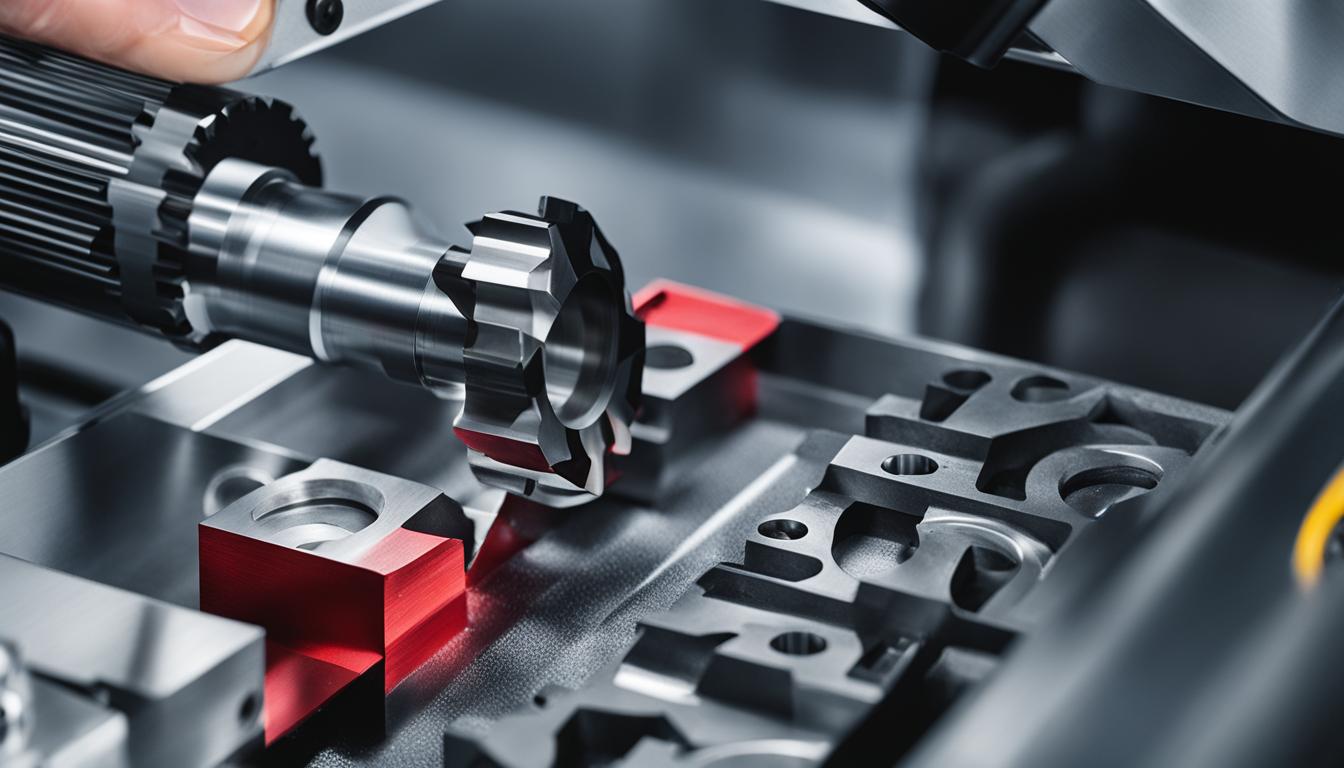

Facing and turning are two fundamental machining processes that play a crucial role in modern manufacturing. These techniques are used to create precise grooves and shapes in workpieces, offering versatility and efficiency for machining enthusiasts.

So, what is facing and turning? Facing is a process that involves cutting a workpiece’s surface to produce a flat, smooth finish. It is commonly used to create precise perpendicular surfaces, clean up rough edges, or prepare the workpiece for further machining. On the other hand, turning is the process of removing material from a rotating workpiece to create cylindrical shapes, such as shafts or rods.

