What is a punching machine?

A punching machine is a type of machine used to create holes in a variety of materials. It is typically used in industrial settings to create holes in metal, plastic, wood, and other materials. Punching machines are typically powered by either hydraulic or pneumatic pressure, and they use a variety of tools to create the desired hole. The most common type of punching machine is the turret punch press, which uses a series of rotating tools to create the desired hole. The tools used in a turret punch press can range from simple punches to more complex tools such as dies and formers. Punching machines can also be used to create a variety of other shapes, such as slots, notches, and embossed patterns. Punching machines are used in a variety of industries, including automotive, aerospace, and electronics.

What is a punching machine used for?

A punching machine is a type of machine used to create holes in a variety of materials. It is commonly used in industrial settings to create holes in sheet metal, plastic, and other materials. Punching machines are used in a variety of industries, including automotive, aerospace, and electronics. They are also used in the manufacturing of furniture, appliances, and other products. Punching machines are typically used to create holes in materials for the purpose of joining them together, such as in riveting, welding, and other joining processes. They can also be used to create decorative patterns in materials, such as in the creation of perforated metal sheets. Punching machines are available in a variety of sizes and configurations, and can be powered by either manual or electric motors.

What is also known as a punching machine?

A punching machine, also known as a punch press, is a type of machine used to shape metal by cutting, forming, or shearing it with a die. It works by using a ram to press a tool, called a punch, into the metal, which then cuts, forms, or shears the metal into the desired shape. Punching machines are used in a variety of industries, including automotive, aerospace, and electronics, to create components such as engine parts, aircraft parts, and circuit boards. Punching machines are also used in the manufacturing of furniture, appliances, and other consumer goods. Punching machines are available in a variety of sizes and configurations, and can be powered by either manual or automated systems.

What is a punch in machining?

A punch in machining is a tool used to create a hole in a workpiece. It is typically used in conjunction with a die, which is a tool used to shape the workpiece. The punch is inserted into the die and then struck with a hammer or press to create the hole. The punch is usually made of hardened steel and is available in a variety of shapes and sizes. The shape of the punch determines the shape of the hole that is created. Punching is a common machining process used in many industries, including automotive, aerospace, and medical. It is used to create holes in sheet metal, plastic, and other materials. Punching is a cost-effective and efficient way to create holes in a variety of materials.

Which type of machine uses a punching operation?

A punching operation is a type of machining process that uses a tool to create a hole in a workpiece. This type of operation is typically used to create holes in sheet metal, but can also be used to create holes in other materials such as plastics and wood. The tool used in a punching operation is typically a punch press, which is a type of machine that uses a die to shape the material. The punch press is usually operated by a hydraulic or mechanical system, and the die is typically made of hardened steel. The punch press is used to apply pressure to the material, which causes the material to deform and create a hole. The size and shape of the hole is determined by the shape of the die.

Punching operations are commonly used in the manufacturing of parts for a variety of industries, including automotive, aerospace, and electronics. The process is relatively fast and cost-effective, and can be used to create a variety of shapes and sizes of holes. Punching operations are also used to create slots, notches, and other features in a workpiece.

How many types of punching machines are there?

There are several different types of punching machines available on the market today. The most common type is the mechanical punch press, which uses a die to cut or shape metal or other materials. This type of machine is typically used for production runs of parts that require a high degree of accuracy and repeatability. Other types of punching machines include hydraulic presses, which use hydraulic pressure to punch holes in materials, and pneumatic presses, which use compressed air to punch holes. Laser cutting machines are also available, which use a laser beam to cut or shape materials. These machines are often used for more intricate designs or for cutting materials that are too thick for a mechanical punch press. Finally, there are also CNC punching machines, which are computer-controlled and can be programmed to produce complex shapes and patterns.

Is punching machine a simple machine?

A punching machine is a type of machine that is used to punch holes in various materials, such as paper, metal, plastic, and leather. It is considered a simple machine because it uses a single force to create a hole in the material. The force is usually applied by a lever or a crank, which is connected to a plunger that is used to punch the hole. The plunger is usually made of a hard material, such as steel, and is designed to be able to withstand the force of the lever or crank.

The punching machine is a simple machine because it uses a single force to create a hole in the material. This force is usually applied by a lever or a crank, which is connected to a plunger that is used to punch the hole. The plunger is usually made of a hard material, such as steel, and is designed to be able to withstand the force of the lever or crank. The plunger is then pushed into the material, creating a hole.

How does a turret punch work?

A turret punch is a type of machine tool used for punching holes in sheet metal. It is a specialized type of punch press that uses a rotating turret to hold multiple tools and perform multiple operations in a single setup. The turret punch is a versatile machine that can be used to create a variety of shapes and sizes of holes in sheet metal.

The turret punch works by using a rotating turret to hold multiple tools. The turret is mounted on a spindle and can be rotated to bring the desired tool into position. The turret is then locked in place and the tool is brought into contact with the sheet metal. The tool is then activated, either by a foot pedal or a hand lever, and the punch is driven through the sheet metal. The punch is then retracted and the turret is rotated to bring the next tool into position. This process is repeated until all the desired holes have been punched.

Who invented the punching machine?

The invention of the punching machine is credited to a man named Henry Maudslay, who was an English engineer and inventor. He is considered to be one of the most important figures in the Industrial Revolution. Maudslay was born in 1771 and began his career as an apprentice to a blacksmith. He quickly developed a reputation for his skill in metalworking and was eventually hired by Joseph Bramah, a famous inventor and locksmith.

Maudslay’s most famous invention was the punching machine, which he developed in 1806. The machine was designed to punch holes in metal plates, which was a difficult and time-consuming task before its invention. The machine was revolutionary in that it could punch holes in metal plates with great accuracy and speed. It was also the first machine to use a cam-operated mechanism, which allowed it to be operated by a single person.

What is a punching machine made of?

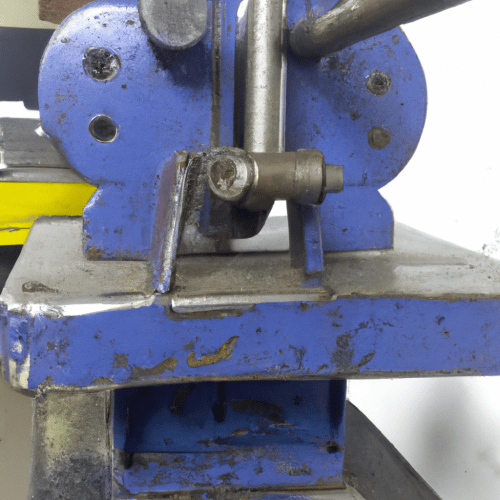

A punching machine is a type of machine tool used to shape metal by applying pressure to it. It typically consists of a base, a frame, a die, a punch, and a motor. The base is usually made of cast iron or steel and is designed to provide a stable platform for the machine. The frame is typically made of steel and is designed to hold the die and punch in place. The die is usually made of hardened steel and is designed to cut or shape the metal as the punch is pressed against it. The punch is typically made of hardened steel and is designed to press the metal against the die. The motor is usually an electric motor and is designed to provide the power to move the punch and die.