The cost of a CNC router varies widely based on several factors. On average, CNC routers range from $2,768 for hobby-level machines to $12,098 for advanced 5-axis models. Entry-level desktop CNC routers can be found for as low as $150-$500, while professional-grade machines can cost $50,000-$100,000. The price is influenced by table size, spindle power, axis configuration, and additional features like automatic tool changers.

For example, 3-axis CNC routers average $3,689, while 4-axis types with rotary capabilities cost around $9,789. Software, router bits, dust collection systems, and shipping can add $2,000-$3,000 to the total cost. Ongoing expenses include maintenance (about $200 per month for machines running 10 hours daily) and router bits ($80-$160 monthly).

When budgeting, consider installation costs ($200-$1000 per day), training fees (up to $1,000 per day), and potential floor reinforcement for larger machines. Used CNC routers offer savings, averaging $2,132 compared to $7,836 for new models, but may incur higher maintenance costs.

- The average price of a CNC router is between $1,000 and $100,000.

- Factors such as machine size, material compatibility, number of axes, and brand influence the cost.

- Using a CNC router cost calculator can provide a more accurate estimate.

- Consider your specific needs, budget, and research different models before making a decision.

- Buying options include new machines, used machines, or building your own DIY CNC router.

Factors Affecting the Price of CNC Routers

When considering the cost of CNC routers, several factors come into play. Understanding these factors can help you make an informed decision and find the best CNC router for your budget. Let’s explore the key elements that can impact the price of CNC routers:

- Size of the Machine: The size of the CNC router is a significant factor in determining its price. Generally, smaller machines are more affordable compared to larger ones.

- Type of Material: CNC routers that can work with a wider range of materials, such as wood, metal, and plastic, tend to have a higher price tag. The versatility of the machine increases its cost.

- Number of Axes: Machines with more axes typically have a higher price. Additional axes provide increased precision and versatility, making them ideal for complex projects.

- Brand: Well-known brands in the CNC router industry often command higher prices due to their reputation for quality and reliability. However, there are also affordable options from lesser-known brands that offer reliable performance.

- Level of Automation: CNC routers with advanced automation features, such as tool changers and automatic material handling, can be more expensive. These features enhance productivity but come at an additional cost.

- Quality of Components: The quality of components used in a CNC router can affect its price. Higher-quality components tend to be more durable and precise, contributing to a higher overall cost.

- Country of Origin: The country of origin can influence the pricing of CNC routers. Machines manufactured in certain countries may be more affordable due to lower production costs, while others may be higher-priced due to specific manufacturing advantages.

By considering these factors, you can evaluate different CNC router options and find the best fit for your needs and budget.

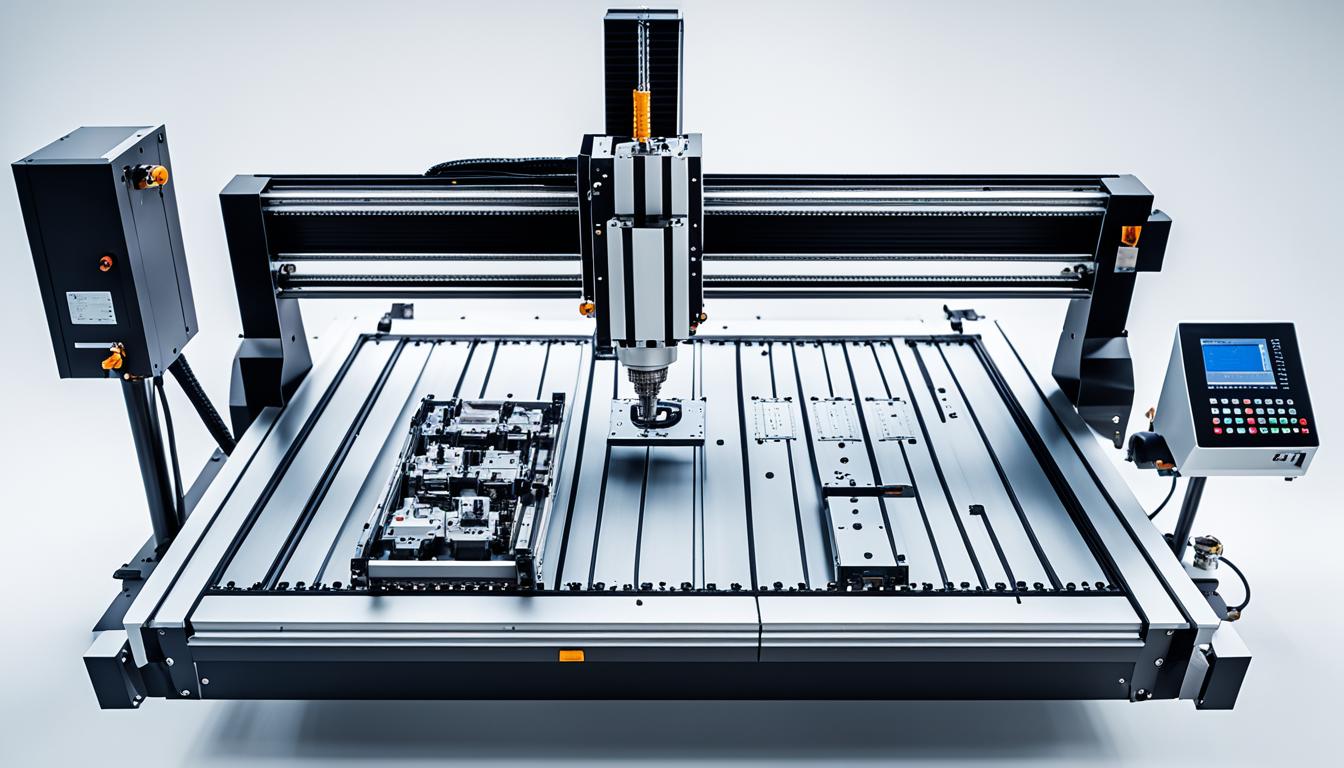

The image above provides a visual representation of an affordable CNC router, aligning with the topic of affordable CNC routers.

| CNC Router Feature | Average Price Range |

|---|---|

| Small CNC Router | $1,000 – $5,000 |

| Midsize CNC Router | $5,000 – $20,000 |

| Large CNC Router | $20,000 – $100,000 |

The table above showcases the average price ranges for different sizes of CNC routers, providing further insights into the budget considerations when selecting a machine.

