CNC turning is a machining process that uses computer numerical control (CNC) to automate the production of parts. It is a popular choice for many manufacturing operations due to its ability to produce high-precision parts with a high degree of repeatability. CNC turning has several advantages and disadvantages that should be considered when deciding whether or not to use it for a particular application.

Advantages of CNC Turning

One of the primary advantages of CNC turning is its ability to produce parts with a high degree of accuracy and repeatability. CNC turning machines are programmed with precise instructions that allow them to produce parts with tight tolerances and repeatable results. This makes CNC turning ideal for producing parts with complex geometries and tight tolerances. Additionally, CNC turning machines are capable of producing parts with a high degree of surface finish, which is important for many applications.

CNC turning is also a cost-effective machining process. CNC turning machines are relatively inexpensive to purchase and maintain, and they can produce parts quickly and efficiently. This makes CNC turning a great choice for high-volume production runs. Additionally, CNC turning machines are relatively easy to program, which can reduce setup times and lead to faster production cycles.

Disadvantages of CNC Turning

One of the primary disadvantages of CNC turning is that it is limited to producing parts with rotational symmetry. This means that CNC turning is not suitable for producing parts with complex geometries or features that require multiple axes of motion. Additionally, CNC turning machines are limited in terms of the materials they can work with. CNC turning machines are typically limited to working with softer materials such as aluminum, brass, and plastic.

CNC turning is also a relatively slow process compared to other machining processes. CNC turning machines are limited in terms of the speed at which they can move, which can lead to longer production times. Additionally, CNC turning machines require frequent maintenance and calibration in order to maintain accuracy and repeatability. This can lead to additional downtime and increased costs.

What are the 3 advantages of CNC machining?

CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape and cut materials into a desired shape or size. CNC machining is a popular choice for many industries due to its numerous advantages. Here are three of the main advantages of CNC machining:

1. Precision: CNC machining is highly accurate and precise, allowing for the production of complex parts with tight tolerances. This is especially beneficial for industries that require parts with exact specifications, such as the aerospace and medical industries.

2. Efficiency: CNC machining is a highly efficient process, as it eliminates the need for manual labor and reduces the amount of time needed to produce parts. This allows for faster production times and lower costs.

3. Versatility: CNC machining is a versatile process that can be used to produce a wide variety of parts. This includes parts made from a variety of materials, such as metals, plastics, and composites. CNC machining can also be used to produce parts with complex shapes and intricate details.

What is the biggest disadvantage of using CNC?

The biggest disadvantage of using CNC (Computer Numerical Control) is the cost. CNC machines are expensive to purchase and maintain, and require a significant amount of training to operate. Additionally, CNC machines require a large amount of energy to run, which can be costly. Furthermore, CNC machines are limited in their capabilities, as they are programmed to perform specific tasks and cannot be easily adapted to new tasks. Finally, CNC machines are not as accurate as manual machines, and require frequent calibration and maintenance to ensure accuracy.

What is not the advantage of a CNC machine?

One of the main advantages of a CNC machine is its ability to produce parts with high accuracy and repeatability. However, this is not the only advantage of a CNC machine. Other advantages include its ability to produce complex shapes, its ability to produce parts quickly, its ability to produce parts with a high degree of precision, and its ability to produce parts with a high degree of consistency.

However, one of the disadvantages of a CNC machine is its high cost. CNC machines are typically more expensive than traditional machining methods, such as manual machining. Additionally, CNC machines require a high level of skill and knowledge to operate, and they require regular maintenance and calibration to ensure accuracy and repeatability. Furthermore, CNC machines are limited in the types of materials they can work with, and they are not suitable for all types of machining operations.

What is CNC turning machine?

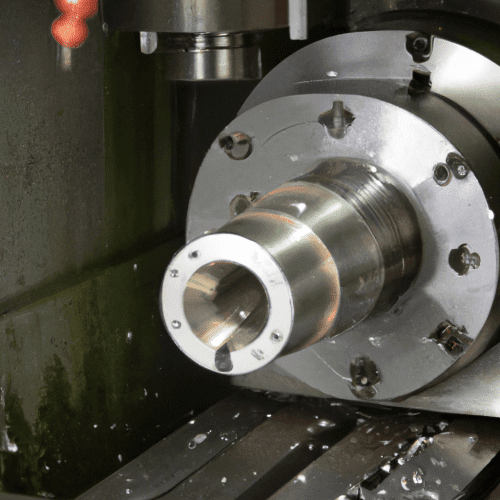

A CNC (Computer Numerical Control) turning machine is a type of automated machine tool that is used to produce precision parts from a variety of materials. It is a type of lathe that uses computer-controlled motors to rotate a workpiece and cut it into a desired shape. The CNC turning machine is capable of producing complex shapes and intricate details with a high degree of accuracy and repeatability. It is used in a variety of industries, including automotive, aerospace, medical, and electronics.

The CNC turning machine consists of a spindle, a tool holder, and a bed. The spindle is the rotating part of the machine that holds the cutting tool. The tool holder is the part that holds the cutting tool in place and is usually mounted on the spindle. The bed is the part of the machine that holds the workpiece in place and is usually made of cast iron or steel.

What are the advantages of lathe machine?

A lathe machine is a versatile tool used in metalworking, woodworking, and other materials. It is used to shape and form materials into a desired shape or size. The advantages of using a lathe machine are numerous.

First, a lathe machine is capable of producing highly accurate and precise parts. This is due to the fact that the cutting tool is held in a fixed position and the material is rotated against it. This allows for a high degree of accuracy and repeatability. Additionally, the cutting tool can be adjusted to produce different shapes and sizes. This makes it possible to produce complex parts with a high degree of accuracy.

Second, a lathe machine is capable of producing parts with a high degree of surface finish. This is due to the fact that the cutting tool is held in a fixed position and the material is rotated against it. This allows for a high degree of accuracy and repeatability. Additionally, the cutting tool can be adjusted to produce different shapes and sizes. This makes it possible to produce complex parts with a high degree of surface finish.