Advanced CNC programming secrets involve optimizing G-code, implementing parametric programming, and utilizing macro capabilities. Skilled programmers leverage subprograms and custom cycles to enhance efficiency and reduce code complexity. They employ advanced toolpath strategies, such as trochoidal milling and high-speed machining techniques, to improve cutting performance and tool life. Mastering cutter compensation, work coordinate systems, and probing routines allows for greater precision and adaptability in machining processes.

Experienced CNC programmers also integrate CAM software effectively, fine-tuning post-processors and utilizing simulation tools to verify and optimize their code before running it on the machine. Additionally, they implement adaptive feed rate control and real-time tool monitoring to maximize productivity and minimize errors.

These advanced techniques, combined with a deep understanding of machine kinematics and material properties, enable programmers to push the boundaries of CNC machining capabilities, resulting in faster production times, improved part quality, and reduced manufacturing costs.

- Discover advanced CNC programming techniques to take your skills to the next level.

- Learn how to optimize settings and improve productivity in CNC programming.

- Gain practical knowledge that can be immediately applied in the CNC programming world.

- Enhance your understanding of CNC milling and turning operations.

- Explore specialized programming features like tool offsets, program formatting, and canned cycles.

Overview of CNC Programming-Secrets Revealed

CNC Programming-Secrets Revealed is a comprehensive CD course that delves into various programming topics to enhance your CNC programming skills and boost productivity. This course covers both CNC milling and turning operations, providing step-by-step instructions to guide you through the machining processes. Whether you are a machinist, programmer, engineer, or supervisor, this course is designed to cater to your needs.

Featuring an introductory chapter on CAD/CAM and an overview of MasterCAM, this course lays a solid foundation for your understanding of CNC programming. With a plethora of programming projects, exercises, solutions, and reference files, you can practice and implement your newfound knowledge into real-world scenarios.

The course encompasses practical information and hands-on projects that aim to refine your programming skills, optimize settings, and maximize efficiency. By following the provided exercises and referencing the comprehensive solutions, you’ll gain a deeper understanding of programming techniques and concepts.

CNC Programming-Secrets Revealed caters to CNC programmers at all skill levels. Whether you’re a beginner looking to establish a solid programming foundation or an experienced programmer seeking to enhance your skills, this course has something valuable to offer. It equips you with the necessary tools and knowledge to navigate the complex CNC programming world with ease.

Continually honing your CNC programming skills is essential in today’s competitive manufacturing industry. With CNC Programming-Secrets Revealed, you’ll have access to a wealth of programming projects, exercises, solutions, and reference files that provide practical value and help you stay ahead of the curve.

Features of CNC Programming-Secrets Revealed

CNC Programming-Secrets Revealed is an invaluable resource for CNC programmers looking to enhance their skills and unlock advanced CNC programming techniques. This comprehensive course covers a wide range of topics, from the basics of CNC programming to advanced concepts.

One of the standout features of CNC Programming-Secrets Revealed is its extensive collection of illustrations, tables, and formulas. These visual aids help to clarify complex programming concepts and make it easier for learners to grasp and apply the material. The course also includes practical tips, shortcuts, and real-world examples to provide a hands-on learning experience.

The course is carefully organized and structured, allowing users to quickly find the information they need. Whether you’re a beginner or an experienced programmer, CNC Programming-Secrets Revealed offers a valuable reference guide that covers all the essential areas of CNC programming.

To give you a glimpse of what you can expect, here are just a few examples of the resources and features available in CNC Programming-Secrets Revealed:

Illustrations:

