A machining tool is a device used to shape and cut materials such as metal, wood, plastic, or composites. Machining tools are typically powered by electricity, compressed air, or hydraulics, and are used in a variety of industrial applications. Machining tools can be used to create a variety of shapes and sizes, from simple holes to complex contours. They can also be used to create intricate patterns and designs. Common machining tools include lathes, milling machines, drill presses, saws, grinders, and routers. Each of these tools has its own unique set of capabilities and is used for different types of machining operations. For example, a lathe is used to shape and cut cylindrical objects, while a milling machine is used to shape and cut flat surfaces. A drill press is used to create holes, while a saw is used to cut shapes. Grinders are used to shape and finish surfaces, while routers are used to create intricate patterns and designs.

What is the tool in machining?

Machining is a manufacturing process in which a material is cut into a desired shape and size by a controlled material-removal process. The tool used in machining is a cutting tool, which is typically a rotary cutting tool such as a drill bit, end mill, or router bit. The cutting tool is held in a tool holder, which is then mounted in a machine such as a lathe, milling machine, or drill press. The cutting tool is then used to remove material from the workpiece, which is typically a piece of metal, plastic, or wood. The cutting tool is moved in a specific pattern to create the desired shape and size of the workpiece. The cutting tool is also used to create holes, slots, and other features in the workpiece. The cutting tool is typically made of high-speed steel or carbide, and is designed to withstand the high temperatures and forces generated during the machining process.

What are examples of machine tools?

Machine tools are tools used in the manufacturing industry to shape and cut materials such as metal, wood, and plastic. Examples of machine tools include lathes, milling machines, drill presses, grinding machines, saws, sanders, and routers.

Lathes are used to shape materials by spinning them and cutting them with a cutting tool. Lathes can be used to create a variety of shapes, including cylinders, cones, and irregular shapes. Lathes are also used to create threads on the outside of a workpiece.

Milling machines are used to shape materials by cutting them with a rotating cutting tool. Milling machines can be used to create a variety of shapes, including flat surfaces, curved surfaces, and irregular shapes.

Drill presses are used to drill holes into materials. Drill presses can be used to create a variety of hole sizes and shapes, including round, square, and hexagonal holes.

What is machinery and tools?

Machinery and tools are machines and devices that are used to perform a specific task or set of tasks. They are used to make work easier and more efficient, and can range from simple hand tools to complex industrial machines. Machinery and tools are used in a variety of industries, including manufacturing, construction, agriculture, and transportation. They are used to cut, shape, and assemble materials, as well as to move, lift, and transport them. Machinery and tools can be powered by electricity, gasoline, diesel, or other sources of energy. They can be operated manually or by computer-controlled systems. Examples of machinery and tools include saws, drills, lathes, presses, grinders, and welding machines.

What are the functions of machine tool?

A machine tool is a machine for shaping or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformation. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool is controlled or constrained by the machine to at least some extent.

The primary functions of machine tools are to shape and form metal and other materials into desired shapes and sizes. This is done by cutting, drilling, grinding, and other machining processes. Machine tools are also used to produce parts with precise dimensions and tolerances. They are also used to produce parts with complex shapes and features.

Machine tools are used in a variety of industries, including automotive, aerospace, medical, and consumer products.

What is basic machining?

Basic machining is a manufacturing process that involves the use of tools to shape and cut materials into desired shapes and sizes. It is a subtractive process, meaning that material is removed from the workpiece in order to create the desired shape. Basic machining is used in a variety of industries, including automotive, aerospace, medical, and consumer products.

The most common type of basic machining is milling, which involves the use of a rotating cutting tool to remove material from the workpiece. The cutting tool is usually a milling cutter, which is a type of rotary cutting tool with multiple cutting edges. The cutting tool is moved along the surface of the workpiece in a linear or circular motion, removing material as it goes. Other types of basic machining include drilling, turning, and grinding.

Drilling is a process in which a hole is created in the workpiece using a rotating drill bit. Turning is a process in which a rotating cutting tool is used to shape the outside of the workpiece.

How many types of machine tools are there?

There are many different types of machine tools, and the exact number depends on how they are classified. Generally, machine tools are divided into two main categories: metal cutting and metal forming. Metal cutting tools are used to cut and shape metal into desired shapes and sizes. Examples of metal cutting tools include lathes, milling machines, drill presses, and grinding machines. Metal forming tools are used to form metal into desired shapes and sizes. Examples of metal forming tools include presses, forging machines, and rolling machines.