While facing and turning may seem similar, there are key differences between the two. Facing typically involves cutting the outer surface of a workpiece, while turning is usually performed on the inner diameter of a hollow workpiece or the outer diameter of a solid workpiece. Additionally, facing is often done in a radial direction, while turning is done in an axial direction.

Understanding the intricacies of facing and turning is essential for achieving accurate results in machining projects. By mastering these techniques, machining enthusiasts can create precise grooves, achieve the desired shape and finish, and optimize the overall manufacturing process.

Key Takeaways

- Facing and turning are precision-driven machining processes used to create accurate grooves and shapes in workpieces.

- Facing involves cutting a workpiece’s surface to produce a flat, smooth finish, while turning removes material to create cylindrical shapes.

- Facing is typically performed on the outer surface of a workpiece, while turning is done on the inner or outer diameter.

- Mastering facing and turning techniques is crucial for achieving precise results and optimizing the manufacturing process.

Grooving Machining Techniques

Grooving machining encompasses a range of techniques that are essential for creating grooves in workpieces. These techniques include straight turning, face grooving, contour grooving, internal grooving, and external grooving.

Straight Turning

Straight turning is a technique used to create open grooves and turn shafts to a specific diameter. It is commonly used in machining operations where precise control over groove dimensions is crucial.

Face Grooving

Face grooving is ideal for creating axially-aligned grooves on the end face of a part. This technique is often used in applications where grooves need to be perpendicular to the workpiece surface.

Contour Grooving

Contour grooving allows for the creation of grooves with complex geometries. This technique is often employed in applications that require intricate and precise groove shapes, such as in the aerospace and automotive industries.

Internal Grooving

Internal grooving is used to carve out grooves within a hollow workpiece. This technique is commonly used in applications such as creating keyways in shafts or producing internal threads.

External Grooving

External grooving, on the other hand, is used to create grooves on the outer surface of a workpiece. This technique is commonly employed in applications such as producing retaining rings or creating external threads.

These grooving machining techniques offer valuable options for achieving the desired groove shapes and dimensions in various workpieces.

Factors Affecting Grooving Machining

Several factors play a crucial role in the success of grooving machining. Understanding and optimizing these factors are essential for achieving high-quality grooves and maximizing efficiency.

Material Choice

The choice of material has a significant impact on the grooving process. Different materials exhibit varying hardness, chip formation characteristics, and tool wear rates. Selecting the appropriate material is crucial for achieving desired surface finish, minimizing tool wear, and managing chip formation.

Groove Geometry

The geometry of the groove, including its width, depth, and form, determines the setup and parameters of the grooving operation. Accurate measurement and analysis of the desired groove geometry are vital for achieving precise results.

Cutting Parameters

Optimizing cutting parameters is crucial for achieving efficient and high-quality grooving. Depth of cut, feed rate, and cutting speed must be carefully adjusted to maximize productivity and ensure the desired surface finish.

Grooving Tool Selection

Choosing the right grooving tool is critical for achieving accurate and consistent results. The selection of the tool should consider factors such as material compatibility, groove dimensions, and machining requirements. Using the appropriate grooving tool will enhance both the process and the final groove quality.

Chip Management

Effective chip management is essential for smooth and efficient grooving. Proper chip control prevents chip buildup, reduces tool wear, and improves overall machining performance. Chip breakers, coolant/lubricant usage, and appropriate cutting parameters contribute to effective chip management.

Machine Setup

A stable machine setup is essential for consistent and precise grooving. Accurate alignment of the workpiece, tool positioning, and spindle speed optimization all contribute to the success of the grooving process. A well-maintained and calibrated machine ensures reliable and repeatable results.

Example market data:

| Material | Tool Wear | Surface Finish | Chip Formation |

|---|---|---|---|

| Aluminum | Low | Excellent | Long, stringy chips |

| Stainless Steel | High | Poor | Short, breakable chips |

| Brass | Medium | Good | Small granular chips |

Table: Sample market data comparing material characteristics in grooving machining.

