The manufacturing industry has long relied on conventional machines for their various production needs, from drilling and cutting to honing and grinding. While these machines offer a considerable number of benefits, many manufacturers are now turning to Computer Numerical Control (CNC) machines for their advantages in efficiency, precision, and customization. To understand the differences between these two types of machines, let’s look at the benefits of each. Conventional machines have been around for decades, providing a reliable and cost-effective solution for many manufacturing needs. They are relatively easy to operate and maintain, making them popular with many businesses. As these machines only require manual operation, they are considered to be less expensive than CNC machines and require less extensive training. They are also very versatile, offering a range of functions for different applications. CNC machines, on the other hand, provide a more advanced solution for many manufacturers.

Rather than relying on manual operation, CNC machines are powered by computer programs that are programmed to perform specific tasks. This allows for increased automation, which can result in improved efficiency and accuracy. CNC machines are also more customizable, as they can be programmed to produce a variety of shapes and sizes. Furthermore, CNC machines are generally more reliable than conventional machines, as they can operate continuously without requiring frequent maintenance or repairs. Ultimately, the choice between conventional and CNC machines depends on the specific needs of each manufacturer. Both types of machines have their benefits, and many businesses may find that the advantages of one outweigh the disadvantages of the other. However, whichever type of machine is chosen, it is important to ensure that it is properly maintained and operated to ensure optimal performance.

How CNC Machines Have Revolutionized Manufacturing

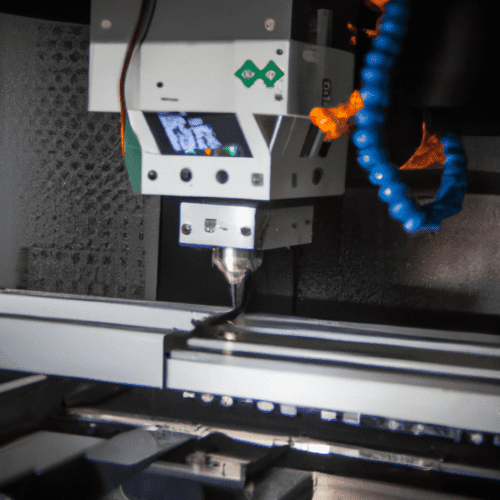

The introduction of Computer Numerical Control (CNC) machines has revolutionized manufacturing processes around the world. CNC machines are computer-controlled devices that automate the production process of a variety of materials, including metals, plastics, and composites. CNC machines are capable of performing intricate and precise operations with greater accuracy and speed than manual fabrication techniques. CNC machines are extremely versatile, with the ability to perform a wide range of operations, from simple drilling and cutting to complex milling and engraving. This versatility allows for the fabrication of complex parts that would be impossible with manual processes. Furthermore, CNC machines can process a variety of materials, including metals, plastics, and composites, allowing for the production of parts that are strong and durable.

CNC machines also offer greater precision than manual production techniques. With the ability to accurately control the speed, direction, and depth of operations, CNC machines can produce parts with greater uniformity and accuracy than manual methods. This precision allows for the production of parts with tighter tolerances, leading to an increase in product quality. CNC machines also offer greater efficiency than manual processes. By automating the manufacturing process, CNC machines can produce parts faster and more consistently than manual methods. Furthermore, CNC machines are capable of performing numerous operations in a single setup, reducing the cost of production and increasing the efficiency of the manufacturing process. The introduction of CNC machines has revolutionized the manufacturing process, providing increased precision, versatility, and efficiency. CNC machines have allowed for the fabrication of parts with greater accuracy and speed than manual processes, leading to an increase in product quality and efficiency. By automating the manufacturing process, CNC machines have enabled the production of complex parts with greater speed and accuracy than ever before.

Comparing Costs Between Conventional and CNC Machines

The cost of a CNC machine is generally more expensive than a conventional machine due to its greater complexity and precision. However, the cost difference between the two technologies can vary greatly depending on the type of machine and the specific application for which it is being used. Conventional machines are typically less expensive upfront, however they require more time and labor for set-up and operation. This can lead to increased labor costs and slower production times. CNC machines, on the other hand, require a greater initial investment but are more efficient in terms of time and labor. This can result in a lower overall cost in the long-run due to reduced labor and production costs.

The cost of a CNC machine also depends on its capabilities, accuracy and the range of materials that it can process. Generally, machines with greater capabilities and accuracy will be more expensive. Additionally, CNC machines that are able to process a greater range of materials may also cost more. Overall, the cost of a CNC machine is typically higher than a conventional machine. However, the cost difference between the two technologies can vary greatly depending on the application and the specific requirements. CNC machines may be more expensive upfront, but they often offer greater efficiency and cost savings in the long-run.

Understanding the Complexities of CNC Programming

CNC programming is an essential element in modern manufacturing. It is used to create complex parts and components for a wide range of industries, from automotive and aerospace to medical and consumer products. Understanding the complexities of CNC programming is essential for anyone involved in the manufacturing process. CNC programming consists of writing code that is used to control the actions of a CNC machine. This code must be written with precision and accuracy to ensure the desired results. It is important to understand the fundamental principles of programming, including the components of the machine and how they work together, the various commands and functions used in the code, and the various programming languages available. When writing CNC code, it is important to understand the syntax and structure of the language being used. This includes the format of the commands, the data types, and the order of operations.

Additionally, it is important to understand the data requirements for each command, as well as the safety protocols that must be followed. In addition to the code, CNC programming also requires an understanding of the machine itself. This includes understanding the basic parts of the machine, the available accessories, and the process for setting up the machine for a specific task. Additionally, it is important to understand the principles of tooling and cutting, including the various types of tools, the cutting speeds, and the cooling methods. Finally, it is important to understand the principles of machining, including the various types of materials used in the process. Understanding the different types of materials and their properties is essential for producing quality parts. Additionally, it is important to understand the principles of metrology, including how to measure and inspect parts for accuracy and precision. CNC programming is a complex process, requiring an understanding of both the code and the machine. However, with a clear understanding of the fundamentals, anyone involved in the manufacturing process can create parts with precision and accuracy.

Examining the Safety Implications of Conventional vs CNC Machines

In the manufacturing industry, the use of conventional and computer numerically controlled (CNC) machines is commonplace. While both machines have their advantages, it is important to understand the safety implications of each technology. Conventional machines, such as drill presses and lathes, are manually operated and require manual adjustments. These machines are often used for production jobs that require a high degree of precision. Despite their utility, they can pose a safety risk if not operated properly. The manual adjustment of the equipment can lead to operator error, which can cause a machine to malfunction or cause injury to the operator. Additionally, their manual operation can also lead to long periods of repetitive motions, which can cause fatigue and increase the risk of injury. In contrast, CNC machines are operated by a computer program and require minimal manual adjustment. They are often used for more complex production jobs that require intricate patterns and shapes.

While these machines are more efficient and require less manual input, they can also present safety risks. For instance, if the computer program is not properly programmed, the machine may malfunction and cause injury. Additionally, these machines can operate at a high speed and require specialized safety protocols to ensure that the operator is not harmed. In conclusion, both conventional and CNC machines can pose safety risks. It is important for manufacturers to understand the safety implications of each technology and to implement the necessary protocols to ensure that their operators are not put at risk. Furthermore, operators should be properly trained on the safe operation of the machines and be provided with the necessary protective equipment.