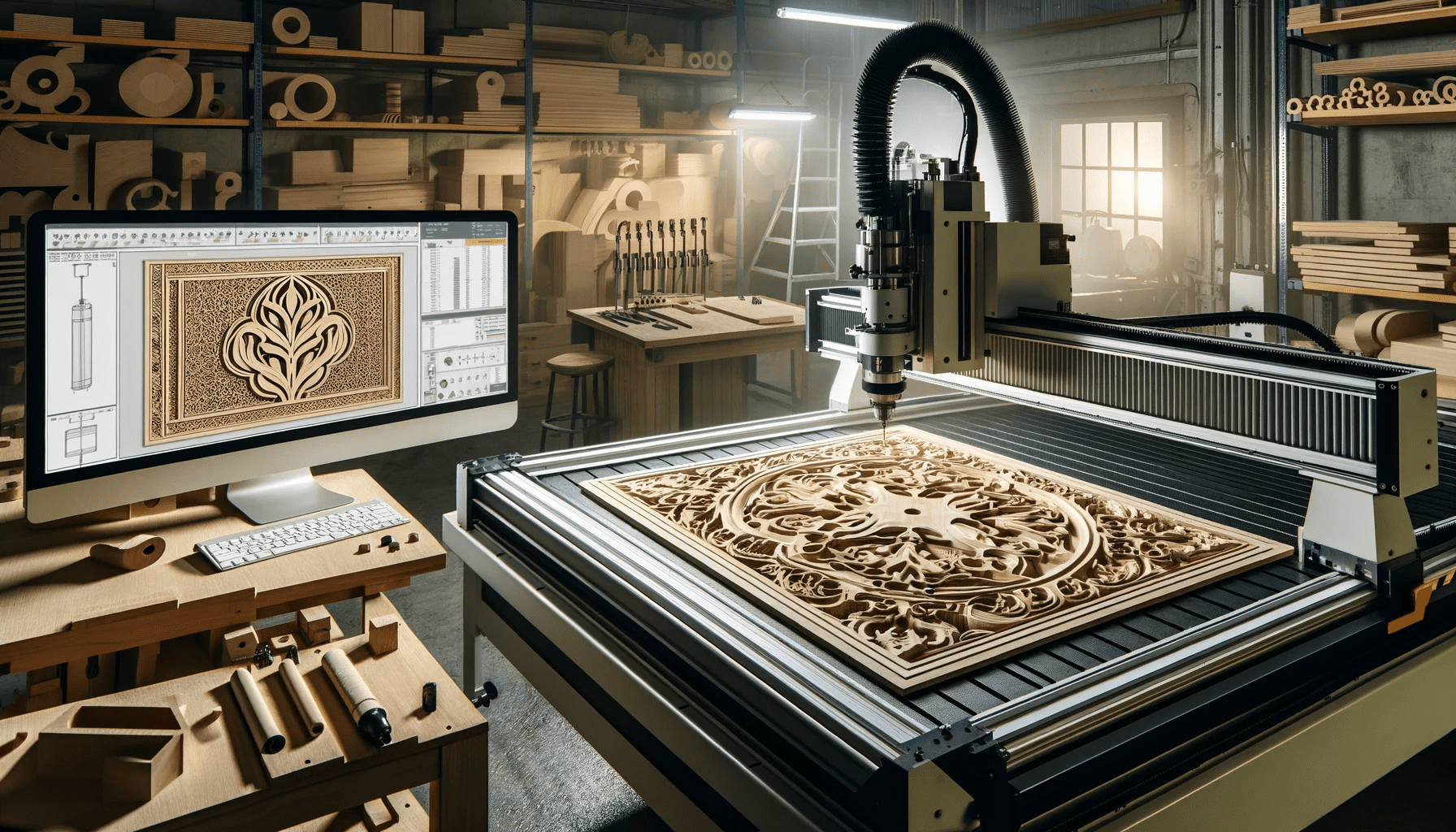

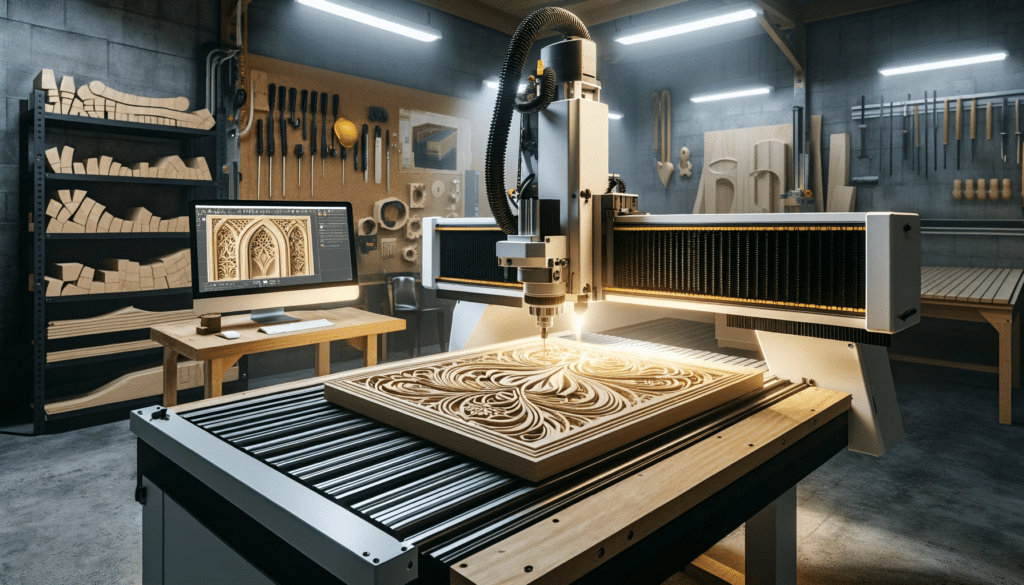

CNC wood routers have revolutionized the creation of beautiful woodwork projects, offering precision, efficiency, and versatility to both professional woodworkers and hobbyists. These computer-controlled machines use rotating cutting tools to carve, engrave, and shape wood into intricate designs and functional pieces. With a CNC wood router, craftsmen can produce complex patterns, 3D reliefs, custom furniture components, and decorative elements with remarkable accuracy and consistency. The process typically involves designing the project using CAD software, converting the design into machine-readable code, and then allowing the CNC router to execute the cutting and carving operations.

This technology enables woodworkers to tackle projects that would be challenging or time-consuming to complete by hand, such as detailed inlays, personalized signs, or repeating patterns across large surfaces. CNC wood routers also excel at producing multiple identical pieces, making them ideal for small-scale production runs or creating matching sets of furniture or decor items. By combining traditional woodworking skills with modern CNC technology, artisans can push the boundaries of their craft, creating stunning and unique wooden masterpieces that blend artistry with precision engineering.

The Benefits of Using a CNC Wood Router

There are many benefits of using a CNC wood router. Perhaps the most obvious benefit is the increased accuracy that a CNC wood router can provide. When working with wood, even the slightest mistake can result in an unusable piece. By using a CNC wood router, you can be assured that your cuts will be precise.

Another benefit of using a CNC wood router is the increased speed. CNC wood routers can cut much faster than a human can, meaning that you can get your project done in a fraction of the time. This is especially beneficial if you are working on a tight deadline.

