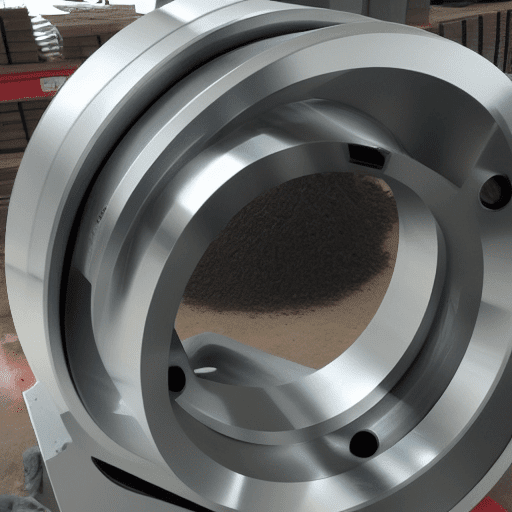

Yes, you can CNC aluminum. CNC stands for Computer Numerical Control, and it is a process that uses computer-controlled machines to shape and cut materials. Aluminum is a popular material to use with CNC machines because it is lightweight, strong, and easy to work with. CNC machines can be used to cut, drill, mill, and shape aluminum into a variety of shapes and sizes. The process begins by creating a 3D model of the desired shape or design in a CAD (Computer Aided Design) program. This model is then converted into a set of instructions for the CNC machine, which is programmed to cut the aluminum according to the instructions.

The CNC machine then uses a variety of cutting tools, such as end mills, drills, and routers, to cut the aluminum into the desired shape. The cutting tools are usually made of high-speed steel or carbide, and they are designed to cut aluminum quickly and accurately. After the aluminum is cut, it is then polished and finished to give it a smooth, professional look. CNC machining is a great way to create custom parts and components out of aluminum, and it is often used in the aerospace, automotive, and medical industries.

Is CNC Aluminium strong?

CNC Aluminium is a strong material, but its strength depends on the alloy used. Aluminium alloys are generally divided into two categories: wrought alloys and cast alloys. Wrought alloys are stronger than cast alloys, and are often used in CNC machining. The strength of a particular alloy is determined by its composition, which includes elements such as copper, magnesium, silicon, and zinc. The strength of an alloy is also affected by the heat treatment it undergoes. Heat treatment can increase the strength of an alloy by changing its microstructure. For example, an alloy that is heat treated to a higher temperature will have a higher strength than an alloy that is heat treated to a lower temperature. In general, CNC Aluminium is strong and can be used for a variety of applications, such as aerospace components, automotive parts, and medical devices.

What type of cutter is used for milling aluminum?

Milling aluminum requires a specific type of cutter to ensure that the material is cut properly and efficiently. The most common type of cutter used for milling aluminum is an end mill. End mills are designed with flutes that spiral around the cutting edge, allowing for efficient chip removal and a smooth finish. End mills are available in a variety of sizes and shapes, including square, ball, and corner radius, and can be used for a variety of operations, including face milling, shoulder milling, and slotting. Additionally, end mills can be used for both roughing and finishing operations. When selecting an end mill for milling aluminum, it is important to consider the material’s hardness, the depth of the cut, and the desired finish. For example, a high-speed steel end mill is best suited for softer aluminum alloys, while a carbide end mill is better suited for harder aluminum alloys. Additionally, a coated end mill is recommended for aluminum alloys that are prone to galling or welding.

Can you machine aluminum with a CNC router?

Yes, you can machine aluminum with a CNC router. CNC routers are computer-controlled machines that are used to cut and shape materials such as wood, plastic, and metal. Aluminum is a popular material to machine with a CNC router because it is lightweight, strong, and corrosion-resistant. When machining aluminum with a CNC router, it is important to use the correct cutting tools and speeds to ensure a quality finish. The cutting tools should be made of high-speed steel or carbide and should be sharpened regularly. The cutting speed should be adjusted based on the material being machined and the type of tool being used. Additionally, the feed rate should be adjusted to ensure that the cutting tool does not become overloaded. It is also important to use a lubricant when machining aluminum to reduce friction and heat buildup. Finally, it is important to use the correct cutting parameters to ensure that the aluminum is machined correctly and that the finished product meets the desired specifications.

