No, milling and CNC (Computer Numerical Control) are not the same. Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. It is a subtractive manufacturing process, meaning material is removed from the workpiece to create the desired shape. CNC is a type of automated machining process that uses computer-controlled machines to perform a variety of machining operations. CNC machines are programmed with a set of instructions that tell the machine how to move and what operations to perform. CNC machines can be used to perform a variety of machining operations, including milling, drilling, tapping, and turning. While CNC machines can be used to perform milling operations, they are not the same as milling. CNC machines are more precise and can be used to create complex shapes and patterns that would be difficult or impossible to achieve with traditional milling machines.

What is the difference between milling and cutting?

Milling and cutting are two processes used in machining, a manufacturing process that involves the use of specialized tools to shape and form materials. The main difference between milling and cutting is that milling is a more complex process that involves the use of multiple cutting tools to shape and form the material, while cutting is a simpler process that only requires one cutting tool.

Milling is a machining process that uses a rotating cutting tool to shape and form materials. The cutting tool is usually a multi-point cutting tool, such as an end mill, which has multiple cutting edges. The cutting tool is moved in a linear or rotary motion to remove material from the workpiece. Milling is used to create complex shapes and features, such as slots, grooves, and contours.

Cutting is a machining process that uses a single cutting tool to shape and form materials. The cutting tool is usually a single-point cutting tool, such as a drill bit, which has a single cutting edge.

Is CNC milling difficult?

CNC milling can be a difficult process to master, depending on the complexity of the project. It requires a great deal of knowledge and skill to be able to program the CNC machine to produce the desired results. The operator must be familiar with the CNC machine’s programming language, as well as the various tools and techniques used in the milling process. Additionally, the operator must be able to troubleshoot any issues that may arise during the milling process.

The complexity of the project will also determine the difficulty of the CNC milling process. Projects that require intricate details and precise measurements will require more skill and knowledge than simpler projects. Additionally, the type of material being milled will also affect the difficulty of the process. Harder materials, such as steel, require more skill and knowledge to mill than softer materials, such as aluminum.

Overall, CNC milling can be a difficult process to master, but with the right knowledge and skill, it can be done successfully.

What does a milling machine do?

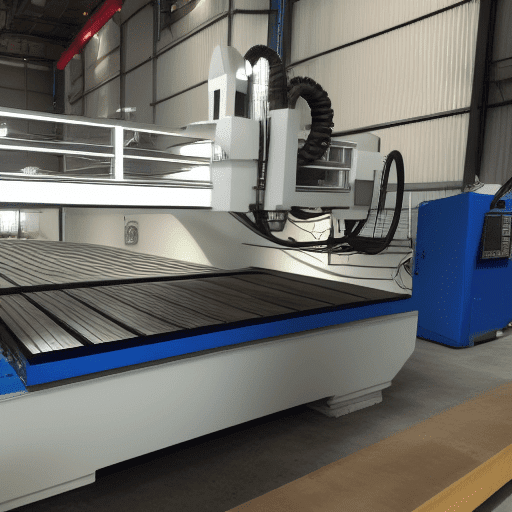

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to shape and form the material into a variety of different shapes and sizes. Milling machines can be used to perform a variety of operations, including drilling, boring, reaming, tapping, and countersinking. They can also be used to create complex shapes and contours, as well as to cut slots and keyways. Milling machines are used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing. They are also used in the production of precision parts, such as gears, bearings, and other components. Milling machines are available in both manual and CNC (computer numerical control) versions, and can be used to produce a wide range of products.

What are the types of milling machine?

Milling machines are tools used in the metalworking industry for shaping and cutting metal and other materials. There are several different types of milling machines, each with its own set of features and capabilities. The most common types of milling machines are vertical milling machines, horizontal milling machines, and combination milling machines.

Vertical milling machines are the most common type of milling machine and are used for a variety of operations. They are designed to cut material along the vertical axis, and are typically used for drilling, boring, and cutting operations. Vertical milling machines are available in a variety of sizes and can be used for a variety of operations, including drilling, boring, and cutting.

Horizontal milling machines are designed to cut material along the horizontal axis. They are typically used for drilling, boring, and cutting operations. Horizontal milling machines are available in a variety of sizes and can be used for a variety of operations, including drilling, boring, and cutting.

What is CNC milling process?