Within these two main categories, there are several subcategories of machine tools. For example, lathes can be further divided into engine lathes, turret lathes, and special purpose lathes. Milling machines can be further divided into vertical milling machines, horizontal milling machines, and universal milling machines. Drill presses can be further divided into radial drill presses, gang drill presses, and multiple spindle drill presses. Grinding machines can be further divided into cylindrical grinders, surface grinders, and tool and cutter grinders.

What is machine tool structure?

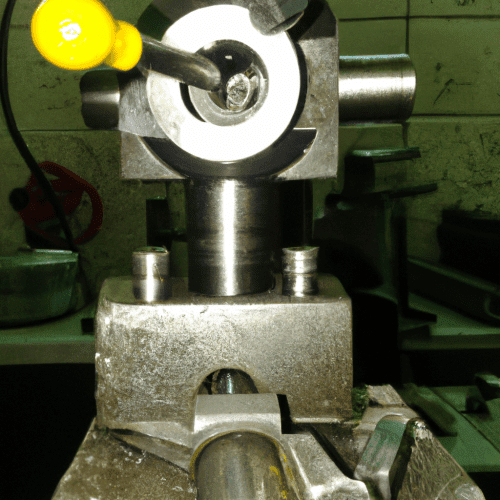

Machine tool structure is the physical arrangement of the components that make up a machine tool. It is the framework that holds the various components together and allows them to interact with each other. The structure of a machine tool is typically composed of a base, a bed, a spindle, a headstock, a tailstock, and a tool holder. The base is the foundation of the machine tool and provides the necessary support for the other components. The bed is the platform on which the spindle and other components are mounted. The spindle is the rotating shaft that drives the cutting tool. The headstock is the part of the machine tool that holds the spindle and the cutting tool. The tailstock is the part of the machine tool that holds the workpiece in place. The tool holder is the part of the machine tool that holds the cutting tool in place.

The structure of a machine tool is designed to provide the necessary support and stability for the components to function properly.

What was the first machine tool?

The first machine tool was the lathe, which was invented in ancient Egypt around 1300 BC. The lathe was used to shape wood and metal into various shapes and sizes. It was powered by a bow drill, which was operated by a person turning a handle. The lathe was used to create objects such as furniture, tools, and weapons.

The first machine tool to use a power source was the milling machine, which was invented in the early 19th century. This machine used a rotating cutter to shape metal into various shapes and sizes. It was powered by a steam engine, which was operated by a person turning a crank. The milling machine was used to create objects such as gears, screws, and other machine parts.

The first machine tool to use electricity was the drill press, which was invented in the late 19th century. This machine used a rotating drill bit to shape metal into various shapes and sizes. It was powered by an electric motor, which was operated by a person turning a switch.

What is machining and types?

Machining is a manufacturing process in which parts are cut from a raw material using a variety of tools. It is a subtractive process, meaning that material is removed from the workpiece to create the desired shape. Machining is used to create parts with complex shapes and features that would be difficult or impossible to create using other manufacturing processes.

There are several types of machining processes, each with its own advantages and disadvantages. The most common types of machining processes are turning, milling, drilling, grinding, and sawing.

Turning is a machining process in which a cutting tool is used to remove material from a rotating workpiece. The cutting tool is typically a single-point cutting tool, such as a lathe tool or a drill bit. The workpiece is rotated against the cutting tool, and material is removed from the workpiece in the form of chips. Turning is used to create cylindrical parts with a uniform diameter.

Milling is a machining process in which a rotating multi-point cutting tool is used to remove material from a workpiece.

How are machine tools classified?

Machine tools are classified according to their function, the type of material they are used to process, and the type of motion they use.

Functionally, machine tools are divided into three main categories: cutting, forming, and joining. Cutting tools are used to cut material into a desired shape or size, such as a drill bit or a lathe. Forming tools are used to shape material, such as a press or a milling machine. Joining tools are used to join two pieces of material together, such as a welding machine or a riveting machine.

The type of material that a machine tool is used to process is also a factor in its classification. For example, a lathe is used to process metal, while a woodworking machine is used to process wood.

The type of motion used by a machine tool is also a factor in its classification. Machine tools can be classified as either rotary or linear. Rotary tools use a rotating motion, such as a drill or a lathe.