What kind of aluminum is used for CNC?

Aluminum is a popular material for CNC machining because of its low cost, light weight, and machinability. The most common type of aluminum used for CNC machining is 6061 aluminum alloy. This alloy is a precipitation-hardened aluminum that is heat-treated and strengthened. It is one of the most versatile aluminum alloys available and is often used for applications that require good corrosion resistance, weldability, and moderate strength. It is also easy to machine and can be anodized for a variety of colors. Other aluminum alloys that are commonly used for CNC machining include 2024, 7075, and 5052. 2024 is a high-strength aluminum alloy that is often used for aerospace applications. 7075 is a high-strength aluminum alloy that is often used for structural applications. 5052 is a medium-strength aluminum alloy that is often used for sheet metal applications. Each of these aluminum alloys has its own unique properties and is best suited for specific applications.

What metals can CNC cut?

CNC (Computer Numerical Control) cutting is a process used to cut a variety of materials, including metals. The type of metal that can be cut with a CNC machine depends on the type of machine being used. Generally, CNC machines are capable of cutting a wide range of metals, including aluminum, brass, copper, steel, stainless steel, and titanium.

Aluminum is a lightweight metal that is often used in the aerospace and automotive industries. It is relatively easy to cut with a CNC machine, and it is often used to create parts for aircraft, cars, and other vehicles.

Brass is a metal alloy made up of copper and zinc. It is often used in the manufacturing of musical instruments, plumbing fixtures, and decorative items. Brass is relatively easy to cut with a CNC machine, and it is often used to create intricate parts and components.

Copper is a soft metal that is often used in the electrical and plumbing industries. It is relatively easy to cut with a CNC machine, and it is often used to create electrical components and plumbing fixtures.

Steel is a strong metal that is often used in the construction and automotive industries. It is relatively difficult to cut with a CNC machine, and it is often used to create structural components and parts for cars and other vehicles.

Stainless steel is a strong metal that is often used in the food and medical industries. It is relatively difficult to cut with a CNC machine, and it is often used to create components for food processing equipment and medical devices.

Titanium is a strong metal that is often used in the aerospace and medical industries. It is relatively difficult to cut with a CNC machine, and it is often used to create components for aircraft and medical implants.

In conclusion, CNC machines are capable of cutting a wide range of metals, including aluminum, brass, copper, steel, stainless steel, and titanium. The type of metal that can be cut with a CNC machine depends on the type of machine being used.

How much does CNC milling cost?

The cost of CNC milling depends on a variety of factors, including the size and complexity of the part being machined, the material being used, the number of parts being produced, and the type of CNC milling machine being used. Generally speaking, CNC milling can range from a few hundred dollars for a simple part to tens of thousands of dollars for a complex part. The cost of CNC milling also depends on the type of machining being done, such as 3-axis, 4-axis, or 5-axis machining. 3-axis machining is the most basic type of CNC milling and is typically the least expensive, while 5-axis machining is the most complex and is usually the most expensive. Additionally, the cost of CNC milling can be affected by the type of material being used, as some materials are more expensive than others. For example, aluminum is typically less expensive than stainless steel, and titanium is usually more expensive than both.

The cost of CNC milling also depends on the number of parts being produced. If a customer is looking to produce a large number of parts, the cost per part will usually be lower than if they are looking to produce a small number of parts. Additionally, the cost of CNC milling can be affected by the type of CNC milling machine being used. Some CNC milling machines are more expensive than others, and the cost of the machine can be a significant factor in the overall cost of CNC milling.

In conclusion, the cost of CNC milling can vary greatly depending on the size and complexity of the part being machined, the material being used, the number of parts being produced, and the type of CNC milling machine being used. Generally speaking, CNC milling can range from a few hundred dollars for a simple part to tens of thousands of dollars for a complex part.

Can you CNC metal?

Yes, it is possible to CNC metal. CNC stands for Computer Numerical Control, and it is a process that uses computer-controlled machines to shape and cut materials. CNC machines are used to cut and shape a variety of materials, including metal. The process involves using a computer to control the machine’s movements, which are then used to cut and shape the metal.

The CNC process is used in a variety of industries, including automotive, aerospace, and medical. It is used to create parts for cars, airplanes, and medical devices. The process is also used to create custom parts for a variety of applications.