CNC wood routers also have the ability to create repetitive cuts. This means that if you need to make the same cut multiple times, you can program the router to do so without having to manually make each cut. This can save a lot of time, especially if you are working on a large project.

The benefits of using a CNC wood router are numerous. If you are considering using one for your next project, be sure to take advantage of all the benefits it has to offer!

Using the Right Techniques for CNC Wood Router Projects

CNC wood routers are amazing machines that can create detailed and intricate designs in wood. However, in order to get the most out of your CNC wood router, it is important to use the right techniques. In this blog post, we will share with you some tips on how to get the most out of your CNC wood router projects.

One of the most important things to keep in mind when using a CNC wood router is to take your time. This is not a machine that you can just quickly zip through a project. The more time you take to slowly and carefully create your design, the better the final product will be.

Another important tip is to use the right bits for your project. Different bits will create different results, so it is important to use the right bit for the job. If you are unsure which bit to use, there are many resources available online that can help you make the decision.

It is also important to make sure that you have a good understanding of the software that you are using. The better you understand the software, the easier it will be to create complex and detailed designs. There are many tutorials available online that can help you learn the ins and outs of the software.

By following these tips, you will be well on your way to creating beautiful and intricate designs with your CNC wood router.

Tips for Selecting the Best CNC Wood Router for Your Needs

A CNC wood router is a powerful tool that can be used to create beautiful and intricate designs in wood. But with so many different models and brands on the market, it can be tough to know which one is right for your needs. In this blog post, we’ll give you some tips for choosing the best CNC wood router for your project requirements.