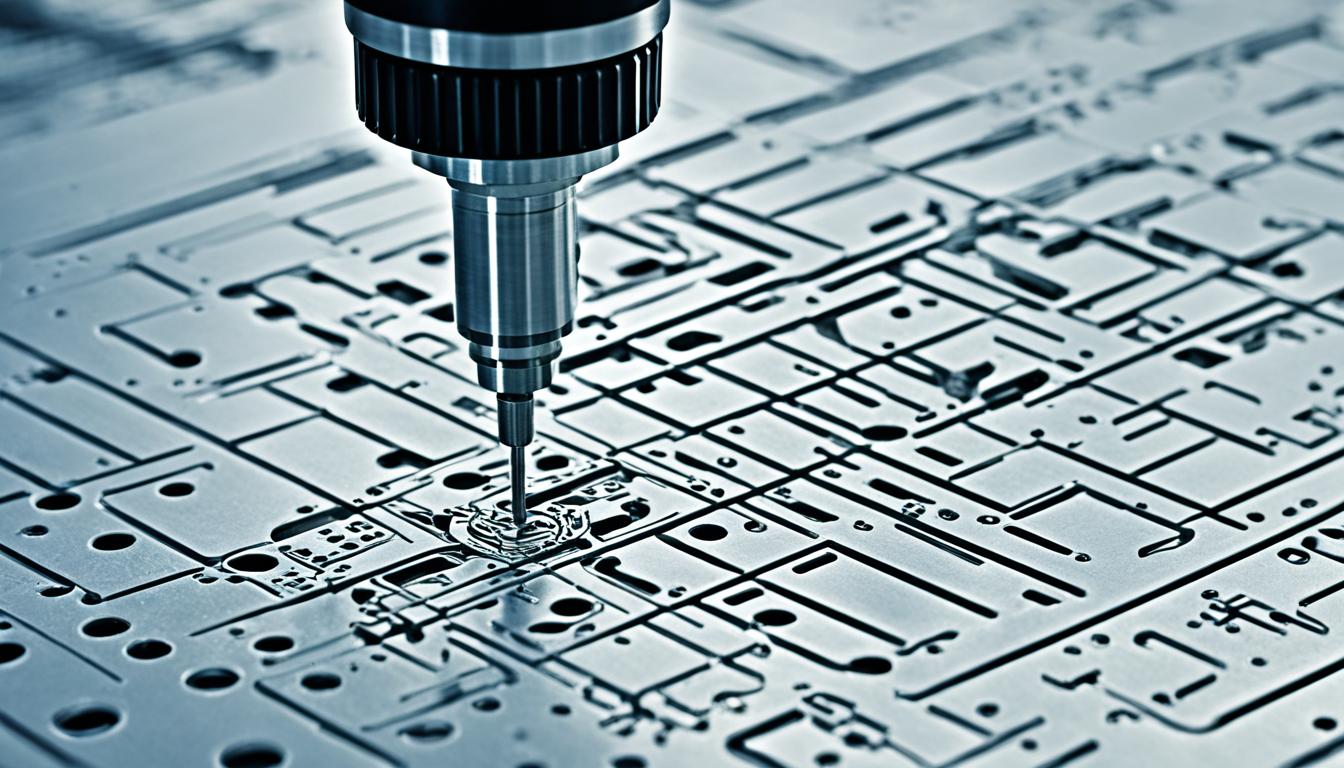

- Visual representations of machining processes

- Detailed diagrams of tool paths and tool movements

- Step-by-step illustrations of programming techniques

Tables and Formulas:

- Speed and feed tables for different materials

- Formulas for calculating tool offsets and dimensions

- Reference tables for common programming codes

Tips and Shortcuts:

- Time-saving techniques for optimizing CNC programs

- Shortcuts for avoiding common programming mistakes

- Best practices for efficient programming and setup

Real-World Examples:

- Case studies showcasing programming solutions for specific applications

- Examples of programming challenges and their resolutions

- Sample programs with detailed explanations

With its wealth of features and resources, CNC Programming-Secrets Revealed is the ultimate guide for CNC programmers looking to take their skills to the next level. Whether you’re a beginner seeking to understand the basics or an experienced programmer looking for advanced techniques, this course has everything you need to excel in the world of CNC programming.

What is CNC Programming and how can it help you?

CNC Programming is the art of programming CNC machines to make parts. It is a vital skill for machinists and programmers in the manufacturing industry. By understanding CNC programming, individuals can unleash the full potential of CNC machines and achieve precise and efficient results.

At its core, CNC programming involves writing instructions that control the movements and actions of CNC machines. These instructions are written in a language called g-code, which is the standard language used in CNC programming. G-code consists of commands that tell the machine how to move, where to position the tool, and what actions to perform.

CNC programming can be done using different methods, such as CAM programming, conversational programming, or direct g-code programming. CAM software, such as MasterCAM, is commonly used to convert CAD models into g-code instructions. This allows programmers to visualize the part and generate tool paths automatically.

Conversational programming is another approach where programmers can input parameters and answers to a series of questions posed by the machine control software. This method is simpler and more intuitive, making it accessible to users with limited programming skills.

On the other hand, direct g-code programming involves manually writing the g-code instructions to control the CNC machine. This method requires a deep understanding of the g-code language and offers the most flexibility to programmers.

Learning CNC programming opens up a world of opportunities for individuals in the manufacturing industry. It allows them to create complex parts with precision and efficiency, reducing errors and waste. CNC programming skills are highly valued in the job market, and professionals with these skills often command higher salaries and have more career advancement opportunities.

