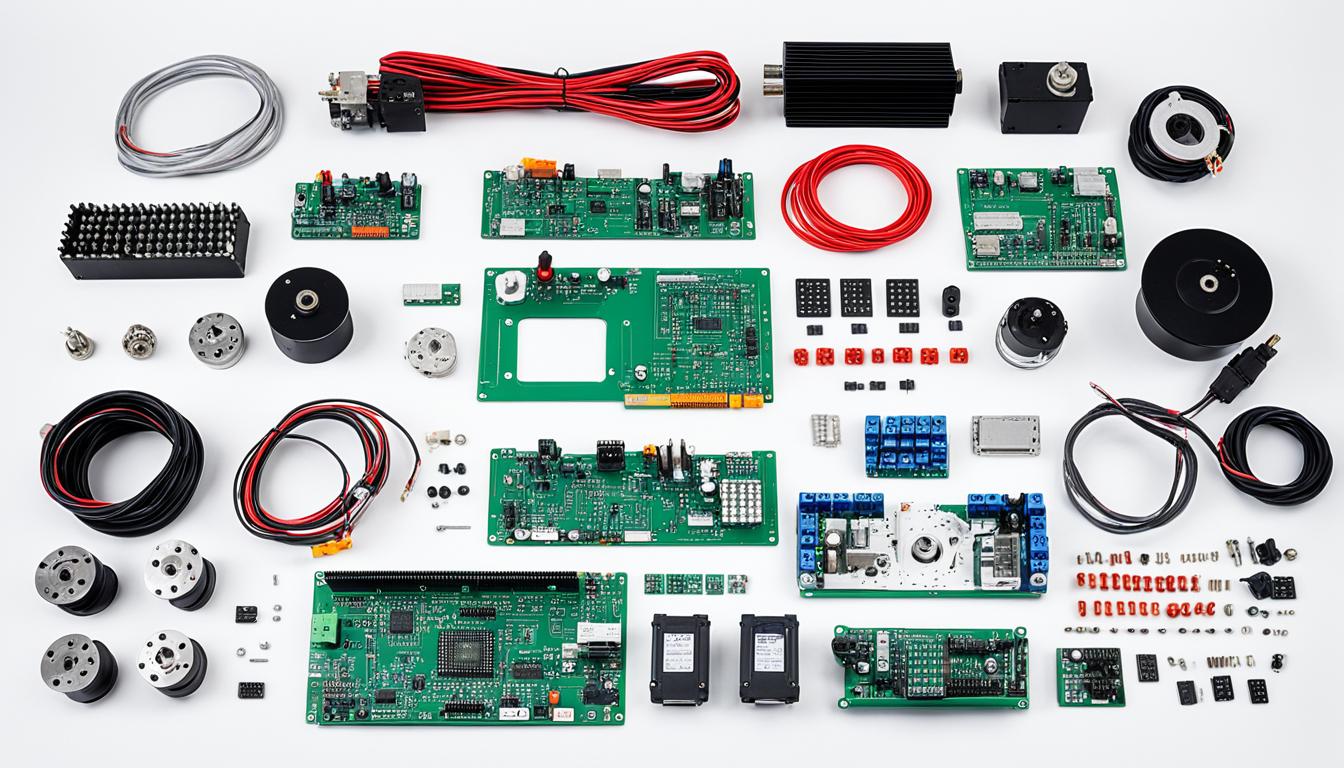

Components of a CNC Conversion Kit

A CNC conversion kit typically includes various components required for the conversion process. These components play a vital role in transforming a manual milling machine into a fully automated CNC system. Let’s take a closer look at the key components you can expect to find in a CNC conversion kit:

1. Ball Screws:

Ball screws are an essential component of a CNC conversion kit. They replace the original lead screws in a manual machine and provide smoother and more precise movement.

2. Double Nuts:

Double nuts are used in conjunction with ball screws to eliminate backlash, ensuring accurate and repeatable positioning during CNC operations.

3. Stepper Motors:

Stepper motors are responsible for driving the motion of the machine. These motors convert electrical pulses into precise mechanical movements, allowing for precise control and positioning.

4. Stepper Drivers:

Stepper drivers control the current and voltage supplied to the stepper motors. They are crucial for accurate motor movement and smooth operation of the CNC system.

5. Controller:

The controller is the brain of the CNC system. It interprets the G-code instructions and sends signals to the stepper drivers, ensuring coordinated and precise movements of the machine.

6. Limit Switches:

Limit switches are used to define the machine’s home position and limit its movement within specific boundaries. They help ensure safe and controlled operation.

7. Mechanical Test Probes:

Mechanical test probes are used for various purposes, such as setting the tool height and measuring workpiece dimensions. These probes aid in accurate machining and quality control.

8. Brackets and Mounts:

Depending on your specific milling machine model, the CNC conversion kit may include brackets and mounts to securely install the components onto your machine. These ensure proper alignment and stability.