Material Considerations in Groove Machining

When it comes to groove machining, different materials require specific considerations to achieve optimal results. Let’s explore some key factors to keep in mind when working with aluminum, stainless steel, and brass.

Aluminum

Aluminum is a commonly used material in various industries due to its lightweight and excellent machinability. When grooving aluminum, it’s essential to take advantage of its characteristics. This means utilizing higher cutting speeds to maintain efficiency. However, aluminum tends to produce long, stringy chips, which can affect chip control during the machining process.

Stainless Steel

Stainless steel is well-known for its durability and corrosion resistance. However, it poses some challenges when it comes to groove machining. This material requires slower cutting speeds to prevent tool overheating and work-hardening, which can negatively impact the final product. Proper chip control is crucial when working with stainless steel to ensure smooth and precise grooves.

Brass

Brass is widely used in the production of various components due to its excellent machinability and attractive appearance. When grooving brass, it’s important to consider its unique characteristics. Brass typically produces small granular chips, making chip control relatively easier compared to other materials. This allows for efficient and high-quality grooving.

Selecting the right grooving tool material is another crucial aspect to consider in groove machining. Carbide inserts are often the preferred choice due to their durability and precision. These inserts ensure efficient chip evacuation and provide excellent surface finishes. Pairing the correct grooving tool material with the specific material being machined is essential for optimal results.

Effective chip control is vital in groove machining. It helps prevent chip buildup, tool breakage, and damage to the workpiece. Additionally, the use of coolant or lubricant can improve chip evacuation and reduce cutting temperature, leading to better tool life and surface finish.

Grooving Tool Selection

Choosing the right grooving tools is crucial for efficient and high-quality grooving machining. Different types of grooving tools are designed to meet specific machining needs, ensuring precise and accurate results. Here are some essential grooving tools used in the machining industry:

Grooving Inserts

Grooving inserts are key components of grooving tools. These inserts are carefully tailored to the material being machined and the desired groove geometry. Proper selection of grooving inserts significantly impacts the surface finish and accuracy of the machining process.

Grooving Turning Tools

Grooving turning tools are specifically designed to create grooves in workpieces. With their unique cutting edge geometry, these tools allow for precise and controlled grooving operations. Grooving turning tools are ideal for applications that require both turning and grooving functions.

Parting Tools

Parting tools are used to separate a workpiece into two or more parts. These tools create narrow grooves that extend through the entire depth of the workpiece. Parting tools are commonly used in manufacturing industries to produce accurate and clean parting-off operations.

Internal Grooving Tools

Internal grooving tools are designed to create grooves within hollow workpieces. These tools allow for precise machining inside the workpiece, enabling the creation of intricate internal features and improving overall part quality.

External Grooving Tools

External grooving tools are used to create grooves on the outer surface of workpieces. These tools are essential for applications that require precise external groove formation, such as creating keyways or thread reliefs.

Face Grooving Tools

Face grooving tools are specifically designed to create axially-aligned grooves on the end face of a workpiece. These tools enable the creation of accurate grooves that are perpendicular to the workpiece’s face, providing versatility and precision in machining operations.

Choosing the appropriate grooving tool for a specific machining task is essential to achieve high-quality results. Each tool serves a specific purpose, allowing machinists to optimize the machining process and produce accurate and efficient grooves.

| Grooving Tool | Application |

|---|---|

| Grooving Inserts | Tailored to the material and groove geometry |

| Grooving Turning Tools | For turning and grooving operations |

| Parting Tools | For parting-off operations |

| Internal Grooving Tools | For creating grooves within hollow workpieces |

| External Grooving Tools | For creating grooves on the outer surface of workpieces |

| Face Grooving Tools | For creating axially-aligned grooves on the end face of workpieces |

Common Challenges in Grooving Machining

Grooving machining poses various challenges that can impact the success of the operation. Addressing these challenges is necessary to ensure optimal results. Some of the common challenges in grooving machining include:

Premature tool wear

Premature tool wear is a frequent issue, especially when working with harder materials. It reduces the tool’s effectiveness and requires frequent tool changes, leading to increased downtime and costs.