The Benefits of Learning CNC Programming

- Enhanced machining skills: Understanding CNC programming enables individuals to take full advantage of the capabilities of CNC machines, allowing for more accurate and efficient machining operations.

- Higher-paying careers: CNC programming skills are in high demand, and professionals with these skills often earn higher salaries compared to those without them.

- Reduced errors and waste: By programming CNC machines accurately, individuals can minimize errors and material wastage, resulting in cost savings for companies.

- Greater career opportunities: CNC programming opens up a range of career opportunities in industries such as aerospace, automotive, and manufacturing.

Whether you’re a machinist, programmer, engineer, or supervisor, learning CNC programming is a valuable investment in your skills and professional growth. It allows you to harness the power of CNC machines and achieve exceptional results in the manufacturing process.

| Career | Average Salary (per year) |

|---|---|

| CNC Machine Operator | $42,000 |

| CNC Machinist | $42,000 |

| CNC Programmer | $54,000 |

The Importance of Learning G-Code

Learning G-code, the language used to control CNC machines, is crucial for CNC machinists. G-code programming skills can set you apart in the job market and lead to higher-paying positions. According to Glass Door, CNC Programmers earn an average salary of $54,000 per year, compared to CNC Machine Operators and CNC Machinists who earn $42,000 per year. Learning G-code allows CNC machinists to become more versatile and capable of tackling complex projects. It also opens up opportunities for advancement and career growth.

By mastering G-code, CNC machinists gain the ability to create precise and efficient tool paths, dictate machine movements, and execute intricate machining operations. This expertise enhances their value to employers, who seek skilled professionals capable of maximizing production efficiency and minimizing errors.

Moreover, learning G-code enables CNC machinists to understand and troubleshoot programs effectively. By being able to read, interpret, and modify G-code instructions, they can optimize machining processes, implement improvements, and ensure the successful execution of manufacturing tasks.

As shown in the table, CNC Programmers earn significantly higher salaries than CNC Machine Operators and CNC Machinists. This disparity is a result of the specialized skills and knowledge required to excel in CNC programming, particularly in G-code programming.

Learning G-code is an investment in your career as a CNC machinist. It equips you with the technical expertise to tackle complex machining projects, enhances your value in the job market, and increases your earning potential.

The Different Methods of CNC Programming

When it comes to programming CNC machines, there are three main methods: CAM software, conversational programming, and g-code programming. Each method has its own unique advantages and can be used in combination to optimize programming efficiency.

CAM Software

CAM software, or Computer-Aided Manufacturing software, is a powerful tool used to convert CAD models into g-code instructions. It provides a user-friendly interface that simplifies the programming process by generating tool paths automatically. With CAM software, programmers can easily visualize and manipulate the design, making it an ideal choice for complex machining projects.

Conversational Programming

Conversational programming is a more intuitive approach to CNC programming. It involves a series of questions and inputs from the user, which are used to generate the g-code. This method eliminates the need for manual programming and makes it easier for operators with limited programming knowledge to create accurate and efficient programs quickly. Conversational programming is particularly beneficial for simple machining operations or when programming on the shop floor.

G-code Programming

G-code programming is the most flexible method of CNC programming. It involves directly writing the g-code instructions to control the machine. This method offers complete control over the programming process and allows for customization and optimization of programs. G-code programming requires a deeper understanding of the g-code language and is commonly used by experienced programmers for complex and specialized machining operations.

By combining these methods, programmers can leverage the strengths of each approach and achieve optimal results. For example, a programmer might use CAM software to generate the basic tool paths and then switch to g-code programming to fine-tune the program for specific requirements.

| CNC Programming Method | Advantages |

|---|---|

| CAM Software | – Powerful and visually intuitive\n- Simplifies complex programming tasks\n- Automatic generation of tool paths |

| Conversational Programming | – Faster and more intuitive programming\n- Ideal for simple machining operations\n- Requires less programming knowledge |

| G-code Programming | – Complete control over programming\n- Flexibility for customization and optimization\n- Suitable for complex and specialized operations |

The Best Way to Learn G-Code

Learning G-code, the language used to control CNC machines, is essential for aspiring CNC programmers. To truly master G-code, a comprehensive course that covers the fundamentals and provides hands-on exercises is the best approach. By immersing yourself in a structured learning environment, you can gain a solid understanding of G-code syntax, commands, and techniques that form the foundation of CNC programming.