Consider the size of the router. If you’re only going to be working on small projects, then a smaller router will be sufficient. But if you plan on working on larger pieces of wood, then you’ll need a router that has a large enough bed to accommodate your work.

Think about the features that you need. Some routers come with built-in dust collection systems, while others have more powerful motors that can handle tougher cuts. Consider what you’ll be using your router for and choose the model that has the features that you need.

Don’t forget to factor in the price. Routers can range in price from a few hundred dollars to several thousand dollars. It’s important to find a model that fits your budget and that has the features that you need.

By following these tips, you should be able to find the best CNC wood router for your needs. With the right router, you’ll be able to create beautiful woodworking projects that will be the envy of your friends and family.

What Can You Create with a CNC Wood Router?

A CNC wood router is a versatile machine that can be used to create a wide variety of products. Here are just a few examples of what you can create with a CNC wood router:

- Cabinets: You can use a CNC wood router to create custom cabinets for your home or business.

- Furniture: A CNC wood router can be used to create custom furniture pieces.

- Signs: A CNC wood router can be used to create custom signs for your business or home.

- Decorative Pieces: A CNC wood router can be used to create decorative pieces for your home or office.

There are endless possibilities when it comes to what you can create with a CNC wood router. If you can imagine it, chances are you can create it with a CNC wood router.

Maintaining and Caring for Your CNC Wood Router

As a woodworker, you know that having a reliable and well-maintained CNC wood router is essential to your success. Here are some tips on how to maintain and care for your CNC wood router so that it will last for years to come:

It is important to regularly clean your CNC wood router. This will help to prevent dust and debris from build up and clogging the machine. You can use a soft cloth or brush to dust off the machine, and be sure to pay special attention to the bits and spindles.

You should lubricate your CNC wood router regularly. This will help to keep the moving parts working smoothly and prevent wear and tear. You can use a light machine oil or lubricant specifically designed for CNC routers.

It is important to keep your CNC wood router properly aligned. Over time, the router bits can become misaligned, which can cause problems with your cuts. You can use a laser alignment tool to make sure that the bits are properly aligned.

You should regularly check the condition of your CNC wood router bits. dull or damaged bits can cause problems with your cuts, so it is important to replace them as needed. You can find replacement bits at most woodworking stores.

By following these simple tips, you can ensure that your CNC wood router will last for many years to come.

Choosing the Right Cutting Bits for CNC Wood Router Projects

When it comes to CNC wood router projects, choosing the right cutting bits is crucial. The type of cutting bit you use will determine the quality of the finished project, as well as how long it takes to complete the project. In this blog post, we’ll give you a rundown of the different types of cutting bits available for CNC wood routers, so you can choose the right ones for your next project.

The most common type of cutting bit for CNC wood routers is the spiral fluted bit. These bits are designed to quickly remove material from the workpiece, and they’re ideal for projects that require a lot of material to be removed. However, spiral fluted bits can produce rough edges, so they’re not always the best choice for projects that require a high level of detail.

Another popular type of cutting bit is the ball-nose bit. These bits are designed for creating smooth, curved surfaces, and they’re perfect for projects that require intricate details. However, ball-nose bits can be more difficult to control than spiral fluted bits, so they’re not always the best choice for beginners.

No matter what type of CNC wood router project you’re working on, we have the perfect cutting bits for the job. Shop our selection of cutting bits today and get everything you need to complete your project quickly and easily.

Troubleshooting Common CNC Wood Router Problems

If you’re new to the world of CNC wood routers, the vast array of options and add-ons can be daunting. But don’t worry, we’re here to help you sort through the options and find the best machine for your needs. In this blog post, we’ll also walk you through some common CNC wood router problems and how to troubleshoot them.

One of the most common problems with CNC wood routers is inaccuracy. If your cuts are coming out slightly off, there are a few things you can check. First, make sure that your machine is properly calibrated. If it’s not, the cuts will be off. Second, check the condition of your bits. If they’re dull or damaged, they can cause inaccuracies. Finally, make sure that your material is properly secured. If it’s not, it can move during the cutting process, resulting in inaccurate cuts.

Another common problem is burning. If you’re noticing that your bits are burning through your material, there are a few things you can do to fix it. First, check your bits. If they’re worn out or damaged, they’ll need to be replaced. Second, adjust your speed and feed rates. If you’re cutting too fast or feeding the material too quickly, it can cause burning. Finally, make sure you’re using the proper lubricant. If you’re not, it can cause burning and other damage to your bits.

