When buying a small milling machine, consider key factors such as size, power, precision, and versatility. Look for a machine with a sturdy cast iron or steel frame to minimize vibration and ensure stability. The spindle speed range should be suitable for various materials, typically between 100-2500 RPM. Opt for a model with a powerful motor, ideally 1-2 HP for hobby use.

Precision is crucial, so choose a machine with tight tolerances and minimal backlash. Ensure the table size and travel are adequate for your projects, with X, Y, and Z-axis movements of at least 12″, 6″, and 10″ respectively. Digital readouts (DRO) can greatly enhance accuracy and ease of use. Consider the tooling system, with R8 collets being a popular choice for small mills. Evaluate additional features like variable speed control, coolant systems, and work lights.

Lastly, factor in the availability of spare parts and technical support when selecting a brand. By carefully assessing these aspects, you can find a small milling machine that meets your specific needs and budget.

- Choosing the right small milling machine requires careful consideration of factors like size, power, and accuracy.

- There are three main types of milling machines: vertical, horizontal, and universal, each with unique features.

- Manual machines offer greater customization potential, while automatic machines provide higher accuracy and efficiency.

- Researching different milling machine brands and reading reviews can help you make an informed decision.

- Consider your budget and prioritize features that are essential for your specific milling needs.

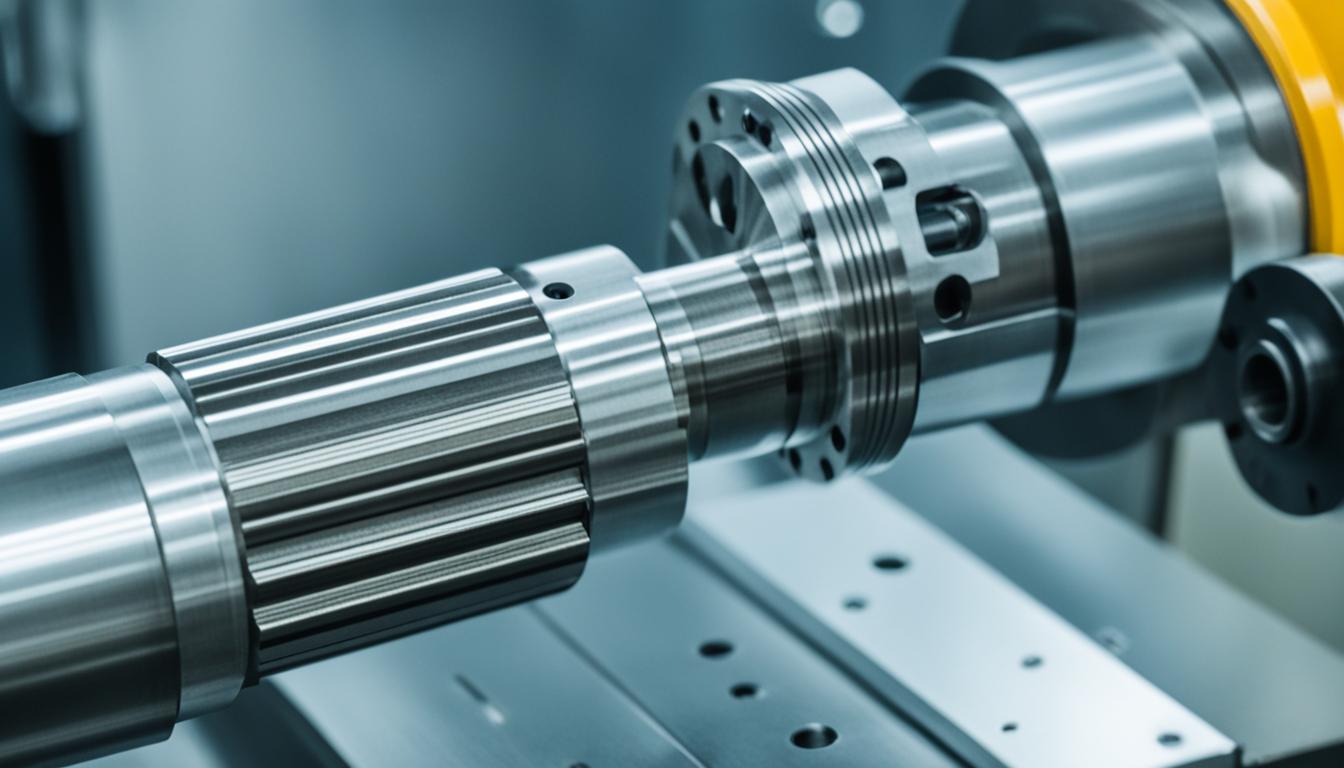

Types of Milling Machines: Vertical, Horizontal, and Universal

When it comes to milling machines, there are three main types to consider: vertical, horizontal, and universal. Each type has its own unique characteristics, making them suitable for different applications.