One powerful tool that can greatly enhance the learning experience is a simulator like G-Wizard Editor. This software allows you to visualize and experiment with different G-code commands in a virtual environment. By simulating CNC machine behavior, you can test and refine your programs without the risk of damaging physical equipment. This hands-on practice is invaluable for honing your programming skills and building confidence in working with G-code.

An effective strategy for learning G-code is to take a “top-down” approach. Start with a desired shape or part, and then break it down into the necessary arcs, circles, and lines. By understanding how different geometric elements are represented in G-code, you can gradually build your knowledge and proficiency. This approach makes learning G-code more intuitive and enables you to create complex programs for intricate machining operations.

Additionally, it is beneficial to stay up to date with the latest trends and techniques in CNC programming. Following articles and blogs about CNC programming can provide additional insights, tips, and real-world examples. This continuous learning process helps you stay informed of advancements in the field and exposes you to different perspectives and problem-solving approaches.

Remember, learning G-code is a journey that requires patience, practice, and perseverance. By investing time and effort into mastering this fundamental skill, you can unlock the full potential of CNC programming and open up exciting opportunities in the world of machining.

Exploring G-Code Standards and Dialects

G-code, the programming language used to control CNC machines, operates with specific standards and dialects that vary depending on the machine and manufacturer. Understanding these standards and dialects is crucial for efficient CNC programming and ensuring compatibility across different machines.

Each CNC machine may utilize different sets of G-code commands and syntax. To ensure accurate programming, it is essential to consult the machine’s manual and documentation for the specific G-codes and their meanings. By familiarizing oneself with the machine’s G-code standards and dialects, programmers can write code that is both compatible and efficient, resulting in optimized machining operations.

An in-depth understanding of G-code standards and dialects also allows programmers to adapt and work with machines that have proprietary formats. This knowledge enables them to overcome any challenges posed by variations in G-code implementation and efficiently utilize the machine’s capabilities.

Considerations for Working with G-Code Standards and Dialects:

- Consult the machine’s manual and documentation for specific G-codes and their meanings.

- Be aware of proprietary formats used by certain machines.

- Ensure compatibility and efficiency in CNC programming by adhering to the machine’s G-code standards.

- Adapt programming practices to accommodate variations in G-code dialects.

Taking the time to understand G-code standards and dialects enhances a programmer’s ability to write effective programs for different machines and achieve optimal results during CNC operations.

Enhancing CNC Programming with Software

CNC programming can be taken to the next level with the use of specialized software tools. These software solutions provide advanced features and functionalities that enhance productivity, efficiency, and precision in CNC programming.

CAM Software

CAM software plays a critical role in CNC programming by converting CAD models into g-code instructions. It offers powerful tools for generating tool paths, optimizing cutting strategies, and simulating machining operations. With CAM software, programmers can efficiently create complex machining programs and visualize the entire process before sending it to the CNC machine.

Conversational Programming Software

Conversational programming software simplifies the programming process by presenting a series of questions and options to generate g-code. This approach eliminates the need for manual coding and enables programmers to quickly create CNC programs without in-depth knowledge of g-code programming. Conversational programming software is particularly useful for beginners or users who prefer a more intuitive programming experience.

G-code Editing Software

G-code editing software provides more manual control and allows programmers to directly edit and optimize g-code programs. It offers functionalities such as syntax highlighting, code analysis, and debugging tools, enabling programmers to fine-tune their programs for optimal performance. G-code editing software is ideal for experienced CNC programmers who require precise control over their machining operations.

By utilizing a combination of these software tools – CAM software, conversational programming software, and g-code editing software – CNC programmers can maximize their efficiency, streamline their workflow, and adapt to different programming requirements. These software solutions empower programmers to create sophisticated CNC programs with ease, resulting in improved machining accuracy and productivity.

Unlocking Advanced CNC Programming Secrets

Advanced CNC programming techniques are the key to taking your programming skills to the next level. One such technique is macro B programming, which empowers programmers to create custom functions and automate repetitive tasks, leading to improved programming efficiency and reduced errors. However, mastering these advanced techniques requires consistent practice and experimentation.

One effective way to enhance your understanding of advanced CNC programming is by studying and analyzing existing G-code examples. By examining different programming approaches and solutions, you can gain valuable insights that will sharpen your own programming skills. This process of continuous learning and expanding your programming knowledge is crucial to unlocking the secrets of advanced CNC programming.

With the right combination of dedication and practice, CNC programmers can achieve exceptional results. By harnessing the power of advanced CNC programming techniques like macro B programming and leveraging the insights gained from studying G-code examples, you can elevate your programming skills and bring a new level of efficiency and accuracy to your CNC machining operations.