If your machine is vibrating excessively, it can cause poor cutting quality and even damage your bits. To fix this problem, first check for loose bolts and tighten them if necessary. Next, check the condition of your bearings. If they’re worn out, they’ll need to be replaced. Finally, check the condition of your spindle. If it’s damaged, it will need to be repaired or replaced.

Finally, if your machine is making strange noises, it’s important to investigate the source of the noise. Often, strange noises are caused by loose parts or damaged bearings. If you can’t identify the source of the noise, it’s best to bring your machine to a qualified technician for diagnosis and repair.

Hopefully this blog post has helped you troubleshoot some common CNC wood router problems. If you have any other questions or concerns, please don’t hesitate to contact us. We’re always happy to help!

Exploring the Design Software Options for CNC Wood Router Projects

When it comes to woodworking, a CNC wood router can be an incredibly versatile and powerful tool. But in order to get the most out of your router, you need to have the right software. There are a wide variety of software options available for CNC wood routers, and each has its own strengths and weaknesses. In this blog post, we’ll explore some of the most popular design software options for CNC wood router projects so that you can make an informed decision about which one is right for you.

One of the most popular design software options for CNC wood routers is Vectric Aspire. Aspire is a powerful 2D and 3D design software that is specifically tailored for use with CNC wood routers. It includes a wide variety of features and tools that make it easy to create detailed and complex designs. Aspire is also relatively easy to learn and use, which makes it a good option for those who are new to using design software.

Another popular design software option for CNC wood routers is Carbide Create. Like Aspire, Carbide Create is tailored for use with CNC wood routers and includes a wide variety of features and tools. However, Carbide Create is a more simplistic design software that is better suited for those who are new to using design software or for those who only need to create basic designs.

Finally, there is Autodesk Fusion 360. Fusion 360 is a more general purpose 3D design and CAD software that can be used for a wide variety of projects, including woodworking. Fusion 360 includes a wide range of powerful features and tools, but it can be more difficult to learn and use than some of the other design software options. However, if you are already familiar with Autodesk products, then Fusion 360 may be the right choice for you.

No matter which design software option you choose, you’ll be able to create amazing designs for your CNC wood router projects. So take some time to explore the different options and find the one that best meets your needs.

How to Find Inspiration for CNC Wood Router Projects

Are you interested in finding inspiration for CNC wood router projects? If so, read on for some tips!

CNC wood routers are amazing machines that can create beautiful and intricate designs. However, it can be difficult to know where to start when it comes to finding inspiration for your next project.

One great way to find inspiration is to look at other people’s work. There are many online galleries that showcase the work of CNC wood routers. You can also search for specific projects that you would like to recreate.

Another great way to find inspiration is to attend trade shows or conventions that focus on CNC wood routers. This is a great way to see the latest and greatest that the industry has to offer. You can also talk to other CNC wood router users and get their input on what projects they have completed.

Don’t be afraid to experiment! Sometimes the best way to find inspiration is to just start playing around with the machine and seeing what it is capable of. You may be surprised at the results you can achieve.

Finding Resources for Your CNC Wood Router Projects

If you’re like most people, you probably don’t have a lot of experience with CNC wood routers. That’s okay! These machines can be intimidating, but with a little research and practice, you’ll be able to use them to create amazing projects.

One of the best things about CNC wood routers is that they can be used for a variety of projects. Whether you want to create a new piece of furniture or you’re looking to add some decorative elements to your home, a CNC wood router can help you achieve your goals.

Of course, before you can start using your CNC wood router, you need to find the resources you need to get started. Here are a few tips to help you find the resources you need for your CNC wood router projects:

Check out online forums

There are many online forums devoted to CNC wood routers. These forums are a great place to ask questions, get advice, and find resources for your projects.

Watch YouTube videos

YouTube is a great resource for learning how to use a CNC wood router. There are many videos that show you how to set up and use these machines. Watching these videos can give you a good overview of what you need to do to get started with your own projects.

Read articles and tutorials

There are also many articles and tutorials available online that can teach you how to use a CNC wood router. These resources can be extremely helpful, especially if you’re new to using these machines.

Find a local CNC wood router group

If you live in an area with a large woodworking community, there’s a good chance there’s a CNC wood router group nearby. Joining one of these groups can be a great way to get started with your projects. You can find these groups by doing a quick search online.

Take a class

There are also many classes available that can teach you how to use a CNC wood router. These classes can be a great way to get hands-on experience with these machines.

Finding the resources you need for your CNC wood router projects doesn’t have to be difficult. With a little bit of research, you can easily find the information and resources you need to get started.