Vertical Milling Machine

The vertical milling machine is a versatile tool that features a vertically-oriented spindle. This design allows for the machine to perform a wide range of tasks, making it ideal for various industries. Whether you need to do simple drilling or complex cutting operations, a vertical milling machine can handle it with precision.

Horizontal Milling Machine

In contrast to the vertical milling machine, the horizontal milling machine has a horizontally-oriented spindle. This type of machine is particularly effective for heavy-duty cutting tasks that require the removal of a significant amount of material. It is commonly used in industries such as manufacturing and construction.

Universal Milling Machine

The universal milling machine offers the greatest flexibility among the three types. It is capable of operating on multiple axes, allowing for more complex and intricate machining operations. This versatility makes it a valuable tool in industries where precision and efficiency are paramount.

Understanding the differences between these types of milling machines is essential when choosing the right one for your needs. Whether you require versatility, heavy-duty cutting capabilities, or multi-axis operation, there is a milling machine that best suits your requirements.

Stay tuned for the next section, where we will explore the important factors to consider when buying a small milling machine.

Factors to Consider: Size, Power, and Accuracy

When selecting a small milling machine, it’s important to consider various factors such as size, power, and accuracy. These specifications play a crucial role in determining the machine’s performance and suitability for your specific machining needs.

Size

The size of the milling machine directly impacts its capacity and the size of parts it can handle. Larger machines can accommodate bigger workpieces, allowing for more versatility in your machining projects.

Motor Power and Spindle Speed

The motor power and spindle speed are key determinants of the machine’s cutting capabilities. Motor power dictates the torque, while the spindle speed determines the cutting force. These factors are essential for achieving precise and efficient machining results.

Table Size

The table size of a milling machine is an important consideration as it determines the overall workpiece capacity. A larger table size provides more space for securing and maneuvering the workpiece, allowing for greater flexibility in your machining operations.

Repeatability Accuracy

Repeatability accuracy is crucial for achieving precise and consistent machining results. It refers to the machine’s ability to return to a specific position accurately. This attribute is particularly important when working on intricate or complex projects that require high precision.

By evaluating these milling machine specifications, you can make an informed decision and find a small milling machine that meets your specific requirements.

Manual vs. Automatic Machines: Pros and Cons

When it comes to buying a small milling machine, one of the most crucial decisions to make is whether to opt for a manual or automatic machine. Each type has its own advantages and disadvantages, and understanding them will help you choose the right machine for your specific needs.

Advantages of Manual Machines

- Greater customization potential: Manual milling machines offer more control and flexibility, allowing experienced machinists to tailor their operations to meet specific requirements.

- Enhanced operator involvement: With manual machines, operators have a hands-on approach, which can improve the overall understanding of the milling process and contribute to skill development.

- Lower maintenance requirements: Manual machines tend to have simpler designs and fewer moving parts, resulting in reduced maintenance needs and costs.

Advantages of Automatic Machines

- Higher accuracy and consistency: Automatic milling machines utilize computer-guided operations, which ensure precise and consistent results, minimizing the chance of human error.

- Improved efficiency: Thanks to their automated operations, automatic machines save time and increase productivity, allowing for faster and more efficient machining.

- Reduced operator oversight: Automatic machines require less manual intervention, freeing up operators to focus on other tasks or operate multiple machines simultaneously.

Considerations

Choosing between manual and automatic machines depends on your specific needs, skill level, and the type of work you intend to undertake. If you value customization and have the expertise to operate a manual machine, it may be the right choice for you. On the other hand, if precision, efficiency, and reduced human oversight are crucial to your operations, an automatic machine would be more suitable.

| Manual Machines | Automatic Machines | |

|---|---|---|

| Advantages |

|

|

| Disadvantages |

|

|

By carefully considering your specific requirements and weighing the advantages and disadvantages, you can make an informed decision and select the milling machine that best suits your needs.

Consider Your Budget and Research Brands

When looking to purchase a small milling machine, one of the crucial factors to consider is your budget. Setting a clear budget will help you narrow down your options and ensure you find a machine that meets your financial requirements. However, it’s essential to strike the right balance between your budget and the quality of the machine. Keep in mind that investing in a reliable and durable milling machine from reputable brands often pays off in the long run, as these machines are built to last and deliver consistent performance.

In your research, don’t limit yourself to only brand name machines. While established brands are often associated with higher quality and reliability, there are many reputable non-brand name options available as well. By exploring reviews and considering the experiences of other users, you can gain valuable insights into the performance and durability of different milling machines. It’s always a good idea to prioritize reputable brands and models with positive reviews, as they have proven track records in delivering reliable and accurate results.

Reading milling machine reviews is an excellent way to gather information and understand the real-world experiences of users. Look for reviews that discuss the machine’s performance, precision, ease of use, and durability. Pay attention to feedback on customer service and the availability of spare parts, as these factors can significantly impact your overall experience and satisfaction.

By carefully considering your budget, researching milling machine brands, and reading reviews, you can make an informed decision and find a small milling machine that not only fits within your budget but also meets your needs and provides long-lasting value for your investment.