Poor surface finish

Achieving a desired surface finish can be challenging if a dull tool is used or if cutting techniques are not appropriate. This can result in rough or imperfect surfaces, affecting the overall quality of the grooves.

Tool deflection

Tool deflection occurs when the tool bends or flexes under the cutting forces, leading to inaccuracies in groove dimensions and shape. It can compromise the precision and integrity of the grooving operation.

Chip control

Effective chip control is crucial in grooving machining to prevent chip buildup, which can cause chip recutting, tool damage, and poor surface finish. Proper chip management techniques are essential for a smooth and efficient machining process.

Overcoming these challenges requires careful attention to various factors. A combination of a sharp cutting edge, proper tool selection and maintenance, optimized cutting parameters, and appropriate coolant/lubricant usage can help mitigate these challenges and ensure high-quality groove machining.

Best Practices and Tips for Grooving Machining

When it comes to grooving machining, implementing the right practices and tips can significantly enhance efficiency, productivity, and cost-effectiveness. By following these recommendations, you can optimize your machining process and achieve superior results.

Utilize High-Pressure Coolant

One essential practice in grooving machining is the use of high-pressure coolant. This technique enhances tool life by effectively removing heat from the cutting zone, reducing built-up edge and tool wear. High-pressure coolant also improves chip evacuation, ensuring a cleaner cutting environment and boosting overall productivity.

Control the Toolcrib

Controlling the toolcrib is crucial for efficient grooving machining. By implementing a disciplined tool management system, you can ensure the availability of the right tools at the right time. This enables quick tool changeover, minimizes machine downtime, and optimizes the overall machining process.

Optimization Over Maximization

Instead of pushing tools to their maximum limits, focus on optimizing their lifespan. Balancing tool wear and process stability not only improves the quality of your grooving operations but also reduces tooling costs in the long run. It’s important to find the sweet spot that maximizes efficiency without compromising tool performance.

Regular Maintenance

Regular maintenance is key to achieving consistent and reliable grooving results. Keep your work area clean to prevent chips and debris from accumulating, which can lead to tool damage or even workpiece defects. Additionally, regularly inspecting tool bodies ensures their integrity and avoids potential tool failure during machining.

Documentation and Training

Proper documentation and continuous training are essential components of effective grooving machining. Documenting machining parameters, tool setups, and process improvements allows for knowledge retention and enables faster troubleshooting. Conducting regular training sessions ensures that your team is updated on the latest techniques and best practices, improving overall workflow and skillset.

Implementing these best practices and tips in your grooving machining process will not only optimize efficiency but also result in higher-quality products. By utilizing high-pressure coolant, controlling the toolcrib, prioritizing optimization, conducting regular maintenance, and emphasizing documentation and training, you can achieve superior grooving results and stay ahead in the competitive manufacturing industry.

Limitations of CNC Machining in Geometry

While CNC machining offers high precision and accuracy, it does have some limitations when it comes to creating certain geometries. These limitations can present challenges in achieving specific design features and may require alternative solutions. In this section, we will explore the geometry challenges faced in CNC machining, such as sharp internal corners and undercut features, and discuss workholding solutions to overcome these limitations.

Sharp Internal Corners

Creating sharp internal corners with round, rotating tools can be difficult in CNC machining. Due to the tool’s shape, it tends to generate rounded corners instead of sharp angles. This limitation can affect the overall design of parts that require precise internal corners.

Undercut Features

Undercut features, such as dovetails and T-slots, are also challenging to achieve in CNC machining. These features require the tool to reach and machine areas that are not easily accessible from certain angles. Consequently, machining undercut features may require specialized tooling or alternative machining techniques.

