The future of CNC machining is one of continued growth and expansion. As technology advances and new manufacturing techniques are developed, CNC machining will become ever more precise and efficient, leading to even greater demand for CNC machining services. In the coming years, CNC machining will become increasingly automated. Automated CNC machining systems will take over much of the labor and skill required to create complex parts and components. Automated CNC machining systems will be able to make parts and components with greater precision and accuracy than ever before, leading to less waste and greater efficiency. The materials used in CNC machining will also become more varied and diverse. New materials, such as titanium and composite materials, will provide manufacturers with the ability to create more complex parts and components with greater strength and durability. New technology, such as 3D printing, will also allow manufacturers to create parts and components with intricate designs and shapes.

As the technology of CNC machining continues to evolve, the cost of CNC machining services will continue to decrease. This will make CNC machining services more affordable and accessible to a wider range of customers. Additionally, the increased efficiency of CNC machining services will lead to faster production times and shorter lead times, allowing customers to receive their parts and components more quickly. Overall, the future of CNC machining looks bright. As technology advances and new materials and techniques are developed, CNC machining will become ever more accurate and efficient. This will lead to increased demand for CNC machining services, as well as greater affordability and accessibility. In the coming years, CNC machining will become an even more integral part of the manufacturing industry.

How CNC Machining Will Advance Manufacturing in the Future

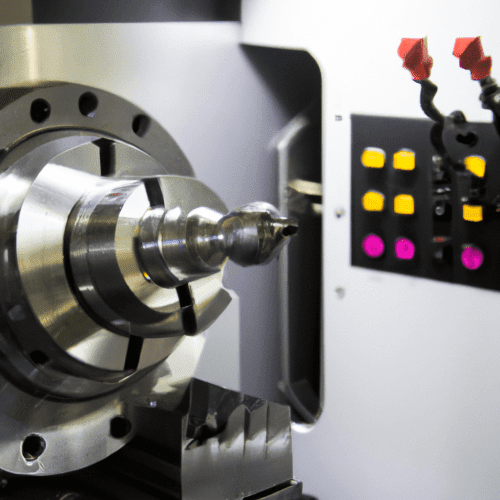

CNC machining is an advanced manufacturing process that has revolutionized the field of manufacturing. This method of machining is based on computer numerical control (CNC) technology, which enables machines to be operated by a computer program. The CNC machining process is used to create precision parts and components of all shapes and sizes, from simple parts to complex components. CNC machining offers a number of advantages over traditional machining methods. It is faster, more accurate, and more cost effective than manual machining. CNC machines also offer a higher level of precision and can produce complex parts with greater accuracy. Furthermore, CNC machining eliminates the need for manual labor, reducing the labor costs associated with traditional machining processes. The future of CNC machining looks very promising. As technology continues to improve, CNC machining will become even more accurate and efficient.

Newer CNC machines are capable of producing complex parts with a greater degree of accuracy and precision than ever before. In addition, CNC machining is becoming increasingly affordable, making it accessible to more businesses. The increased accuracy and efficiency of CNC machining will have a positive impact on the manufacturing industry. CNC machining will reduce the time it takes to produce parts and components, resulting in increased productivity and decreased production costs. Furthermore, CNC machining will allow businesses to produce more complex parts with greater accuracy and precision, leading to improved product quality. CNC machining will also have a positive effect on the environment. By reducing the amount of manual labor involved in the manufacturing process, CNC machining will reduce the amount of energy required to produce parts and components, which will lead to a decrease in energy consumption and air pollution. In conclusion, CNC machining will be an integral part of the manufacturing industry in the future. This advanced manufacturing process offers numerous benefits, from increased accuracy and precision to reduced labor costs. As technology continues to improve, CNC machining will become even more efficient and accurate, resulting in improved product quality and reduced environmental impacts.

The Benefits of Automation in CNC Machining

Automation is becoming increasingly important in industries that rely on CNC (Computer Numerical Control) machining. CNC machining is a process used to control the cutting of materials such as metal and plastic with the use of a computer. Automation is the use of technology to automate tasks that would otherwise be done manually. Automation in CNC machining can lead to a number of benefits, including improved accuracy, increased productivity, and cost savings. First and foremost, automation in CNC machining can help to improve the accuracy of the machining process. Automation allows the machine to be programmed with a precise set of instructions, which eliminates human error. This ensures that the machined parts meet the exact specifications of the customer. Automation also allows for the use of advanced sensing technology, such as probes and lasers, which can detect even the slightest deviations from the desired specifications.

