A lathe tool is a cutting instrument used in conjunction with a lathe machine to shape and manipulate various materials, primarily metal, wood, or plastic. These tools come in a wide variety of shapes and sizes, each designed for specific cutting operations such as turning, facing, boring, or threading. Lathe tools typically consist of a cutting edge made from hardened steel, carbide, or other durable materials, mounted on a tool holder that secures it to the lathe’s tool post.

The geometry of the cutting edge, including its rake angle, clearance angle, and nose radius, is carefully engineered to optimize cutting performance and achieve the desired surface finish on the workpiece. Modern lathe tools often feature replaceable inserts, allowing for quick changes and reducing downtime in production environments. The selection of the appropriate lathe tool depends on factors such as the material being machined, the desired finish, and the specific operation being performed, making it an essential component in precision manufacturing and metalworking processes.

Which tool is used for turning operation?

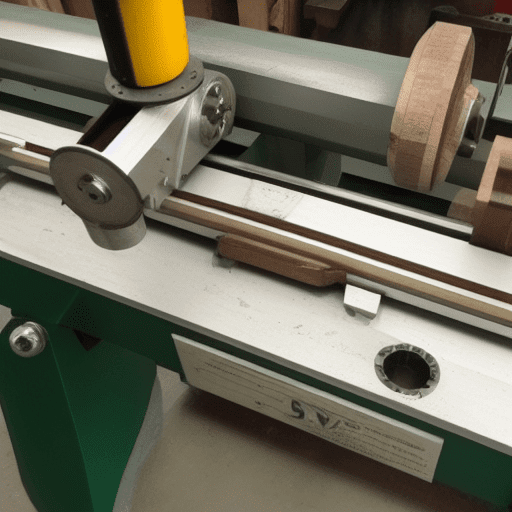

A turning operation is a machining process used to create cylindrical parts by removing material from a workpiece. The workpiece is rotated against a cutting tool, which removes material from the workpiece to create the desired shape. The most common tool used for turning operations is a lathe. A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, or deformation.

The cutting tool is typically a single-point cutting tool, but may also be a multi-point cutting tool. The cutting tool is held in a tool holder and is fed into the rotating workpiece. The cutting tool can be moved linearly along the axis of rotation, or it can be fed at an angle relative to the axis of rotation. The cutting tool can also be moved in a radial direction to create a curved surface. The cutting tool can be made from a variety of materials such as high-speed steel, carbide, or ceramic.

How do you set a lathe tool?

Setting a lathe tool is an important part of machining, as it ensures that the tool is properly aligned and ready to cut. The process of setting a lathe tool involves several steps, including selecting the correct tool, adjusting the tool holder, and setting the cutting edge.

The first step in setting a lathe tool is to select the correct tool for the job. This will depend on the material being machined, the desired finish, and the type of cut being made. Once the correct tool has been selected, it should be placed in the tool holder and secured with the appropriate screws.

The next step is to adjust the tool holder. This involves adjusting the height of the tool holder so that the cutting edge of the tool is at the correct height for the job. The tool holder should also be adjusted so that the cutting edge is perpendicular to the workpiece.

The final step in setting a lathe tool is to set the cutting edge. This involves adjusting the angle of the cutting edge so that it is at the correct angle for the job.

What is a lathe bit?

A lathe bit is a cutting tool used in a lathe machine to shape and form materials such as wood, metal, and plastic. It is typically made of high-speed steel and is held in place by a tool holder. The cutting edge of the bit is usually shaped like a cone, cylinder, or a V-shape. The shape of the bit determines the type of cut it will make. For example, a V-shaped bit is used for cutting grooves, while a cone-shaped bit is used for making round shapes. The cutting edge of the bit is also sharpened to a specific angle to ensure a clean cut. The angle of the cutting edge is determined by the type of material being cut and the desired finish. Lathe bits come in a variety of sizes and shapes to accommodate different types of materials and cutting applications.