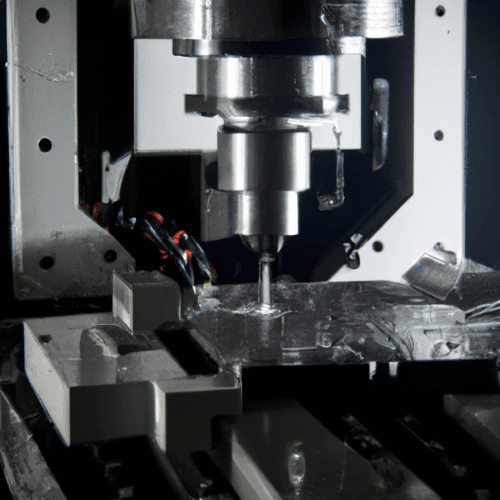

CNC (Computer Numerical Control) machines are automated tools that enable precision cutting, shaping, and drilling of materials. CNC machines are used in a wide range of industries, from automotive to aerospace. The best CNC machine depends on the application; for example, a CNC router is ideal for cutting and carving wood, while a CNC lathe is better suited for creating cylindrical parts. Additionally, CNC milling machines are typically used for machining metal parts. All CNC machines are equipped with a controller, which directs the movements of the cutting tool, as well as a computer to store and execute the instructions. CNC machines can be purchased in a variety of sizes, from desktop models to large industrial models. When selecting the right CNC machine, it is important to consider the material to be machined, the accuracy required, and the size of the parts to be produced.

An Overview of Features to Look for in the Best CNC Machines

CNC machines are cutting-edge tools used in a variety of industries for precision manufacturing. They are capable of producing complex components to exacting standards with a minimum of human intervention. To get the most out of these machines, it is important to choose the right machine for the job. Here is an overview of features to look for when choosing the best CNC machine. First, consider the size of the machine. CNC machines come in a variety of sizes and configurations. You need to make sure that the machine you choose is large enough to handle the job you need it to do. The size of the workpiece and the material you are working with will determine the size of the machine. Second, think about the type of material you will be working with. Different materials require different cutting tools and have different tolerances. Because of this, you need to make sure that the machine you choose is compatible with the materials you will be using. Third, consider the accuracy and precision of the machine.

CNC machines are designed to produce parts with exacting precision, so it is important to choose a machine that can produce the exact dimensions you require. Look for a machine with a high repeatability rate and check to see if it has any features that will help you achieve the desired accuracy. Fourth, look for a machine that is easy to use and maintain. Many CNC machines are complex and require specialized knowledge to operate. Make sure that the machine you choose is user-friendly and has a simple operating system. Also, make sure that the machine has easy maintenance requirements. Finally, consider the cost of the machine. CNC machines are expensive, so you need to make sure that you are getting the most for your money. Shop around and compare prices to get the best deal. These are just a few of the features to look for when choosing the best CNC machine. Taking the time to research your options and compare features will help you find the perfect machine for your needs.

Exploring the Pros and Cons of the Most Popular CNC Machines

CNC machines are automated tools used in manufacturing processes that enable the production of complex pieces with precision and speed. They are used in a variety of industries, including automotive, aerospace, medical, and industrial. The most popular CNC machines are milling machines, lathes, routers, and laser cutters. Each of these machines offers unique advantages and disadvantages. Milling machines are the most common type of CNC machine used in industrial settings. They are used to cut and shape material into precise shapes and sizes. The main advantages of milling machines include their high speed, accuracy, and repeatability. They are also relatively easy to operate and maintain. However, milling machines are limited in what materials they can cut and their size and weight often make them difficult to move around. Lathes are another type of CNC machine used in industrial settings. They are used to create cylindrical parts such as screws, bolts, and shafts. Lathes offer high accuracy and repeatability, as well as the ability to turn materials into complex shapes. However, they are limited in the types of materials they can turn and they are fairly large and heavy.

Routers are another type of CNC machine used in a variety of industrial settings. They are used to cut and shape materials into various shapes and sizes. Routers are relatively simple to use and maintain, and they offer high accuracy and repeatability. However, they are limited in the types of materials they can cut and their size and weight can make them difficult to move around. Laser cutters are the most advanced type of CNC machine. They are used to cut and shape materials into complex shapes with high precision. Laser cutters offer a high level of accuracy and repeatability and they can cut a wide variety of materials. However, they require a significant amount of power and they are expensive to purchase and maintain. Each type of CNC machine offers unique advantages and disadvantages, making them suitable for different types of applications. When selecting a CNC machine, it is important to consider the specific needs of the project and choose a machine that will best meet those needs.