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a workpiece in order to create a custom-designed part or product. The process begins with a CAD (Computer Aided Design) drawing of the part or product that is to be created. This drawing is then converted into a set of instructions for the CNC machine, which is programmed to move the cutting tool in a specific pattern and at a specific speed to create the desired shape.

The CNC milling process is typically used to create complex parts with tight tolerances and intricate features. It is also used to create parts with a variety of shapes, including flat surfaces, curved surfaces, and complex 3D shapes. The CNC milling process is highly accurate and can produce parts with a high degree of precision.

Is lathe the same as milling machine?

No, lathe and milling machine are two distinct types of machine tools. A lathe is a machine that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, or deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. A milling machine, on the other hand, is a machine tool used to machine solid materials such as metal and wood. It uses rotary cutters to remove material from a workpiece by advancing or feeding in a direction at an angle with the axis of the tool. It can also be used to shape and finish the material. The milling machine is used to cut and shape materials such as metal, wood, and plastic. It can also be used to create complex shapes and contours. The main difference between a lathe and a milling machine is the way in which they cut materials.

What is the difference between machining center and CNC?

The primary difference between a machining center and a CNC (Computer Numerical Control) machine is the level of automation. A machining center is a type of machine tool that uses a rotating cutting tool to remove material from a workpiece. It is typically used to produce parts with complex geometries and high precision. A CNC machine, on the other hand, is a computer-controlled machine tool that uses a computer program to control the motion of the cutting tool. CNC machines are more automated than machining centers, as they can be programmed to perform a variety of tasks with minimal human intervention.

In terms of operation, machining centers are typically manually operated, while CNC machines are automated. Machining centers are typically used for operations such as drilling, tapping, reaming, and milling, while CNC machines are used for more complex operations such as contouring, profiling, and 3D machining.

What is the process of milling?

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. It is commonly used to create parts with complex shapes and features, such as slots, grooves, and contours. The process of milling begins with the selection of the appropriate cutting tool for the job. This tool is typically a multi-point cutting tool, such as an end mill or a drill bit. The cutting tool is then mounted in a milling machine, which is a machine that holds and rotates the cutting tool.

Once the cutting tool is mounted, the workpiece is then placed in the milling machine and secured in place. The cutting tool is then moved in a specific direction and at a specific speed to begin the cutting process. The cutting tool is typically moved in a linear direction, but can also be moved in a circular pattern. As the cutting tool moves, it removes material from the workpiece in the form of chips. The chips are then collected and disposed of.

What are the types of milling machine?

Milling machines are tools used in the metalworking industry for shaping solid materials like metal, wood, plastics, and other materials. There are several different types of milling machines, each with its own set of features and capabilities.

The most common type of milling machine is the vertical milling machine. This type of machine has a spindle that moves up and down, allowing the user to shape the material by cutting away at it from different angles. Vertical milling machines are typically used for more complex operations, such as creating slots, grooves, and other features.

Another type of milling machine is the horizontal milling machine. This type of machine has a spindle that moves side to side, allowing the user to shape the material by cutting away at it from different angles. Horizontal milling machines are typically used for simpler operations, such as cutting straight lines or creating flat surfaces.

What industries use milling machines?

Milling machines are used in a variety of industries for a variety of purposes. They are most commonly used in the manufacturing industry for machining parts and components to precise specifications. They are also used in the automotive, aerospace, and construction industries for cutting and shaping materials. Milling machines are also used in the medical industry for creating prosthetics and implants, as well as in the food industry for grinding and milling grains and other food products. Additionally, milling machines are used in the woodworking industry for cutting and shaping wood, and in the jewelry industry for creating intricate designs. Finally, milling machines are used in the mining industry for drilling and cutting into rock and other materials.

What products are made using a milling machine?

A milling machine is a versatile tool used in a variety of industrial applications, from shaping and cutting metal to creating intricate patterns and designs. It is used to shape and cut materials such as wood, metal, plastic, and foam. It can also be used to create complex shapes and patterns, as well as to drill and bore holes. Common products made using a milling machine include:

– Automotive parts such as engine blocks, cylinder heads, and camshafts

– Aerospace components such as turbine blades and landing gear

– Medical equipment such as prosthetic implants and orthopedic implants

– Electronics components such as circuit boards and connectors

– Musical instruments such as guitars and drums

– Woodworking products such as furniture and cabinetry

– Metalworking products such as tools and dies

– Plastic products such as toys and packaging

– Jewelry such as rings and pendants

– Food products such as pasta and candy

– Textiles such as fabrics and carpets

– Printing products such as labels and signs