Most CNC machines are manufactured in countries such as China, Japan, Germany, and the United States. These countries have the technology and resources to produce high-quality CNC machines. Additionally, these countries have extensive research and development capabilities, allowing them to continually innovate and improve CNC machines.

Exploring the CNC Machining Industry in China: How the Country is Leading the Way in CNC Manufacturing

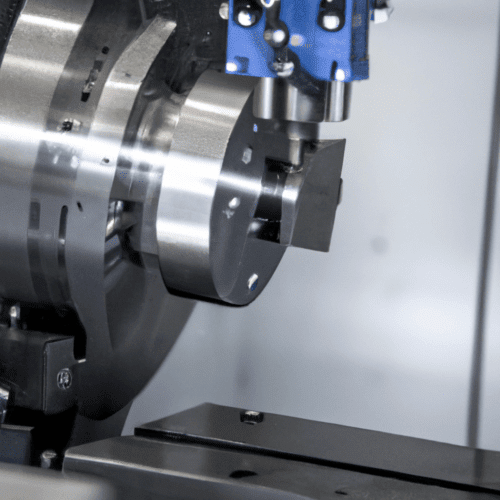

China is leading the way in CNC (Computer Numerical Control) machining, a process of using a computer to control machine tools such as lathes, mills, and grinders. This technology, which allows for the precise, repeatable production of components, has become increasingly important in a wide variety of industries. In recent years, the Chinese CNC machining industry has seen rapid growth thanks to the availability of the latest technology and the emergence of a skilled workforce. Many of the world’s leading CNC machining companies have factories in China, taking advantage of the low costs and high quality of the local manufacturing sector. The Chinese government has also taken steps to boost the CNC machining industry by investing in research and development and offering incentives to manufacturers. This has resulted in a number of new technologies, such as 5-axis machining, that have increased the precision and speed of production. In addition, the government has established quality standards for CNC machining, ensuring that Chinese products meet international standards.

The Chinese CNC machining industry has also seen the emergence of a number of new materials that can be used in the production of components. This has made it easier for companies to create custom parts that are more durable and precise. The Chinese CNC machining industry has also seen a shift towards automation, allowing for faster, more efficient production. Automated CNC machines can now be programmed to produce complex components with minimal human input. This has allowed Chinese manufacturers to stay competitive in a global market. The Chinese CNC machining industry is continuing to grow at a rapid pace, and it is clear that the country is leading the way in this field. With the latest technology, skilled workforce, and supportive government policies, China is well on its way to becoming a major force in the global CNC machining industry.

Analyzing the Benefits of Investing in a CNC Machine Made in China

Investing in a CNC machine made in China can provide numerous benefits to businesses. CNC machines are highly efficient and accurate, allowing for a greater level of precision when producing parts and components. The machines are easy to use and require minimal maintenance, making them ideal for businesses with limited resources. Additionally, the cost of purchasing a CNC machine made in China is significantly lower than that of a similar machine made in the United States, providing businesses with a great cost savings. The accuracy of CNC machines is unmatched when compared to traditional manufacturing methods. The machines are capable of producing parts with a high degree of precision, which can result in greater efficiency in production. Additionally, the use of CNC machines can reduce the amount of time needed to produce parts, as well as the amount of materials needed, resulting in a lower cost of production. The maintenance requirements for CNC machines are minimal. The machines are designed to be as user-friendly as possible, with intuitive controls and easy-to-follow instructions.

This makes them ideal for businesses with limited resources, as they require minimal technical know-how and don’t require a dedicated maintenance staff. Finally, CNC machines made in China are significantly cheaper than those made in the United States. This cost savings can be a major benefit, particularly for businesses with limited resources. By investing in a CNC machine made in China, businesses can significantly reduce their production costs without compromising on quality or precision. Overall, investing in a CNC machine made in China can provide numerous benefits to businesses, including greater accuracy and precision, reduced maintenance requirements, and cost savings. By taking advantage of these benefits, businesses can improve their efficiency and lower their production costs.

