A CNC (Computer Numerical Control) system is a computer-controlled system used to automate the production of parts and components. It is used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC systems are typically composed of three main components: the controller, the machine, and the software.

The controller is the “brain” of the CNC system. It is responsible for interpreting the instructions from the software and sending the appropriate signals to the machine. The controller can be either a dedicated computer or a programmable logic controller (PLC).

The machine is the physical device that performs the actual machining operations. It is typically composed of a spindle, a table, and a cutting tool. The spindle is the rotating part of the machine that holds the cutting tool. The table is the platform on which the workpiece is placed. The cutting tool is the device that actually performs the machining operations.

The software is the program that tells the controller what to do. It is typically written in a language such as G-code or CNC-specific languages such as Fanuc or Haas. The software is responsible for generating the instructions that the controller will send to the machine.

There are several different types of CNC systems, each designed for a specific purpose. The most common types of CNC systems are milling machines, lathes, routers, and plasma cutters. Milling machines are used to cut metal and other materials into shapes and components. Lathes are used to shape metal and other materials into cylindrical shapes. Routers are used to cut and shape wood and other materials. Plasma cutters are used to cut metal and other materials into shapes and components.

In addition to these types of CNC systems, there are also specialty CNC systems such as 3D printers, laser cutters, and waterjet cutters. 3D printers are used to create three-dimensional objects from a digital file. Laser cutters are used to cut and engrave materials such as wood, metal, and plastic.

What is VMC machine?

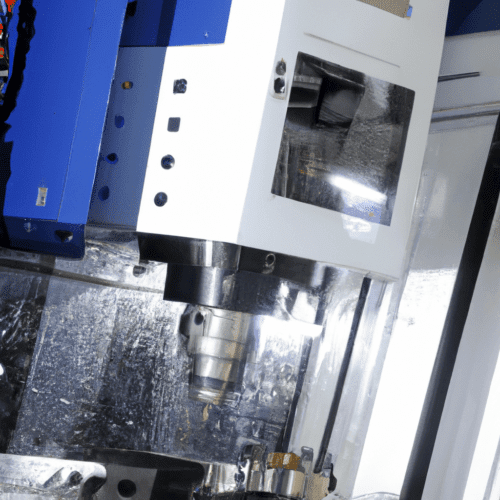

A VMC machine, or Vertical Machining Center, is a type of computer numerical control (CNC) machine tool that uses computer-controlled cutting tools to shape and form metal and other materials. It is typically used for machining operations such as drilling, milling, and tapping. VMC machines are typically used in the manufacturing industry for producing parts and components for a variety of products.

VMC machines are typically composed of a spindle, a table, and a column. The spindle is the rotating cutting tool that is used to shape and form the material. The table is the platform that the material is placed on and the column is the vertical support structure that holds the spindle and table in place. The spindle is driven by a motor and is connected to a computer that controls the speed and direction of the spindle.

The computer is programmed with a set of instructions that tell the machine how to move the spindle and table in order to shape and form the material. The instructions are typically written in a computer language such as G-code or M-code.

How many axis are there in VMC machine?

A VMC (vertical machining center) is a type of CNC (computer numerical control) machine tool that uses computerized controls to operate machine tools such as lathes, mills, and grinders. VMCs are typically used to produce precision parts and components with tight tolerances. VMCs are typically used in the manufacturing of complex parts and components, such as those used in the aerospace, automotive, and medical industries.

VMCs typically have three axes of motion: the X-axis, Y-axis, and Z-axis. The X-axis is the horizontal axis, the Y-axis is the vertical axis, and the Z-axis is the depth axis. The X-axis and Y-axis are used to move the cutting tool across the surface of the workpiece, while the Z-axis is used to move the cutting tool up and down. Some VMCs may also have additional axes of motion, such as a fourth axis (A-axis) or a fifth axis (B-axis).

What are two types of CNC machines?