It’s crucial to verify the compatibility of the components included in the CNC conversion kit with your machine model. Additionally, consider your specific needs and requirements to select the right kit for your CNC conversion project.

| Components | Function |

|---|---|

| Ball Screws | Replace lead screws, provide smoother and more precise movement. |

| Double Nuts | Eliminate backlash, ensure accurate and repeatable positioning. |

| Stepper Motors | Drive the motion of the machine, convert electrical pulses into mechanical movements. |

| Stepper Drivers | Control current and voltage supplied to the stepper motors, ensure accurate motor movement. |

| Controller | Interpret G-code instructions, send signals to stepper drivers for coordinated movements. |

| Limit Switches | Define machine’s home position, limit movement within specific boundaries. |

| Mechanical Test Probes | Set tool height, measure workpiece dimensions for accuracy and quality control. |

| Brackets and Mounts | Securely install components onto machine, ensure alignment and stability. |

The image above showcases some key components commonly found in CNC conversion kits.

Types of CNC Conversion Kits

When it comes to CNC machine conversion, there are various types of conversion kits available on the market. These kits cater to different machine types, such as lathes or mills, and offer varying levels of retrofitting to meet your specific requirements. Understanding the different types of CNC conversion kits can help you select the right one for your needs. Let’s explore some of the key types:

1. CNC Machine Conversion Kits

CNC machine conversion kits are designed to convert manual milling machines or lathes into CNC systems. These kits include all the necessary components, from ball screws and double nuts to stepper motors and drivers, to transform your manual machine into a fully automated CNC powerhouse. Whether you have a mill or a lathe, there are CNC machine conversion kits available for most machine models.

2. CNC Retrofit Kits

CNC retrofit kits focus on upgrading specific components or systems of an existing CNC machine. These kits allow you to enhance the performance and capabilities of your machine without replacing it entirely. Common retrofit kits include those for upgrading the spindle, control system, or adding advanced automation features. By investing in a CNC retrofit kit, you can optimize your machine’s functionality and keep up with evolving machining technologies.

3. CNC Upgrade Kits

CNC upgrade kits are similar to retrofit kits but typically include a broader range of components and upgrades. These kits offer a comprehensive solution for improving the overall performance and functionality of your CNC machine. From upgrading motors and controllers to adding high-precision measurement systems or advanced cooling systems, CNC upgrade kits provide the tools and components needed to take your machining capabilities to the next level.

When choosing a CNC conversion kit, consider the type of machine you have, the specific upgrades or modifications you want to make, and your budget. It’s essential to ensure that the kit you select is compatible with your machine model and meets your requirements. Consulting with experts or seeking advice from CNC conversion communities can also provide valuable insights and recommendations.

Having a clear understanding of the different types of CNC conversion kits available can help you make an informed decision and achieve the desired level of automation and performance for your CNC machine.

CNC Conversion Kit Guide and Recommendations

Converting a manual milling machine to CNC can be a complex process, especially for beginners. It’s advisable to follow a comprehensive guide or tutorial to ensure a successful conversion. Many online resources provide step-by-step instructions, tips, and recommendations for the CNC conversion process. Additionally, it can be helpful to seek advice from experienced machinists or join CNC conversion communities or forums to gain insights and learn from others’ experiences. When selecting a CNC conversion kit, it’s important to choose a reputable supplier and ensure the kit is compatible with your machine model.

| Recommended CNC Conversion Kits |

|---|

|

When it comes to choosing a CNC conversion kit, there are several reliable manufacturers and suppliers in the market. Some popular options include kits from Grizzly, Precision Matthews, Sieg, and Shop Fox. These kits are designed to fit specific lathe or mill models, providing a seamless conversion experience. It’s recommended to choose a kit that matches your machine model and meets your specific requirements. Additionally, consider factors such as the quality of components, customer reviews, and after-sales support when selecting a CNC conversion kit.

Recommended CNC Conversion Kits

When it comes to CNC conversion kits, there are several reliable manufacturers and suppliers that offer high-quality solutions. Some of the popular options in the market include kits from Grizzly, Precision Matthews, Sieg, and Shop Fox. These manufacturers specialize in providing CNC conversion kits that are specifically designed to fit various lathe or mill models, ensuring a seamless and successful conversion.

When choosing a CNC conversion kit, it is crucial to consider your machine model and ensure that the kit is compatible with it. Each manufacturer offers kits that are tailored to specific machine models, so it’s important to select one that matches your requirements. This ensures that you have all the necessary components and hardware to achieve a smooth and efficient conversion.

In addition to machine compatibility, other factors to consider include the quality of components, customer reviews, and after-sales support. The quality of components provided in the kit can greatly impact the overall performance and durability of your CNC system. Reading customer reviews and feedback can give you insights into the reliability and effectiveness of the kit. Lastly, having access to good after-sales support can be invaluable in case you encounter any issues during the installation or operation of your CNC conversion kit.