The CNC process is relatively simple. First, a CAD (Computer Aided Design) file is created. This file contains the design of the part that needs to be cut or shaped. The CAD file is then loaded into the CNC machine, which is programmed to cut and shape the metal according to the design. The CNC machine then uses a variety of tools, such as drills, saws, and routers, to cut and shape the metal.

The CNC process is highly accurate and can be used to create complex shapes and parts. It is also relatively fast, allowing for quick turnaround times. Additionally, CNC machines are relatively easy to use and require minimal setup time.

Overall, CNC machines are a great way to cut and shape metal. They are accurate, fast, and easy to use, making them a great choice for a variety of applications.

What can a CNC cut?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that is used to cut and shape a variety of materials. CNC machines are used in a wide range of industries, from aerospace and automotive to medical and consumer products. CNC machines are capable of cutting a variety of materials, including metals, plastics, composites, wood, and foam.

CNC machines are used to cut parts to precise dimensions and shapes. They can be used to cut intricate shapes, such as those found in medical implants, or to cut large parts, such as those used in the aerospace industry. CNC machines are also used to cut complex shapes, such as those found in automotive parts.

CNC machines are capable of cutting a variety of materials, including aluminum, steel, brass, copper, titanium, and stainless steel. They can also cut a variety of plastics, such as ABS, polycarbonate, and nylon. CNC machines can also cut wood, composites, and foam.

CNC machines are used to cut parts to precise dimensions and shapes. They can be used to cut intricate shapes, such as those found in medical implants, or to cut large parts, such as those used in the aerospace industry. CNC machines are also used to cut complex shapes, such as those found in automotive parts.

CNC machines are also used to create molds and dies for injection molding and die casting. CNC machines are used to create molds for a variety of materials, including plastics, metals, and composites. CNC machines are also used to create dies for die casting, which is a process used to create metal parts.

CNC machines are also used to create engravings and other decorative features on a variety of materials. CNC machines are used to engrave logos, text, and other designs on metal, plastic, and wood. CNC machines are also used to create decorative features on jewelry and other items.

In summary, CNC machines are capable of cutting a variety of materials, including metals, plastics, composites, wood, and foam. They can be used to cut intricate shapes, large parts, and complex

How hard is it to machine aluminum?

Machining aluminum can be a difficult process, depending on the type of aluminum being machined and the complexity of the part being machined. Aluminum is a soft metal, which makes it easier to machine than harder metals such as steel. However, aluminum is also very ductile, meaning it can deform easily when machined. This can make it difficult to achieve precise tolerances and surface finishes. Additionally, aluminum is prone to work hardening, which can cause it to become more difficult to machine as machining progresses.

Aluminum also has a tendency to stick to the cutting tool, which can cause the tool to wear out quickly and require frequent replacement. This can be especially problematic when machining intricate parts with tight tolerances. Additionally, aluminum is prone to thermal expansion, which can cause parts to warp or distort when machined. This can make it difficult to achieve precise dimensions and surface finishes.

Overall, machining aluminum can be a difficult process, but with the right tools and techniques, it can be done successfully. It is important to use the right cutting tools and speeds, as well as coolant to reduce heat buildup and work hardening. Additionally, it is important to use the right cutting parameters and techniques to ensure that the parts are machined accurately and with the desired surface finish.

Is aluminum easier to machine than steel?

Aluminum is generally considered to be easier to machine than steel. This is because aluminum is a softer metal than steel, which makes it easier to cut and shape. Aluminum is also more malleable than steel, meaning it can be bent and formed into different shapes without breaking. Additionally, aluminum has a lower melting point than steel, which makes it easier to work with when machining.

When machining aluminum, it is important to use the right tools and techniques. Aluminum is more prone to heat buildup than steel, so it is important to use cutting tools that are designed for aluminum and to use coolant to keep the temperature down. Additionally, aluminum is more prone to chipping and tearing than steel, so it is important to use the correct cutting speeds and feeds to avoid these issues.

Overall, aluminum is generally considered to be easier to machine than steel due to its softer nature and lower melting point. However, it is important to use the right tools and techniques when machining aluminum to ensure a successful outcome.