Workholding Solutions

To overcome the limitations of CNC machining in geometry, proper workholding solutions play a crucial role. Effective workholding ensures that the workpiece remains stable and secure during machining operations, reducing the risk of unwanted movement or vibrations that can affect the accuracy of the geometries being machined.

There are various workholding solutions available, including chucks, collets, vises, fixtures, and jigs. The choice of workholding device depends on factors such as the size and shape of the workpiece, the machining requirements, and the desired outcome. Customized workholding solutions may be necessary for complex geometries or unique part configurations.

Implementing the right workholding solution not only helps overcome the limitations of CNC machining but also ensures the viability and cost-effectiveness of the entire machining process.

| Workholding Solution | Features | Advantages |

|---|---|---|

| Chucks | Used for holding cylindrical or irregular-shaped workpieces | Secure and accurate gripping of the workpiece |

| Collets | Provide high concentricity and repeatability for holding cylindrical workpieces | Quick and easy setup with excellent gripping force |

| Vises | Used for securing flat or irregular-shaped workpieces | Flexible and adjustable for various part sizes and orientations |

| Fixtures | Customized workholding devices for specific part configurations | Ensures optimal support and positioning of the workpiece |

| Jigs | Used for guiding and supporting the workpiece during machining | Enhances precision and consistency in machining operations |

Importance of Workholding in CNC Machining

Workholding is an essential aspect of CNC machining as it ensures the stability and immobility of the workpiece during the machining process. By securely holding the workpiece in place, workholding devices enable precise and accurate machining operations, resulting in high-quality and consistent output. Various workholding devices are utilized in CNC machining, including chucks, collets, vises, fixtures, and jigs.

Chucks are widely used in CNC machining to hold cylindrical workpieces securely. They are available in different types, such as three-jaw chucks and four-jaw chucks, allowing for versatile workpiece holding options. Collets, on the other hand, are ideal for gripping round or hexagonal workpieces with a high level of precision.

Vises are commonly used for securing flat or irregularly shaped workpieces. They provide a stable and rigid grip, allowing for multiple face machining operations. Fixtures and jigs are specialized workholding devices that are designed for specific machining applications. Fixtures are custom-built to hold complex workpieces in position, while jigs assist in guiding the machining tool accurately.

Customized workholding solutions are sometimes necessary to accommodate unique machining requirements. These custom solutions may involve the design and fabrication of specialized fixtures or the use of dedicated workholding devices tailored to the specific dimensions and geometries of the workpiece.

Choosing the appropriate workholding devices and optimizing their setups is crucial in CNC machining. Proper workholding enhances process stability, reduces vibration, and minimizes the risk of workpiece movement, which can lead to poor surface finish and dimensional inaccuracies. Additionally, effective workholding setups maximize spindle usage time by minimizing setup and changeover times, improving overall production throughput.

Advantages of Effective Workholding in CNC Machining

Implementing proper workholding techniques and devices in CNC machining offers several advantages:

- Enhanced accuracy and precision in machining operations

- Reduced risk of workpiece movement and related errors

- Improved surface finish and dimensional accuracy

- Optimized spindle usage time and increased production throughput

| Workholding Device | Description |

|---|---|

| Chucks | Mainly used for securely holding cylindrical workpieces. |

| Collets | Ideal for gripping round or hexagonal workpieces with precision. |

| Vises | Commonly used for securing flat or irregularly shaped workpieces. |

| Fixtures | Custom-built devices for holding complex workpieces in position. |

| Jigs | Assist in guiding the machining tool accurately. |

Optimizing CNC Workholding

When it comes to CNC machining, optimizing workholding is crucial for achieving precise and efficient results. By implementing various strategies, you can minimize tool pressure, maximize surface speed, and ensure smooth tool changeover, ultimately enhancing productivity and reducing downtime.

