When considering used CNC machine parts, there are a few aspects to consider. First, you should consider the exact part that you need and consider its compatibility with your system. Make sure that the part will fit properly and function properly in your system.

You should also determine the condition of the part before purchasing. Inspect the part for any signs of wear and tear, as well as any potential defects. Check for loose components, rust, corrosion, and any signs of damage that could potentially compromise the part’s performance.

Check that the part is original and not a counterfeit or replacement part. Look for the manufacturer’s information on the part, such as a manufacturer’s name or serial number. Counterfeit parts will not have the same quality and durability, so it is best to avoid them.

When buying used CNC machine parts, it is best to buy from a reputable source. Look for a trusted source who can provide information about the part, such as where it was purchased and how it was used. Check the company’s warranties and return policies to ensure that you are covered in case of any dissatisfaction with the part.

Finally, be sure to think of the cost of the part before buying. Buying used parts can be more cost-effective than purchasing new parts, but do research online to compare prices and determine if the part is worth the price. Consider all of these factors when shopping for used CNC machine parts.

What are CNC parts used for?

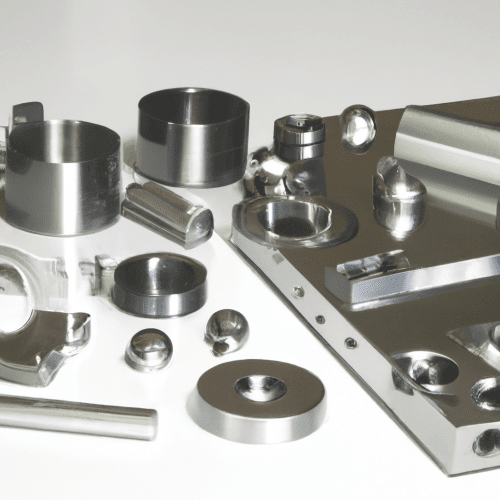

CNC parts are used in a variety of industries to manufacture a wide range of components and products. CNC parts are created using computer-controlled tools such as lathes, milling machines, and 3D printers. CNC machines are capable of producing precision parts with high accuracy, complexity, and repeatability. Examples of components manufactured with CNC parts include aircraft parts, medical implants, automotive components, and plastic components.

CNC parts have a variety of uses in a variety of industries. CNC machines are used in manufacturing to create components from raw materials with an exact and repeatable design. These parts can be used for a variety of purposes depending on the industry. In the aerospace industry, for example, CNC parts are used for creating aircraft components such as landing gear, interior panels, and engine parts. In the automotive industry, CNC parts are used for creating components for transmissions, engines, and brakes. In the medical industry, CNC parts are used for creating components for implants and prosthetics.

CNC parts provide a range of benefits to manufacturers. Using a CNC machine, parts can be quickly and precisely machined to tolerances as low as one thousandth of an inch. This allows a higher level of accuracy and detail than would be possible with manual manufacturing. CNC machines are also extremely efficient, providing a faster production cycle than traditional methods. CNC machines also provide cost savings by eliminating the need for hard tooling such as molds and dies. Finally, CNC parts are durable and can withstand the wear and tear of industrial usage.

Which machine is used in CNC machine?

CNC machines are automated machines that are used for precision machining tasks such as milling, drilling, turning, and grinding. CNC machines are typically used for high volume production and precise cutting of materials such as steel, aluminum, and other metals. Depending on the application, different types of machines are used, including lathes, mills, routers, grinders, and drill presses.

The main components of a CNC machine are a computer control system, an interface, the working tool, and the actual mechanical machining hardware. The computer control system runs the machine’s logic and commands, while the interface is the user’s medium to operate the CNC machine. The working tool is the part that physically interacts with the material to be machined, and it can be a cutting tool such as a drill, grinder, or milling tool. Lastly, the actual machining hardware consists of the motors, sliding supports, ball screws, and other components that move the cutting tool in order to create the desired shape or holes in the material.

CNC machines are also known for their ability to produce repeatable and precise parts quickly and cost effectively, as well as for their ability to perform complex operations such as turning, drilling, and milling. Additionally, CNC machines are capable of manufacturing parts with a high degree of accuracy and repeatability, making them important for precision works that involve complex geometry.

Why are CNC parts so expensive?

CNC parts are expensive for a variety of reasons, including the cost of the materials used, the cost of the machinery involved in the process, the complexity of the machining required, and the precision required for the finished product.

First, CNC parts are often made of expensive materials. Depending on the application and industry, a wide variety of materials may used, including aluminum, steel, plastic, titanium, and exotic metals. All of these materials are typically more expensive than traditional manufacturing materials like wood or cloth. This can drive up the cost of CNC parts made with these materials.

Second, CNC parts often require machinery to be machined with precision. This machinery can be expensive, and only experienced technicians can operate it. Specialized machines such as those used to cut metal, plastic, and titanium are particularly expensive, and the cost of acquiring and maintaining these machines contributes to the cost of CNC parts.

Third, the machining process to create CNC parts can be complex and require experienced machinists. This can add additional costs to the process and lead to higher prices. Furthermore, the process often requires close monitoring and tight tolerances, which requires highly skilled and experienced technicians.

Finally, a high degree of precision is often required for CNC parts, which can increase costs. Precision parts require careful attention to detail, tight tolerances, and skilled machinists. The need for precision can result in additional labor costs and a longer turnaround time for production, which can add to the cost of CNC parts.

Overall, CNC parts are expensive for a variety of reasons, including the cost of materials, the cost and complexity of the machinery, and the level of precision required. These factors combine to make CNC parts a costly endeavor, but the quality and accuracy of the finished product often justify the expense.

Is CNC machining wasteful?

The answer is that CNC machining is not necessarily wasteful. In fact, CNC machining can actually help save on material waste. By applying the exact amount of material necessary to achieve the desired outcome, CNC machining can significantly reduce the amount of waste that’s generated when producing a part or component. Additionally, CNC machining requires less human labor, which in turn can save on time, resources and energy.

CNC machining does have some drawbacks, however. Sometimes, material, tooling and energy costs can be higher than manual manufacturing processes. Thus, it is important to conduct a cost-benefit analysis and ensure that CNC machining is the best option for ground-specific needs. Ultimately, the decision is dependent on the specific application and desired outcome.

In summary, CNC machining is not necessarily wasteful. With careful planning and proper management, CNC machining can produce high-quality parts with minimal waste and cost efficiency.