Types of CNC Router Machines and Their Costs

When it comes to CNC router machines, there are various types available on the market. Each type caters to different needs and comes with its own cost range. Whether you’re a hobbyist or a professional, there’s a CNC router machine out there for you.

Hobbyist CNC Routers

Hobbyist CNC routers are more affordable options for those just starting or pursuing their hobbies. These machines offer basic functionalities and are suitable for smaller projects. The prices for hobbyist CNC routers typically range from $1,000 to $3,000. They provide a good starting point for beginners without breaking the bank.

Professional CNC Routers

Professional CNC routers are designed for advanced users who require more capabilities and features. These machines are ideal for businesses or individuals looking for precision and efficiency in their projects. The cost of professional CNC routers varies depending on their size and functionalities, with prices ranging from $5,000 to $100,000. While they may be more expensive, they offer increased reliability and performance for high-demand applications.

Aside from the general types of CNC routers, there are also specialized machines tailored for specific applications.

CNC Woodworking Routers

CNC woodworking routers are popular options for those working with wood materials. These machines offer reliable precision and versatility, making them suitable for various woodworking projects. The prices for CNC woodworking routers typically range from $2,500 to $20,000, depending on the size and functionality. They provide an excellent balance between cost and performance for woodworking enthusiasts and professionals.

CNC Stone Engraving Machines

If you work with stone materials and require intricate engravings, CNC stone engraving machines are the perfect choice. These specialized machines are designed to handle the unique challenges of working with stone. The cost of CNC stone engraving machines can range from $5,000 to $8,000, depending on the specific features and capabilities.

To help you make an informed decision and estimate the cost of a CNC router machine, you can use a CNC router cost calculator. These online tools take into account various factors such as machine type, size, and functionality to provide you with a more accurate estimate. By considering your specific needs and budget, you can find the right CNC router machine that suits your requirements.

| Type of CNC Router | Price Range |

|---|---|

| Hobbyist CNC Routers | $1,000 – $3,000 |

| Professional CNC Routers | $5,000 – $100,000 |

| CNC Woodworking Routers | $2,500 – $20,000 |

| CNC Stone Engraving Machines | $5,000 – $8,000 |

Considerations when choosing a CNC router machine

When it comes to choosing a CNC router machine, several key considerations can help you make an informed decision. By taking into account your specific needs and requirements, you can select a machine that aligns with your goals. Here are some factors to consider:

Size of the machine

The size of the CNC router machine is an essential factor to consider. Determine the available workspace and the dimensions of the materials you will be working with. This will ensure that the machine can accommodate your desired projects.

Type of material

Consider the type of material you will be working with. CNC routers can handle various materials such as wood, metal, or plastic. Ensure that the machine you choose is compatible with your intended materials to achieve the best results.

Level of automation

The level of automation required is another crucial consideration. CNC router machines can range from manual to fully automated systems. Decide whether you need a machine that offers more automated features or if a manual machine suits your needs.

Budget

Your budget is an important factor in choosing a CNC router machine. Consider how much you are willing to invest and explore different options within your price range. Remember to factor in additional expenses such as shipping, installation, accessories, and maintenance.

Research different brands and models

Researching different brands and models will help you find the best CNC router machine for your needs. Look for reputable brands that offer reliable machines with good customer support. Read reviews, compare specifications, and consider the reputation of the manufacturer.

By considering these factors and utilizing a CNC router cost calculator, you can make an informed decision and find a CNC router machine that meets your requirements.

CNC Router Feature Comparison

| Feature | Basic Model | Mid-Range Model | Premium Model |

|---|---|---|---|

| Working Area | 2’x2′ | 4’x4′ | 4’x8′ |

| Number of Axes | 3 | 4 | 5 |

| Spindle Power | 1.5 HP | 3 HP | 5 HP |

| Control System | Basic | Intermediate | Advanced |

| Price Range | $2,000 – $5,000 | $7,000 – $15,000 | $18,000 – $30,000+ |

Buying options for CNC router machines

When it comes to purchasing a CNC router machine, you have several buying options to consider. One option is to buy a new machine directly from a manufacturer or authorized dealer. New machines often come with a warranty and ongoing support, ensuring peace of mind. While new machines can be more expensive, they offer the latest technology and advanced features, making them a worthwhile investment for those who prioritize cutting-edge capabilities.

If budget is a concern, another option is to explore the used CNC router machine market. Used machines can be more affordable compared to their new counterparts. However, it is crucial to conduct thorough research and inspections before making a purchase. This helps ensure that the used machine is in good working condition and doesn’t require extensive repairs or maintenance. Buying a used CNC router can be a cost-effective solution for those who are willing to put in the extra effort and due diligence.

For individuals with the necessary skills and resources, building a DIY CNC router machine is another viable option. Building your own machine allows for customization and cost savings, especially if you already have some of the necessary components or materials. However, it’s important to be aware that building a DIY CNC router requires technical expertise and may take considerable time and effort. It can be a rewarding endeavor for those who enjoy hands-on projects and want more control over the machine’s design and functionality.