A Guide to Choosing the Right CNC Machine for Your Workshop

Are you looking for a CNC machine for your workshop? Choosing the right machine is essential to ensuring smooth operations and successful projects. This guide will help you select the best CNC machine for your needs.

1. Determine Your Needs Before you shop around, it’s important to assess your needs. Identify the types of projects you plan to do with the CNC machine, as well as the materials you’ll be working with. This will help you determine the size and type of CNC machine you need.

2. Consider Your Budget Your budget should be the first thing you consider before making a purchase. CNC machines come in a variety of sizes and prices, so you’ll need to decide how much you’re willing to spend.

3. Research Your Options Once you know what kind of machine you need, it’s time to start researching your options. Read reviews and compare features to make sure you’re getting the best value for your money.

4. Talk to Experts If you’re unsure about which machine to choose, talk to experts in the field. They can help you make an informed decision that’s right for your needs.

5. Take a Test Drive Before making a final decision, ask if you can take a test drive of the CNC machine. This will give you an idea of how it works and if it’s the right fit for your workshop. By following these steps, you can make sure you choose the perfect CNC machine for your needs. With the right machine, you can enjoy efficient and successful projects.

Breaking Down the Different Types of CNC Machines for Beginners

CNC machines are essential tools for a variety of manufacturing processes. They can be used to produce components with extreme accuracy and precision, ensuring that all components meet exact specifications. For beginners, there are several different types of CNC machines to consider, each with its own unique capabilities and features. The first type of CNC machine is the Lathe. A Lathe is a machine that rotates a workpiece while a cutting tool is used to shape it. Lathes are used to create components with cylindrical symmetry, such as shafts, pulleys, and spindles. The second type of CNC machine is the Milling Machine. A Milling Machine is a machine that uses a rotating cutting tool to shape and contour a workpiece. Milling Machines are used to create components with complex shapes, such as slots and grooves. The third type of CNC machine is the Router.

A Router is a machine that uses a variety of cutting tools to cut and shape material. It is used for cutting and shaping a wide variety of materials, including wood, aluminum, and plastic. The fourth type of CNC machine is the EDM (electrical discharge machining). EDM is a machining process that uses electrical sparks to remove material from a workpiece. EDM is typically used to create complex shapes and cavities in hard materials. Finally, the fifth type of CNC machine is the Laser Cutter. A Laser Cutter is a machine that uses a high-powered laser beam to cut and shape materials. Laser Cutters are used to create intricate shapes, such as letters and logos. These five types of CNC machines are the main categories of CNC machines. Depending on the application, each type of machine can be used for a specific purpose. For beginners, it is important to understand the different types of CNC machines and how they can be used in the production process.

An Evaluation of the Price Points of the Best CNC Machines on the Market

CNC machines are becoming increasingly popular in the modern manufacturing industry. They provide a level of accuracy and precision that is not achievable with manual tools. However, when it comes to selecting a CNC machine, one of the most important considerations is the price point. Different CNC machines come with different price tags, and it is important to understand which models offer the most value for money. When it comes to price points, it is important to consider both the initial cost of the machine as well as the cost of maintenance and upkeep. Some machines may be more expensive upfront but offer better value in the long run due to lower maintenance costs. Additionally, some machines may come with a variety of features that may be beneficial for certain applications. It is important to evaluate each machine and decide which one offers the best value for the intended use. When it comes to the best CNC machines on the market, some of the most popular models are the Haas VF-2, the Okuma LB3000 EX.

1. The Haas VF-2 is a highly capable machine that offers a high level of accuracy and reliability at an affordable price point. The Okuma LB3000 EX is a high-performance machine that is capable of tackling complex tasks with ease. The Mori Seiki MV-40 is a versatile machine that is designed for a wide range of applications. In terms of price points, the Haas VF-2 is the most affordable of the three machines, with a starting price of around $50,

2. The Okuma LB3000 EX is slightly more expensive at around $60,000, while the Mori Seiki MV-40 has a starting price of around $80,

3. However, all three machines offer excellent value for money, as they are all capable of producing high-quality results. When it comes to CNC machines, there is no one-size-fits-all solution. Each machine has its own unique features and capabilities that make it suitable for certain applications. As such, it is important to evaluate the various price points and features of each machine to determine which one provides the best value for money. By doing this, it is possible to find the machine that best suits the intended use and provides the best value for money.