Understanding the Regulations Behind CNC Machinery Production in China

The People’s Republic of China has implemented a number of regulations governing the production of CNC machinery. These regulations are intended to ensure the safety and quality of the products produced, while also protecting the environment. The regulations are based on a number of standards, including the National Standard for Technical Requirements of CNC Machine Tools, which is based on the ISO 230-2:2006 standard. This standard covers topics such as the design, manufacture, test, and use of these machines. The regulations also include the National Quality Supervision and Inspection Regulations for CNC Machine Tools, which covers topics such as the acceptance of the machines and the inspection of them before they are put into use. The regulations also cover the safety requirements for the machines, such as ensuring that the machines are designed and manufactured in accordance with the relevant safety regulations.

The regulations also cover the requirements for the maintenance and repair of CNC machines, including the requirements for the personnel who will be performing these tasks. The regulations also cover the requirements for the disposal of CNC machines, such as the proper disposal of hazardous materials and the disposal of the machines in accordance with the relevant environmental regulations. Finally, the regulations also cover the requirements for the use of CNC machines in production. This includes topics such as the proper use of the machines, the training of personnel in their use, and the safety measures that must be taken while working with the machines. Overall, these regulations are designed to ensure that CNC machines are produced in a safe and high-quality manner, while also protecting the environment.

Investigating the Role of Quality Control in the CNC Machining Process in China

The quality control process in the CNC machining process is of paramount importance in China. CNC machining is an advanced manufacturing process that is used to create parts and components with a high level of accuracy and precision. Quality control is necessary to ensure that the finished parts and components meet all the necessary standards and specifications. Quality control in CNC machining involves the use of quality assurance tools and techniques such as visual inspection, dimensional measurements, and non-destructive testing. Quality control also involves the use of statistical process control (SPC) to monitor the process and ensure that it is operating within the specified parameters. In China, quality control is an integral part of the CNC machining process.

The Chinese government requires manufacturers to adhere to strict quality control standards. Quality control is also used to ensure that all parts and components manufactured meet the customer’s requirements. Quality control in CNC machining in China is carried out at the design stage, production stage, and post-production stage. At the design stage, the manufacturer designs the part or component according to the customer’s requirements and specifications. The manufacturer then carries out quality control checks to ensure that the part or component meets the customer’s requirements. At the production stage, quality control is carried out to ensure that the machining process is being carried out correctly. This involves checks on the machine settings, the production process, and the materials used. Quality control is also carried out on the finished parts and components to ensure that they meet the customer’s specifications.

At the post-production stage, quality control is carried out to ensure that the parts and components are in working order and can be used safely and effectively. This involves the use of testing and inspection methods to check for any defects or errors. In conclusion, quality control plays an important role in the CNC machining process in China. Quality control is used to ensure that the parts and components meet all the necessary standards and specifications and can be used safely and effectively. Quality control is also used to monitor the production process and ensure that it is operating within the specified parameters.

Exploring How the US Could Learn from Chinese CNC Manufacturing Practices

The United States has long been a leader in manufacturing and technology, yet the rise of China in the global market has led to a dramatic shift in CNC (Computer Numerical Control) manufacturing. The US has much to learn from Chinese CNC manufacturing practices, which could help to improve efficiency and reduce costs for US manufacturers. One of the key advantages that Chinese CNC manufacturers have is their ability to produce high-quality parts at a much lower cost than US manufacturers. This cost advantage is due to a combination of factors, including lower labor costs, access to cheaper materials, and a greater use of automation. Chinese CNC manufacturers have also invested heavily in research and development, which has enabled them to produce more efficient and reliable parts.

Another area in which US manufacturers can learn from Chinese CNC practices is in the use of software and automation. Chinese manufacturers have been able to reduce their reliance on manual labor by integrating software into their CNC process, which has helped to improve efficiency and reduce costs. Chinese CNC manufacturers also make use of automated production lines, which can streamline the manufacturing process and reduce the need for manual labor. Finally, US manufacturers can learn from Chinese CNC practices in terms of the use of quality control systems. Chinese manufacturers have been able to reduce waste and improve the quality of their products by investing in quality control systems that monitor and adjust the CNC process in order to ensure the production of high-quality parts. By adopting the practices outlined above, US manufacturers can reduce costs, improve efficiency, and produce higher-quality parts. As the US seeks to remain competitive in the global market, learning from Chinese CNC practices is essential.