Expert maintenance strategies for CNC machine longevity focus on regular cleaning, lubrication, calibration, and software updates. Daily cleaning routines remove debris and prevent wear, while proper lubrication of moving parts reduces friction and extends component life. Regular calibration ensures precision and accuracy, maintaining optimal performance. Keeping software and firmware up-to-date enhances functionality and security. Implementing a structured maintenance schedule with routine inspections helps identify potential issues early, preventing costly breakdowns.

Training operators in proper machine handling and maintenance practices is crucial. Utilizing maintenance management software can streamline scheduling, track service history, and analyze performance data for continuous improvement. Advanced strategies include predictive maintenance using sensor data to anticipate failures, and precise alignments to maintain accuracy. Effective spare parts management minimizes downtime by ensuring quick repairs.

Creating an ideal operating environment with controlled temperature, humidity, and dust levels further protects the machine. By adhering to these comprehensive maintenance strategies, CNC machine operators can significantly extend their equipment’s lifespan, maintain high production quality, and optimize overall efficiency.

- Regular maintenance extends the life of CNC machines and improves performance.

- CNC coolant tanks consist of pumps, filters, and nozzles.

- Different types of coolant are used based on specific machining requirements.

- A well-structured maintenance schedule includes daily, weekly, monthly, and yearly tasks.

- Cleaning and disposal of CNC coolants ensure environmental protection and worker safety.

The Importance of Regular Coolant Tank Maintenance

Regular maintenance of CNC coolant tanks is vital for various reasons. It significantly extends the life of CNC machines, ensures optimal machine performance, improves the quality of the output, and reduces the risk of accidents and health hazards in the workplace. Each aspect of coolant tank maintenance contributes to a more efficient, safe, and productive machining environment.

Proper maintenance of CNC coolant tanks is essential for maximizing the longevity of CNC machines. Routine maintenance tasks, such as cleaning and changing the coolant, help prevent buildup of contaminants that can clog filters, pumps, and nozzles. This not only ensures uninterrupted coolant flow but also protects the internal components of the CNC machine from damage caused by poor coolant quality.

By regularly maintaining the coolant tank, CNC machine operators can optimize machine performance. Clean coolant promotes better heat dissipation, which prevents overheating and extends the life of CNC machine components. Well-maintained coolant also helps maintain consistent cutting temperatures, resulting in precision machining and improved product quality.

By investing time and effort into coolant tank maintenance, manufacturers can ensure quality assurance. Clean coolant reduces the risk of tool wear and part defects, resulting in higher accuracy and fewer production errors. This translates to improved customer satisfaction, increased productivity, and reduced rework, ultimately impacting the bottom line positively.

Safety is a top priority in any workplace, and regular coolant tank maintenance plays a crucial role in promoting a safe working environment. Dirty coolant can harbor bacteria and contaminants, which can lead to skin irritation, respiratory issues, and other health hazards. By regularly cleaning and changing the coolant, manufacturers can create a safer workplace for their employees.

Furthermore, routine coolant tank maintenance helps identify potential issues before they escalate into costly and time-consuming repairs. By inspecting pumps, filters, and nozzles regularly, operators can detect and address any signs of wear or malfunction early on. This proactive approach saves time, money, and resources, ensuring uninterrupted production and minimizing downtime.

Implementing a comprehensive coolant tank maintenance program is essential for maximizing the benefits mentioned above. A well-structured maintenance schedule should include tasks such as cleaning filters, checking coolant levels, inspecting pumps, and thoroughly cleaning the tank. It is also crucial to follow proper procedures for coolant disposal in compliance with environmental regulations.

The Benefits of Regular Coolant Tank Maintenance:

