CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape and cut materials into a desired shape or size. CNC machining is a subtractive manufacturing process, meaning that material is removed from a workpiece to create the desired shape or size. CNC machining is used to create parts for a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC machining works by using a computer program to control the movement of the machine’s cutting tools. The program is written in a language called G-code, which is a numerical code that tells the machine what to do. The program is loaded into the machine’s memory and the machine is then ready to begin machining.

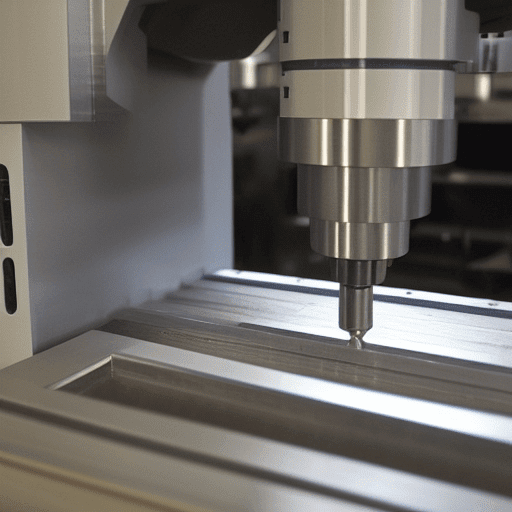

The CNC machine is equipped with a variety of cutting tools, such as drills, end mills, and reamers. The cutting tools are mounted on a spindle, which is driven by a motor. The spindle is connected to a computer-controlled servo motor, which is used to move the cutting tool in three dimensions. The servo motor is programmed to move the cutting tool in a specific pattern, which is determined by the G-code program.

The cutting tool is then used to cut away material from the workpiece. The cutting tool is moved in a specific pattern, which is determined by the G-code program. The cutting tool is moved in a series of linear and circular motions, which are determined by the G-code program. The cutting tool is moved in a precise manner, which allows for the creation of complex shapes and sizes.

Once the cutting is complete, the workpiece is removed from the machine and inspected for accuracy. If the workpiece meets the desired specifications, it is ready for use. If not, the CNC machine can be adjusted and the process repeated until the desired results are achieved.

What is CNC material?

CNC material is a type of material that is used in Computer Numerical Control (CNC) machining. CNC machining is a manufacturing process that uses computer-controlled machines to shape and cut materials into a desired shape or size. CNC material is typically a metal, such as aluminum, steel, brass, or titanium, but can also be a plastic or composite material. The material is fed into the CNC machine, which then uses a variety of tools to cut, shape, and finish the material into the desired shape or size. CNC machining is used in a variety of industries, including automotive, aerospace, medical, and consumer products.

CNC material is chosen based on the desired application, as different materials have different properties that make them suitable for different applications. For example, aluminum is often used for automotive parts due to its light weight and strength, while titanium is often used for aerospace parts due to its strength and corrosion resistance.

What are the disadvantages of CNC?

CNC (Computer Numerical Control) is a type of automation technology used in the manufacturing industry to control machine tools such as lathes, mills, routers, and grinders. CNC machines are highly accurate and can produce complex parts with a high degree of precision. However, there are some disadvantages associated with CNC machines.

One of the main disadvantages of CNC machines is their high cost. CNC machines are more expensive than traditional machine tools, and the cost of the software and training required to operate them can add to the overall cost. Additionally, CNC machines require regular maintenance and repairs, which can be costly.

Another disadvantage of CNC machines is that they require a high level of skill to operate. CNC machines are programmed using a computer language, and operators must be familiar with the language in order to program the machine correctly. Additionally, CNC machines require a high level of precision, and operators must be able to make adjustments to the machine in order to achieve the desired results.

What is the CNC machine language called?

The CNC machine language is called G-code. G-code is a language that is used to control the movements of a CNC machine. It is a numerical control (NC) programming language that is used to create instructions for the machine to follow. G-code is a language that is used to control the movements of a CNC machine. It is a numerical control (NC) programming language that is used to create instructions for the machine to follow. G-code is a language that is used to control the movements of a CNC machine. It is a numerical control (NC) programming language that is used to create instructions for the machine to follow. G-code is a language that is used to control the movements of a CNC machine. It is a numerical control (NC) programming language that is used to create instructions for the machine to follow. G-code is a language that is used to control the movements of a CNC machine. It is a numerical control (NC) programming language that is used to create instructions for the machine to follow.

How many operations does a CNC machine have?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. CNC machines are used to produce parts with high precision and accuracy, and can be used to perform a variety of operations, including drilling, milling, turning, and grinding. The number of operations a CNC machine can perform depends on the type of machine and the tools it is equipped with.

For example, a CNC milling machine can be used to perform a variety of operations, including drilling, reaming, counterboring, countersinking, and tapping. It can also be used to perform milling operations, such as face milling, shoulder milling, and slotting. A CNC lathe can be used to perform turning operations, such as facing, grooving, and threading. A CNC router can be used to perform routing operations, such as cutting, engraving, and carving.

What is the meaning of M code?

M code, also known as M language, is a programming language developed by Microsoft for use in its Power BI and Power Query products. It is a functional language that is designed to make data transformation and analysis easier and more efficient. M code is a powerful language that allows users to manipulate data in a variety of ways, including combining data from multiple sources, transforming data into different formats, and creating custom calculations. It is also used to create custom visuals and reports.

M code is a powerful language that is easy to learn and use. It is based on the functional programming language F#, and it is designed to be intuitive and easy to read. It is also designed to be extensible, allowing users to create their own custom functions and data transformations.

M code is a powerful tool for data analysis and transformation. It is used to create custom visuals, reports, and calculations, and it can be used to combine data from multiple sources. It is a powerful language that is easy to learn and use, and it is designed to make data analysis and transformation easier and more efficient.