Automation also increases productivity in CNC machining. Automated machines can run for longer periods of time with fewer interruptions and can produce more parts in a shorter amount of time. This can help to reduce the cost of production, as it eliminates the need for additional labor and allows the company to produce more parts in a shorter amount of time. Finally, automation in CNC machining can lead to cost savings. Automated machines require less maintenance, as they can be programmed to perform routine maintenance tasks. This can reduce the need for manual labor, which can help to reduce the cost of production. Additionally, automated machines can be programmed to run 24 hours a day, which eliminates the need for overtime pay. In conclusion, automation in CNC machining can lead to a number of benefits, including improved accuracy, increased productivity, and cost savings. Automation can help to ensure that parts meet customer specifications, increase the rate of production, and reduce the need for manual labor. Automation in CNC machining is becoming increasingly important in a wide variety of industries.

Exploring the Possibilities of AI and Big Data in CNC Machining

The use of Artificial Intelligence (AI) and Big Data in CNC (Computer Numerical Control) machining is becoming increasingly popular. AI and Big Data have the potential to revolutionize the way CNC machining is done. AI can be used to automate processes and improve the efficiency of CNC machining. AI can be used to analyze and interpret data from previous machining jobs and provide recommendations for how to increase productivity. AI can also be used to create virtual models of machining processes to help optimize them for better results. AI can even be used to detect and diagnose potential problems with a CNC machine before they arise, preventing costly downtime and repairs. Big Data can also play an important role in CNC machining. By collecting and analyzing data from previous machining jobs, Big Data can help identify trends and patterns that can be used to improve the overall efficiency of the process.

Big Data can also be used to detect and predict potential problems with a CNC machine before they become an issue. This helps to reduce downtime and increase productivity. By combining the power of AI and Big Data, CNC machining can become more efficient and cost-effective. Through the use of AI and Big Data, CNC machining can become smarter, faster and more accurate. AI and Big Data can also help to improve the quality and consistency of CNC machined parts. The potential of AI and Big Data in CNC machining is enormous. By utilizing their potential, CNC machining can become more efficient and cost-effective. The use of AI and Big Data in CNC machining is a trend that is sure to continue growing in the near future.

The Benefits of 3D Printing in CNC Machining

3D printing is an exciting and innovative technology that is quickly being adopted in the CNC machining sector. By combining the precision and accuracy of CNC machining with the versatility of 3D printing, manufacturers can create complex parts with intricate detail that would otherwise be impossible to create with traditional machining methods. One of the greatest advantages of 3D printing in CNC machining is its ability to produce complex parts in a much shorter amount of time than traditional machining methods. Unlike traditional machining, 3D printing does not require the cutting of large metal blocks and the time consuming process of making each individual part. Instead, 3D printing utilizes a process of “layering” and “stacking” to create complex parts in a fraction of the time. This is particularly useful for CNC machining, as it allows manufacturers to quickly produce a variety of parts without having to set up and maintain multiple machines. In addition to its speed, 3D printing also allows for greater accuracy and precision than traditional machining methods.

By using a 3D printer, manufacturers can create parts with highly intricate details that are impossible to replicate with traditional machining. This means that parts created with 3D printing can be customized to meet the exact specifications of a customer, providing them with a perfect end product. Finally, 3D printing in CNC machining also provides cost savings over traditional machining methods. Because 3D printing does not require the purchase and maintenance of multiple machines, manufacturers can save money on overhead costs. Additionally, the cost of materials used in 3D printing is typically much lower than those used in traditional machining, resulting in further savings for manufacturers. Overall, 3D printing in CNC machining provides numerous benefits to manufacturers, including increased speed, accuracy, precision, and cost savings. By combining the power of CNC machining with the versatility of 3D printing, manufacturers can create complex parts with intricate detail in a fraction of the time with minimal overhead costs.

How CNC Machining Could Revolutionize the Automotive Industry

The automotive industry has long been one of the most important sectors of the global economy. In recent years, the industry has been revolutionized by the advent of new technologies, such as computer numerical control (CNC) machining. CNC machining has enabled automotive manufacturers to produce parts with a higher degree of precision, accuracy, and repeatability than ever before. CNC machining involves the use of computer-controlled machinery to shape and cut materials into a desired shape. This type of machining allows for a high degree of control, accuracy, and repeatability, resulting in parts that are more precise than those produced using traditional manufacturing methods. CNC machining can also be used to produce parts in shorter lead times, which is a great benefit in the automotive industry where time-to-market is of utmost importance.

CNC machining has changed the way automotive parts are produced. This technology has enabled manufacturers to produce parts with greater precision and accuracy than ever before. It has also allowed for shorter lead times in production, which helps automotive companies to get their products to market faster. CNC machining has revolutionized the automotive industry by allowing for the production of more complex shapes and features with higher precision and accuracy than ever before. This technology has also enabled manufacturers to reduce lead times, resulting in faster time-to-market for new car models. The automotive industry has seen tremendous growth in recent years, and CNC machining has played an important role in that growth.

This technology has allowed for the production of more precise and accurate parts, allowing automotive manufacturers to produce higher quality cars with shorter lead times. This has enabled automotive companies to remain competitive in a global market and to meet the needs of their customers. In the future, CNC machining will continue to revolutionize the automotive industry, enabling manufacturers to produce more advanced and efficient cars.