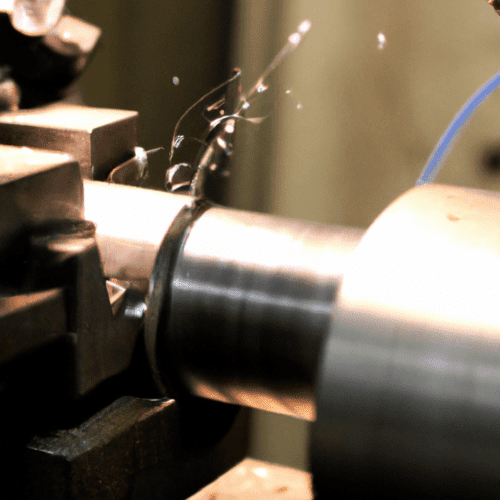

Metal can be milled using a variety of machining processes. Milling involves using a cutting tool to remove material from a workpiece in order to shape or refine it into a desired shape or form. This is done by moving the cutting tool along the surface of the workpiece in a linear direction, removing material in the form of chips. The cutting tool is typically held in a rotating spindle that is driven by a motor. Milling is commonly used to create flat surfaces, complex shapes, and features such as slots, grooves, and pockets. It can also be used to create curved and contoured surfaces. Metal can be milled with a variety of tools, such as end mills, drill bits, and reamers.

The Different Types of Metal Milling Processes

Metal milling processes are a form of machining, a process that removes metal from a workpiece to create a specific shape or size. There are several types of metal milling processes, each designed to cut and shape metal in different ways. The most common types of metal milling processes are manual milling and CNC (computer numerical control) milling. Manual milling is the traditional method of metal milling, and involves the use of manual tools to cut metal. Manual milling is usually done by a skilled machinist in a metalworking shop, and is used to create simple shapes and parts. CNC milling is a more advanced type of metal milling, and involves the use of computer-controlled machines to cut metal. CNC machines are programmed to move specific tools, such as end mills, drills, and routers, in a precise pattern to create the desired shape or size. CNC milling is often used for more complex parts, such as those with intricate shapes or tight tolerances.

Other types of metal milling processes include electrochemical milling, electrical discharge machining, and laser cutting. Electrochemical milling is a process that uses electrolysis to cut metal. Electrical discharge machining uses electrical sparks to remove metal from the workpiece, while laser cutting uses a laser to cut and shape metal. Both of these processes are often used for producing small and complex parts. Metal milling processes are used in many different industries, from automotive manufacturing to aerospace engineering. The type of metal milling process used depends on the desired shape or size and the complexity of the workpiece. All metal milling processes have their advantages and disadvantages, and selecting the right type of process can be critical to the success of a project.

Tips for Milling Metal Safely and Efficiently

Metal milling can be a dangerous and time-consuming process. Here are some tips to help you mill metal safely and efficiently.

1. Wear the right protective gear. It’s important to wear protective gear, such as safety glasses, gloves, and a respirator when working with metal.

2. Select the right tool for the job. Different metals require different types of tools. Be sure to use the correct type of milling tool for the metal you’re working with.

3. Secure the workpiece. Use a vice or other secure device to firmly hold the workpiece in place. This will help ensure that the milling process is both safe and accurate.

4. Use the correct speed. The speed of the milling tool should be adjusted according to the type of metal being milled. Adjust the speed to prevent the tool from overheating or breaking due to excessive force.

5. Take your time. Rushing through the milling process can lead to mistakes and injuries. Before starting, make sure to have a plan and take your time to ensure accuracy and safety. By following these tips, you can mill metal safely and efficiently. Be sure to take the necessary precautions and plan ahead to ensure that the process is both safe and successful.

How to Choose the Right Tool for Milling Metal

Milling metal is a highly technical process that requires the right tool to produce the desired end product. It is important to consider several factors when selecting the correct tool for milling metal, including the material of the workpiece, the size of the job, the type of milling, and the desired finish. The material of the workpiece is an important factor when selecting the right tool for milling metal. Different metals have different properties, which require different types of tools for milling. For instance, softer metals may require sharper, more abrasive tools to achieve the desired finish, while harder metals may require tools with a more durable cutting edge. The size of the job should also be taken into consideration when choosing the right tool for milling metal. Smaller jobs can typically be completed with hand-held milling tools, while larger jobs may require more powerful machines, such as a CNC milling machine.

The type of milling being performed should also be considered when selecting the right tool for milling metal. Different milling processes require different tools. For instance, circular milling requires a round cutting tool, while slot milling requires an end mill. The desired finish is another factor to consider when selecting the right tool for milling metal. Different tools will produce different finishes. For instance, a ball end mill will produce a rounded edge, while a square end mill will produce a sharp corner. By taking into consideration the material of the workpiece, the size of the job, the type of milling, and the desired finish, it is possible to select the right tool for milling metal. The right tool will ensure a successful result and will make the milling process much smoother.

The Benefits of CNC Milling for Metal Manufacturing

CNC milling is a type of metal manufacturing process that uses computerized numerical control (CNC) machines to shape and cut metal with precision and accuracy. CNC milling services offer a wide range of benefits to businesses that need custom metal parts and components. Here are some of the most important benefits of CNC milling for metal manufacturing. First, CNC milling is highly accurate and precise. The machines are programmed to cut with extreme accuracy and precision, meaning that CNC milling can produce complex parts with complex shapes. This makes it ideal for producing intricate parts such as gears and sprockets, as well as components with multiple holes or cutouts. Second, CNC milling is a cost-effective method of manufacturing. CNC milling machines are computer-controlled, meaning that the same machine can be used to produce multiple parts with minimal setup time. This reduces labor costs, as well as the cost of materials. Third, CNC milling is fast and efficient. Because the machines are programmed and controlled by computers, the entire process is automated and can be completed quickly and accurately.

This makes CNC milling an ideal choice for businesses that need to produce large numbers of parts in a short amount of time. Finally, CNC milling is a safe and reliable method of metal manufacturing. The machines are equipped with safety features such as emergency stops and sensors to prevent accidents and malfunctions. This ensures that CNC milling is always a safe and reliable process. Overall, CNC milling offers many advantages to businesses that need custom metal parts and components. This cost-effective, accurate, fast, and reliable method of metal manufacturing is ideal for businesses that need to produce complex parts in short amounts of time.

Understanding the Challenges of Machining Hard Metals

Machining hard metals presents a unique set of challenges to those involved in the metalworking industry. Hard metals such as stainless steel, titanium, and hardened tool steel require more powerful cutting tools and higher cutting speeds than softer metals, which can quickly wear out a tool. Additionally, hard metals generate more heat when being machined, making them more difficult to work with and requiring a higher level of skill and experience to achieve the desired results. Machining hard metals also requires specialised cutting fluids to reduce friction and heat, as well as to improve the cutting process. These fluids must be able to withstand the higher temperatures generated by the hard metals and must be able to cool the tools and workpiece, as well as lubricate the cutting edges. Due to the higher cutting speeds and temperatures generated by machining hard metals, the cutting tools must be made of high quality materials that can withstand the stresses of machining.

Special tool coatings can also be used to provide additional protection against wear and heat. Finally, the machining process must be carefully monitored to ensure that the tool is not pushed too hard or allowed to get too hot. This requires a skilled operator who can pay attention to the cutting process and adjust the cutting parameters as necessary. In short, machining hard metals is a challenging task that requires a combination of skill, experience, and specialised tools and cutting fluids. With these elements in place, however, it is possible to achieve the desired results when machining hard metals.