Minimizing Tool Pressure

One key aspect of optimizing workholding is minimizing tool pressure. By using a larger cutting depth, you can reduce the stress on the tools. This not only prolongs their lifespan but also improves the overall machining process. Minimizing tool pressure allows for more consistent and reliable cutting, resulting in high-quality finished products.

Maximizing Surface Speed

To further optimize CNC workholding, it is essential to maximize surface speed. By increasing the cutting speed without compromising tool integrity, you can enhance productivity and achieve faster machining times. Maximizing surface speed helps reduce cycle times and allows for more efficient material removal.

Utilizing Wiper Inserts

Another effective strategy in workholding optimization is the use of wiper inserts. Wiper inserts are specifically designed for finishing operations, offering superior surface finishes at high feed rates. By incorporating wiper inserts into your machining process, you can achieve smoother and more precise finishes, minimizing the need for post-machining treatments.

Large Lead Angles

Large lead angles play a crucial role in workholding optimization. By utilizing tools with large lead angles, you can reduce notching and achieve higher feed rates. This results in faster material removal and improved overall machining efficiency. Large lead angles provide enhanced chip control, leading to better surface finishes and reduced tool wear.

Coordinated Tool Changeover

Efficient tool changeover is an essential aspect of optimizing workholding in CNC machining. Coordinating tool changeovers reduces machine downtime and provides predictable working intervals. By streamlining the tool changeover process, you can maximize productivity and achieve uninterrupted machining operations.

Implementing these strategies for optimizing CNC workholding can significantly improve the efficiency, precision, and overall success of your machining process. By minimizing tool pressure, maximizing surface speed, utilizing wiper inserts, incorporating large lead angles, and coordinating tool changeovers, you can achieve outstanding results and enhance your manufacturing capabilities.

| Optimization Strategy | Benefits |

|---|---|

| Minimizing Tool Pressure | – Prolongs tool lifespan – Improves machining consistency |

| Maximizing Surface Speed | – Enhances productivity – Reduces cycle times |

| Utilizing Wiper Inserts | – achieves superior surface finishes – reduces the need for post-machining treatments |

| Large Lead Angles | – Reduces notching and improves chip control – Enhances surface finishes |

| Coordinated Tool Changeover | – Reduces machine downtime – Provides predictable working intervals |

Continuous Improvement in CNC Machining

Continuous improvement is a vital aspect of CNC machining, driving enhanced efficiency, productivity, and overall success. To achieve this, implementing digital tools for documentation and workflow management is crucial. These tools streamline operations, allowing for better organization of data and preventing knowledge loss. By leveraging digital tools, such as cloud-based platforms and software solutions, CNC machining companies can effectively track and monitor their processes, identify areas for improvement, and make data-driven decisions to optimize performance.

Another essential element of continuous improvement is continuous training. Providing regular training sessions for employees ensures that they stay up-to-date with the latest industry trends, technologies, and best practices. Ongoing training allows employees to enhance their skills, adapt to new challenges, and reach their full potential. It also helps in retaining valuable talent, as employees feel valued and supported in their professional growth.

Seeking application advice from cutting and machine tool application engineers is another valuable strategy for continuous improvement in CNC machining. These experts have in-depth knowledge and experience in optimizing machining processes. By consulting with them, manufacturers can gain valuable insights, identify potential areas of improvement, and implement effective strategies to enhance efficiency, quality, and productivity. Whether it’s selecting the right tools, fine-tuning cutting parameters, or exploring new techniques, their expertise can make a significant difference in CNC machining operations.

Embracing an ongoing improvement mindset is crucial for long-term success in CNC machining. By establishing a culture of continuous improvement, companies can foster innovation, encourage collaboration, and drive positive change. Emphasizing the importance of documentation, digital tools, continuous training, and seeking application advice, manufacturers can consistently improve their processes, stay ahead of the competition, and deliver high-quality products and services to their customers.