These machines offer an array of benefits, but it’s essential to acknowledge that they also come with certain limitations. In this blog, we’ll delve into the aspects where CNC machines fall short, giving you a comprehensive understanding of their drawbacks.

- Creativity and Adaptability: While CNC machines excel at producing repetitive and precise tasks, they lack the creativity and adaptability of skilled human artisans. Artistic designs, intricate detailing, and customized craftsmanship are challenging for CNC machines to replicate. The human touch and ingenuity in artistry cannot be easily replicated by computer programs, limiting the machine’s ability to cater to highly creative and unique projects.

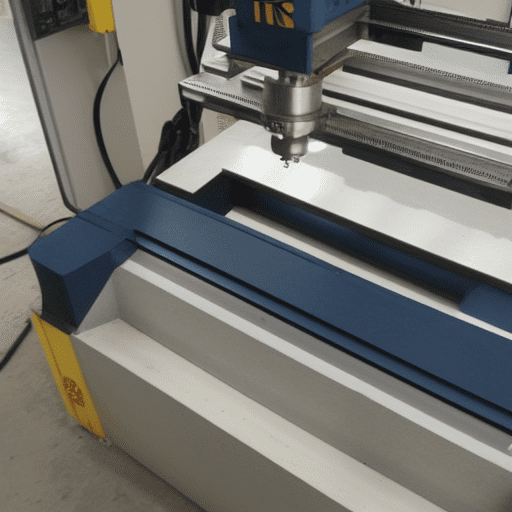

- Initial Investment and Maintenance Costs: One of the significant drawbacks of CNC machines is their initial cost. These machines are a considerable investment, and small businesses or startups may find it challenging to afford them. Additionally, ongoing maintenance and regular servicing are necessary to keep the CNC machine in optimal working condition. These maintenance costs can add up, making it financially demanding for some businesses.

- Programming Complexity: CNC machines require programming instructions to carry out specific tasks accurately. Creating the CNC program can be complex and time-consuming, especially for intricate designs or 5-axis machining. Skilled CNC programmers are essential to ensure the machine operates flawlessly, but their expertise comes at a premium, adding to the overall expenses.

- Material Constraints: While CNC machines can work with various materials, they may not be suitable for all types. For example, materials that are too soft or too brittle may be challenging to machine effectively. Additionally, some exotic materials or composites may pose difficulties due to their unique properties, limiting the choice of materials for specific applications.

- Risk of Errors: Although CNC machines are incredibly accurate, they are not immune to errors. A single mistake in the CNC program, a tooling malfunction, or an improper setup can lead to costly errors in the final product. Regular quality control checks and skilled operators are crucial to minimize the risk of such errors.

- Limited Human Intuition: CNC machines lack the ability to adapt to unforeseen circumstances during the machining process. Unlike human operators who can make real-time adjustments based on intuition and experience, CNC machines strictly follow programmed instructions. This limitation may lead to inefficiencies and potential wastage of materials if unexpected challenges arise.

CNC machines undoubtedly offer numerous advantages, revolutionizing manufacturing and increasing productivity. However, it’s essential to recognize their limitations and understand that they are not a one-size-fits-all solution for every manufacturing requirement. Balancing the strengths and weaknesses of CNC machines with traditional craftsmanship and skilled human intervention can lead to the best results in various industries. Embracing both the precision of CNC and the creativity of human craftsmanship can help businesses achieve exceptional products and sustainable growth.

Expert thought on the disadvantages of CNC Machines

- “While CNC machines offer unparalleled precision and efficiency in mass production, they may not be the best choice for small-scale or one-off projects due to the high setup and programming costs involved.” – Manufacturing Expert

- “CNC machines have limitations when it comes to handling complex artistic designs and custom craftsmanship, as they lack the creativity and intuition of skilled human artisans.” – Industrial Designer

- “The initial investment and ongoing maintenance costs of CNC machines can be significant, making it challenging for small businesses to adopt this technology without careful financial planning.” – Business Analyst

- “Programming and operating CNC machines require specialized knowledge and training, and finding and retaining skilled CNC operators can be a challenge for manufacturers.” – CNC Machining Consultant

- “CNC machines may have material constraints, as certain materials, such as soft or brittle ones, may be difficult to machine accurately using this technology.” – Materials Engineering Expert

- “Although CNC machines offer automation, they still require human supervision for setup, monitoring, and quality control, which can limit the potential for complete lights-out manufacturing.” – Automation Specialist

- “The inflexibility of CNC machines can be a drawback in dynamic production environments, where rapid design changes and quick adaptations are required.” – Manufacturing Process Engineer

- “Despite their precision, CNC machines are not exempt from errors, and a single programming mistake or mechanical issue can lead to costly scrap and rework.” – Quality Assurance Manager