The exact cost of a CNC machine depends on a range of factors, including the type of machine, its size and capabilities, and the manufacturer. CNC machines can cost anywhere from a few thousand dollars for a basic, entry-level model to hundreds of thousands of dollars for a highly advanced, industrial-grade machine. Other factors that can affect the cost of a CNC machine include the cost of any additional features or accessories, as well as any applicable taxes or shipping fees.

The Different Price Points of CNC Machines: Understanding the Costs of Investing in Automated Machinery

Investing in a CNC machine has become increasingly popular for businesses and individuals alike. CNC machines are automated machines that can be used to manufacture products, parts, and components with a higher level of precision than manual processes. The cost of CNC machines can vary greatly depending on the type, size, and speed of the machine. This article will provide an overview of the different price points associated with CNC machines to help potential buyers understand the costs of investing in automated machinery. For small-scale projects, the most affordable CNC machines are desktop models. These machines are designed to fit on a desktop or workbench and are typically used for smaller parts and components. Most desktop CNC machines cost between $500 and $2,500 and are capable of performing simple cutting, drilling, and engraving operations. For larger projects, a more powerful machine is needed. Medium-sized CNC machines are designed for industrial use and are capable of cutting, drilling, and engraving larger parts and components. These machines can cost anywhere from $5,000 to $50,000 and are typically used for more complex manufacturing tasks.

For the largest projects, heavy-duty CNC machines are needed. These machines are typically used for industrial manufacturing and can cost anywhere from $50,000 to over $100,

1. Heavy-duty CNC machines are capable of performing complex operations and can handle large parts and components with ease. When investing in a CNC machine, it is important to understand the different price points associated with the different types of machines. Although desktop models are the most affordable option, they are not suitable for industrial or large-scale projects. Medium-sized and heavy-duty CNC machines are more expensive but are necessary for larger projects. Understanding the costs associated with CNC machines can help potential buyers make an informed decision about the type of machine they need.

Exploring the Pros and Cons of CNC Machines and Their Costs

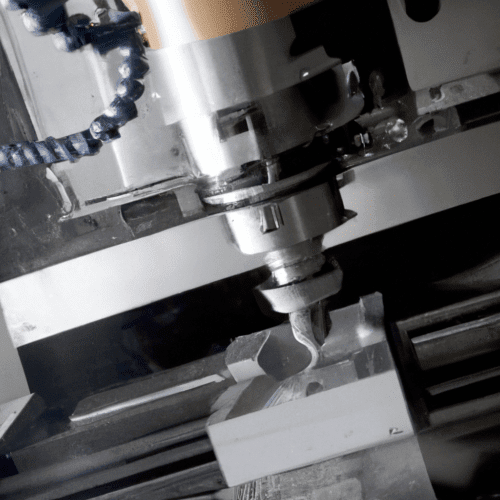

CNC (Computer Numerical Control) machines are automated tools used in industrial and commercial applications for machining parts and components with precision. CNC machines have revolutionized manufacturing processes, allowing for faster and more accurate production of parts and components than ever before. They also require fewer manual labor hours and are more reliable than traditional methods. However, they come with a number of potential drawbacks and associated costs that should be considered before investing in this type of machinery. One of the main advantages of CNC machines is their efficiency. CNC machines can be programmed to automatically perform a variety of operations on a single part, eliminating the need for manual labor. This makes them ideal for high-volume production runs, as they can produce identical parts with precision and accuracy. Furthermore, CNC machines require minimal operator intervention, ensuring that each part is machined to exact specifications. Nevertheless, CNC machines also have several potential drawbacks. One of the most important is their high cost. CNC machines are expensive to purchase and require additional investment in software and training.

Furthermore, the complexity of their programming can be difficult to master and they may require regular maintenance to ensure optimal performance. In addition, CNC machines can be prone to errors. These can occur due to programming mistakes or mechanical malfunctions, resulting in defective parts. The cost of reworking or replacing defective parts can be significant, so it’s important to have effective quality control processes in place to identify and address any issues promptly. Overall, CNC machines offer a range of advantages in terms of speed, accuracy, and efficiency. However, they also come with a number of potential drawbacks and associated costs that should be considered carefully before investing in this type of machinery.

What Factors Determine the Cost of a CNC Machine?

The cost of a CNC machine is determined by a number of factors. These include the type of machine, its size, accuracy, the number of axes, the materials used in its construction, and the complexity of its programming. The cost also depends on the speed and repeatability of the machine, as well as the range of features, such as tool changers, coolant systems, and dust collection systems. The cost of the software, maintenance, and training can also affect the overall cost of the machine. Finally, the cost of the machine may also be affected by the manufacturer, the type of control system used, and the availability of spare parts and support.

Comparing the Costs of Different Types of CNC Machines

CNC machines are becoming increasingly popular for a variety of industrial uses. CNC machines come in many different sizes and configurations, and the costs can vary significantly. Understanding the different types of CNC machines and their associated costs is important for making informed purchasing decisions. The most basic type of CNC machine is the vertical machining center (VMC). VMCs are generally smaller and less expensive than other CNC machines, making them ideal for smaller-scale projects. They are also relatively simple to operate and maintain, making them a good choice for beginners. VMCs range in price from around $15,000 to $100,000, depending on the size and features. The next type of CNC machine is the horizontal machining center (HMC). HMCs are generally larger and more expensive than VMCs, and they are best suited for more complex projects. HMCs typically range in price from around $50,000 to $500,000, depending on the size and features.

The third type of CNC machine is the multi-axis machine. Multi-axis machines are designed for complex projects that require precise movements along multiple axes. These machines are typically more expensive than VMCs and HMCs, ranging in price from around $100,000 to over $1 million. Finally, there are specialized CNC machines that are designed for specific tasks, such as engraving or 3D printing. These machines are usually the most expensive, with prices ranging from around $10,000 to over $1 million. In general, the cost of CNC machines depends on the type of machine, the size, and the features. Understanding the different types of CNC machines and their associated costs is important for making informed purchasing decisions.

Cost-Effective CNC Machines for Small Businesses: Finding the Right Machine for Your Budget

For small businesses, investing in CNC (computer numerical control) machines can be a great way to increase manufacturing speed and accuracy. CNC machines are computer-controlled cutting tools that can be programmed to perform a wide range of tasks, from cutting, drilling, and milling, to more complex operations such as threading and engraving. By investing in a CNC machine, businesses can save time and money by eliminating manual labor and streamlining production processes. The cost of CNC machines is one of the biggest deciding factors when it comes to investing in one. Fortunately, there are a range of CNC machines available to suit different budgets. Depending on the size and complexity of the job, businesses can choose from small desktop CNC machines to larger industrial-grade models. For businesses on a tight budget, the most cost-effective option is a desktop CNC machine. These machines are designed for small-scale operations and can be used for a variety of tasks, from engraving and drilling to cutting and milling. They are relatively small and compact, and don’t require a large space to operate.