- Extends the life of CNC machines

- Ensures optimal machine performance

- Improves the quality of the output

- Reduces the risk of accidents and health hazards in the workplace

- Enhances safety

- Saves time and money by preventing costly repairs

- Promotes quality assurance

| Maintenance Tasks | Frequency |

|---|---|

| Inspect pumps, filters, and nozzles | Daily |

| Check coolant levels and quality | Weekly |

| Clean filters | Weekly |

| Thoroughly clean coolant tank | Monthly |

| Replace worn-out components | Yearly |

Understanding CNC Coolant Tanks

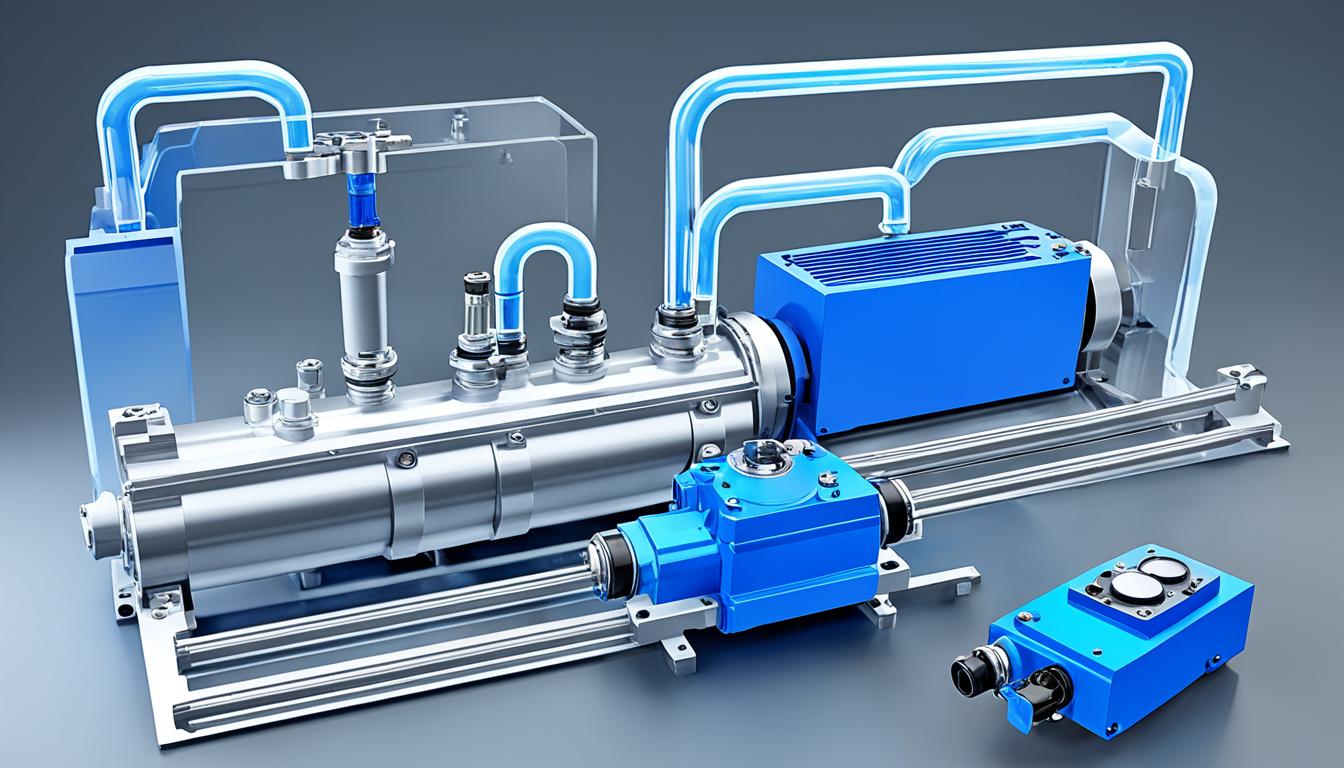

A CNC coolant tank is a crucial component of the machining process, responsible for maintaining optimal cooling and lubrication of the cutting tool and workpiece. To fully comprehend the functionality and significance of CNC coolant tanks, let’s explore their key components and the various types of coolants used in CNC machines.

Key Components of a CNC Coolant Tank

A CNC coolant tank is composed of several essential components that work together to ensure the proper circulation and filtration of coolant:

- Pumps: Pumps play a vital role in circulating the coolant throughout the system. They create the necessary pressure to deliver the coolant to the cutting tool and workpiece, ensuring optimal cooling and lubrication.

- Filters: Filters are responsible for removing contaminants from the coolant, such as metal shavings, chips, and debris. They help maintain the cleanliness and effectiveness of the coolant, minimizing the risk of tool wear and surface imperfections.

- Nozzles: Nozzles direct the flow of coolant onto the workpiece during the machining process. They ensure that the coolant is precisely directed to the cutting zone, enhancing cooling efficiency and chip evacuation.

Types of Coolants Used in CNC Machines

Different types of coolants are employed in CNC machines, each offering unique properties and advantages based on specific machining requirements:

- Oil-based Coolants: Oil-based coolants, such as cutting oils, provide excellent lubrication and cooling properties. They are commonly used for heavy-duty machining operations, especially for materials that generate high heat during the cutting process.

- Water-based Coolants: Water-based coolants, also known as emulsions or soluble oils, are a popular choice due to their cost-effectiveness and versatility. They are mixed with water to create a stable emulsion that provides cooling and lubrication properties suitable for a wide range of machining applications.

- Synthetic Coolants: Synthetic coolants are formulated using synthetic chemicals and are known for their superior cooling properties. They offer enhanced lubrication and heat dissipation capabilities, making them ideal for high-speed machining and intricate operations.

Understanding the components of a CNC coolant tank and the different types of coolants available allows operators to make informed decisions regarding coolant selection and maintenance. By ensuring the proper functioning and cleanliness of the coolant tank, CNC machine operators can optimize machining performance, extend tool life, and achieve high-quality results.