CNC (Computer Numerical Control) machines are automated machines that are used to perform a variety of tasks in manufacturing and other industries. They are programmed to perform specific tasks with precision and accuracy, and can be used to produce a wide range of products. There are two main types of CNC machines: milling machines and lathes.

Milling machines are used to cut and shape materials such as metal, wood, and plastic. They use a rotating cutting tool to remove material from the workpiece. The cutting tool is moved in three directions (X, Y, and Z) to create the desired shape. Milling machines can be used to create complex shapes and can be used for a variety of applications, such as creating molds, dies, and other components.

Lathes are used to shape materials such as metal, wood, and plastic. They use a rotating cutting tool to remove material from the workpiece. The cutting tool is moved in two directions (X and Z) to create the desired shape.

Why is CNC important?

Computer Numerical Control (CNC) is an important technology in modern manufacturing. It is a process in which a computer is used to control the movement of tools and machinery in order to create parts and products with a high degree of accuracy and repeatability. CNC is used in a wide variety of industries, from aerospace and automotive to medical and consumer products.

CNC is important because it allows for the automation of complex manufacturing processes. By using a computer to control the movement of tools and machinery, CNC can produce parts and products with a high degree of accuracy and repeatability. This eliminates the need for manual labor and reduces the amount of time and money required to produce a product. Additionally, CNC can be used to produce parts and products with complex shapes and features that would be difficult or impossible to produce with traditional manufacturing methods.

What are 3 types of CNC machines?

CNC machines are computer-controlled machines used for cutting, drilling, grinding, and other manufacturing processes. There are three main types of CNC machines: milling machines, lathes, and routers.

Milling machines are used to cut and shape metal and other materials. They use a rotating cutting tool to remove material from the workpiece. The cutting tool is usually a drill bit, end mill, or face mill. Milling machines can be used to create complex shapes and contours, as well as to drill holes and create slots.

Lathes are used to shape metal and other materials by rotating them against a cutting tool. The cutting tool is usually a single-point cutting tool, such as a drill bit, chisel, or reamer. Lathes can be used to create complex shapes and contours, as well as to drill holes and create slots.

What is the difference between CNC turning and CNC milling?

CNC (Computer Numerical Control) turning and CNC milling are both forms of subtractive manufacturing, meaning that material is removed from a workpiece to create a desired shape. The primary difference between CNC turning and CNC milling is the way in which the workpiece is held and rotated. In CNC turning, the workpiece is held in a chuck and rotated while a cutting tool is fed into the rotating workpiece. This process is used to create cylindrical parts with smooth finishes. In CNC milling, the workpiece is held stationary while the cutting tool is moved in multiple axes to create the desired shape. This process is used to create complex shapes with precise dimensions.

CNC turning is generally used for parts that require a high degree of accuracy and surface finish, such as shafts, pins, and bushings. CNC milling is used for parts that require complex shapes and precise dimensions, such as engine blocks and molds.

How are CNC machines classified?

CNC machines are classified according to the type of control system they use. The most common types of CNC machines are classified as either open-loop or closed-loop systems. Open-loop systems are those that do not use feedback from the machine to adjust the cutting parameters. These machines are typically used for simple operations such as drilling and milling. Closed-loop systems, on the other hand, use feedback from the machine to adjust the cutting parameters. This type of system is used for more complex operations such as contouring and 3D machining.

In addition to the type of control system, CNC machines are also classified according to the type of motion they are capable of. The most common types of motion are linear, circular, and helical. Linear motion is used for operations such as drilling and milling, while circular motion is used for operations such as contouring and 3D machining. Helical motion is used for operations such as threading and reaming.

What are the 7 basic types of machine tools?

The 7 basic types of machine tools are lathes, milling machines, drilling machines, grinding machines, power saws, presses, and EDM (electrical discharge machining) machines.

Lathes are used to shape metal, wood, or other materials by rotating the material while a cutting tool is applied to it. Lathes can be used to create a variety of shapes, including cylinders, cones, and irregular shapes.