Structuring a Maintenance Schedule

A well-structured maintenance schedule is crucial for the longevity and efficiency of CNC coolant tanks. By regularly inspecting and maintaining the coolant tank, you can ensure that your CNC machine operates at its best and minimize the risk of breakdowns or performance issues.

Here is a breakdown of the various tasks that should be included in your maintenance schedule:

Daily Tasks

- Monitor coolant levels to ensure proper functioning of the coolant system.

- Check for any leaks or unusual noises that may indicate a problem with the coolant tank.

Weekly Responsibilities

- Inspect and clean the filters to remove any contaminants that can hinder coolant flow and affect machine performance.

- Ensure that the pumps are functioning correctly and have proper pressure to circulate the coolant.

- Check the nozzles and ensure they are not clogged or damaged, as this can affect the distribution of the coolant onto the workpiece.

Monthly Routines

- Thoroughly clean the coolant tank to remove any accumulated debris or sludge.

- Inspect the tank for any signs of wear or damage and replace any worn-out components as necessary.

Yearly Maintenance

- Perform a comprehensive inspection of the entire coolant system, including pumps, filters, nozzles, and tanks, to identify any potential issues.

- Replace any components that have reached their recommended service life or show signs of deterioration.

Following this maintenance schedule will ensure that your CNC coolant tank remains in optimal condition, maximizing the performance and lifespan of your CNC machine.

Cleaning and Disposal of CNC Coolants

Cleaning and maintaining CNC coolant tanks is essential for optimal machine performance and ensuring a safe working environment. Proper handling and disposal of CNC coolants are equally important steps in minimizing waste and protecting the environment.

To clean a CNC coolant tank, start by draining the old coolant and disposing of it responsibly. Next, scrub the interior of the tank to remove any residue or buildup. This helps to maintain the tank’s efficiency and prolong its lifespan.

To minimize waste, consider using bio-based or synthetic coolants, which often have a longer lifespan. These coolants can be filtered to extend their usability, reducing the frequency of coolant changes. Monitoring coolant concentration, pH, and temperature also helps optimize coolant performance and minimize waste.

When it comes to disposal, it’s crucial to follow proper methods to ensure environmental compliance and worker safety. Skimming off tramp oil and utilizing coolant recycling services are effective options for recycling CNC coolants. These processes allow for the recovery and reuse of coolant, minimizing waste and reducing the environmental impact.

Remember, responsible cleaning and disposal of CNC coolants not only contribute to waste minimization but also help create a safer and more sustainable machining environment.

See the table below for a summary of practices for cleaning and disposing of CNC coolants:

| Practices | Description |

|---|---|

| Choose bio-based or synthetic coolants | Opt for coolants that have a longer lifespan and can be filtered to extend usability. |

| Monitor coolant concentration, pH, and temperature | Regularly check these parameters to maintain optimal coolant performance. |

| Proper disposal methods | Follow regulations and guidelines for disposing of CNC coolants to protect the environment and ensure worker safety. |

| Consider recycling options | Explore services that allow for the recycling and reuse of CNC coolants, such as skimming off tramp oil or utilizing coolant recycling services. |

Safety Considerations for CNC Coolants

While CNC coolant plays a vital role in machining, it is important to prioritize safety and take necessary precautions to avoid potential risks associated with its usage. Two common safety concerns related to CNC coolants are skin irritation and inhalation hazards.

Skin Irritation

CNC coolants often contain additives that can irritate the skin upon contact. It is important for machine operators and maintenance personnel to handle coolants with care to prevent skin irritation or allergic reactions.

To minimize the risk of skin irritation:

- Wear appropriate personal protective equipment (PPE) such as gloves and safety goggles when working with coolant.

- Thoroughly wash hands and exposed skin after handling coolant.

- Follow manufacturer’s instructions and safety guidelines when using and disposing of coolant.

Inhalation Hazards

During machining operations, CNC coolants can produce a fine mist that, when inhaled, may pose hazards to respiratory health. This mist can contain harmful particles or additives that can irritate the airways and lungs.

To minimize the risk of inhalation hazards:

- Ensure proper ventilation in the machining area to disperse the coolant mist.

- Use mist collectors or fume extraction systems to capture and remove coolant mist from the air.

- Wear respiratory protection, such as masks or respirators, when working in areas with high coolant mist concentration.

By implementing these safety measures, operators and maintenance personnel can minimize the risks associated with CNC coolants and ensure a safer working environment.

Troubleshooting Common Coolant Tank Issues

Contamination in CNC coolant tanks is a prevalent issue that can significantly impact the performance and effectiveness of the coolant. To ensure the health of your machines and the quality of the coolant, it’s essential to address and resolve these problems promptly. This section will cover the detection, containment, remediation, and prevention of coolant contamination.

Detection Methods

There are various methods for detecting coolant contamination in CNC machines. Visual checks can help identify visible particles or discoloration in the coolant, indicating potential contamination. Refractometer tests measure the refractive index of the coolant, providing insights into its cleanliness and concentration. Monitoring the pH level of the coolant can also help identify any deviations from the optimal range, which may indicate contamination.

Containment and Remediation

Once coolant contamination is detected, it’s crucial to contain the issue to prevent further damage to the machine and the coolant. Containment measures may involve stopping the use of contaminated coolant and draining the tank. Remediation techniques, such as filtering the coolant or using additives to remove contaminants, can help restore the coolant’s quality. Timely containment and remediation can minimize the impact of contamination on machine performance and product quality.

Prevention Measures

Preventing coolant contamination is essential for maintaining the longevity of CNC machines and ensuring consistent coolant effectiveness. Implementing preventive measures can include regular maintenance, such as cleaning and replacing filters, to keep the coolant clean and free from contaminants. Additionally, monitoring coolant concentration, pH, and temperature can help identify potential issues before they escalate. By proactively preventing coolant contamination, you can minimize downtime and maximize productivity.

Fixing Poor Coolant Circulation

Poor coolant circulation can significantly impact the performance of CNC machines. However, troubleshooting and resolving circulation issues can be relatively straightforward. By diagnosing the flow, addressing blockages, performing pump maintenance, and conducting electrical checks, you can restore proper coolant circulation and ensure efficient and safe operation of your CNC machine.

Diagnosing the Flow

Before troubleshooting poor coolant circulation, it is crucial to diagnose the flow and identify any potential issues. Start by examining the coolant flow throughout the CNC system to determine if there are any noticeable interruptions or abnormalities.

Addressing Blockages

Blockages in the coolant system can disrupt the flow and impede proper circulation. Inspect the coolant lines, filters, and nozzles for any obstructions or debris. Clean or replace clogged filters and remove any blockages to restore optimal coolant circulation.

Performing Pump Maintenance

The pump plays a vital role in circulating coolant throughout the CNC system. Check the pump for air pockets, as these can disrupt the flow. Inspect the pump for any signs of wear and tear, such as leaks or damaged components. Regular pump maintenance, including lubrication and cleaning, helps ensure its proper functioning and reliable coolant circulation.

Conducting Electrical Checks

Electrical connections are crucial for the operation of the coolant pump and other components in the CNC system. Examine the electrical connections, including wires, connectors, and switches, to confirm they are secure and free from damage. Address any electrical issues promptly to prevent disruptions in coolant circulation.

By troubleshooting and resolving poor coolant circulation, you can optimize the performance of your CNC machine and minimize the risk of overheating or other coolant-related issues. Regular maintenance and monitoring of coolant circulation are essential to ensure the longevity and efficiency of your CNC system.

Enhancing the Longevity of CNC Coolant Tanks

Ensuring CNC coolant tank longevity is essential for maintaining the optimal performance of CNC machines. One preventive measure that can significantly contribute to this goal is performing rewiring every 12 years. This preventive rewiring helps prevent wear and tear, ensures compatibility with new technology, enhances safety, reduces maintenance costs, and ensures regulatory compliance.

The rewiring process involves removing old cables and installing new energy chains and cables. By replacing outdated wiring, you can minimize the risk of electrical failures, voltage fluctuations, and other issues that can compromise the performance and lifespan of your CNC coolant tank.

Regular inspections are recommended to assess the condition of the wiring and determine if a rewire is necessary. Identifying potential issues early on allows you to take proactive measures and prioritize the longevity and efficiency of your CNC coolant tank.

By investing in preventive rewiring, you can address technological obsolescence, enhance safety, reduce maintenance costs, and comply with regulatory standards. Don’t neglect this crucial aspect of CNC machine maintenance to ensure the longevity of your coolant tanks.

Machine Relocation and Maintenance

When it comes to relocating CNC machines, proper planning and a detailed plan are crucial to minimize downtime and ensure the reliability of the machine. At Unisign, we understand the challenges involved in machine relocation, and we offer comprehensive assistance to make the process hassle-free for our customers.

Alongside machine relocation, preventive maintenance plays a vital role in maximizing the long-term reliability and efficiency of CNC machines. Regular inspections and repairs are essential to identify and address potential issues before they turn into costly downtime events. By implementing a proactive maintenance strategy, machine reliability can be significantly improved, ultimately leading to increased productivity and reduced expenses.

At Unisign, we prioritize the needs of our customers and strive to provide top-notch machine maintenance services. Our team of experienced technicians is well-equipped to handle all aspects of machine maintenance, including inspections, repairs, and optimizations. With our expertise, you can rest assured that your CNC machines will operate at their peak performance, minimizing the risk of unexpected breakdowns and maximizing your production efficiency.