Milling machines are used to shape metal, wood, or other materials by cutting away material with a rotating cutting tool. Milling machines can be used to create a variety of shapes, including flat surfaces, curved surfaces, and irregular shapes.

Drilling machines are used to create holes in metal, wood, or other materials. Drilling machines can be used to create a variety of hole sizes and shapes, including round, square, and irregular holes.

Grinding machines are used to shape metal, wood, or other materials by grinding away material with a rotating grinding wheel.

How many types of machining are there?

Machining is a manufacturing process in which parts are cut from a raw material using a variety of tools and techniques. It is a subtractive process, meaning that material is removed from the workpiece to create the desired shape. There are many different types of machining, each with its own advantages and disadvantages.

The most common types of machining are turning, milling, drilling, grinding, and sawing. Turning is the process of cutting a cylindrical shape from a workpiece, usually using a lathe. Milling is the process of cutting a flat surface on a workpiece, usually using a milling machine. Drilling is the process of creating a hole in a workpiece, usually using a drill press. Grinding is the process of removing material from a workpiece using an abrasive wheel. Sawing is the process of cutting a workpiece into two or more pieces, usually using a saw.

What are examples of CNC machines?

CNC (Computer Numerical Control) machines are automated machines that are programmed to perform specific tasks with precision and accuracy. They are used in a variety of industries, including manufacturing, automotive, aerospace, and medical. Examples of CNC machines include milling machines, lathes, routers, plasma cutters, and laser cutters.

Milling machines are used to cut and shape metal and other materials. They use a rotating cutting tool to remove material from the workpiece. Lathes are used to shape cylindrical parts by rotating the workpiece while a cutting tool is held against it. Routers are used to cut and shape wood and other materials. They use a rotating cutting tool to remove material from the workpiece. Plasma cutters are used to cut metal and other materials with a high-temperature plasma arc. Laser cutters are used to cut and shape metal and other materials with a high-powered laser beam.

What is a 2 axis CNC machine?

A 2 axis CNC machine is a computer numerically controlled (CNC) machine that is capable of moving in two directions. It is a type of machine tool that uses computer-controlled motors to move a cutting tool along two axes of motion. This type of machine is used to create parts with complex shapes and features, such as those found in the aerospace, automotive, and medical industries.

The two axes of motion are typically referred to as the X and Y axes. The X axis is the horizontal axis, and the Y axis is the vertical axis. The cutting tool is moved along these axes to create the desired shape. The cutting tool is typically a drill bit, router bit, or end mill.

The CNC machine is programmed using a computer-aided design (CAD) program. The CAD program is used to create a 3D model of the part that is to be created. The 3D model is then converted into a set of instructions that the CNC machine can understand.

What is CNC machine full form?

The full form of CNC is Computer Numerical Control. CNC machines are automated machines that are used to perform a variety of tasks in manufacturing and other industries. They are programmed to perform specific tasks, such as cutting, drilling, grinding, and milling, with a high degree of accuracy and precision. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and electronics. CNC machines are typically controlled by a computer program, which is written in a language such as G-code or CNC programming language. The program is then loaded into the CNC machine, which then follows the instructions given by the program. CNC machines are used to produce a variety of products, including parts for cars, aircraft, medical devices, and consumer electronics. CNC machines are also used in the production of furniture, musical instruments, and other items.

What is G code in CNC?

G code is a programming language used to control automated machine tools such as CNC (Computer Numerical Control) machines. It is a language that is used to tell the machine what to do and how to do it. G code is used to control the motion of the machine, as well as the speed and feed rate of the cutting tool. It is also used to control the spindle speed, coolant, and other machine functions. G code is a very versatile language and can be used to control a variety of machines, from simple lathes to complex multi-axis CNC machines. G code is also used to control the operation of robots and other automated systems. G code is a very powerful language and is used in many industries, from aerospace to automotive. G code is also used in 3D printing and additive manufacturing. G code is a very important part of CNC programming and is used to create the instructions that the machine will follow. G code is a very precise language and is used to ensure that the machine is able to accurately and consistently produce the desired results.