A CNC turn mill machining centre is a type of computer numerical control (CNC) machine that combines the functions of a lathe and a milling machine. It is capable of performing multiple operations such as turning, milling, drilling, tapping, and boring. The three main operations of a CNC turn mill machining centre are:

1. Turning: This is the process of rotating a workpiece on a spindle and cutting it with a cutting tool. The cutting tool is usually a single-point cutting tool, but can also be a multi-point cutting tool. The cutting tool is held in a tool holder and is moved along the workpiece in a linear direction. The cutting tool is then rotated to cut the material.

2. Milling: This is the process of using a rotating cutting tool to remove material from the workpiece. The cutting tool is usually a multi-point cutting tool, such as an end mill or a face mill. The cutting tool is held in a tool holder and is moved along the workpiece in a linear direction. The cutting tool is then rotated to cut the material.

3. Drilling: This is the process of using a rotating cutting tool to create a hole in the workpiece. The cutting tool is usually a single-point cutting tool, such as a drill bit. The cutting tool is held in a tool holder and is moved along the workpiece in a linear direction. The cutting tool is then rotated to cut the material.

What are 3 types of CNC machines?

CNC machines are computer-controlled machines used for cutting, drilling, grinding, and other manufacturing processes. There are three main types of CNC machines: milling machines, lathes, and routers.

Milling machines are used to cut and shape metal and other materials. They use a rotating cutting tool to remove material from the workpiece. The cutting tool is usually a drill bit, end mill, or face mill. Milling machines can be used to create complex shapes and contours, as well as to drill holes and create slots.

Lathes are used to shape metal and other materials by rotating them against a cutting tool. The cutting tool is usually a single-point cutting tool, such as a drill bit, chisel, or reamer. Lathes can be used to create complex shapes and contours, as well as to drill holes and create slots.

What can you make with a 3 axis CNC mill?

A 3 axis CNC mill is a type of machine tool that uses computer numerical control (CNC) to automate the machining process. It is capable of cutting and shaping a variety of materials, including metal, wood, plastic, and composites. With a 3 axis CNC mill, you can create a wide range of products, from simple parts to complex components.

One of the most common uses for a 3 axis CNC mill is to create parts for industrial machinery. This includes components for engines, pumps, valves, and other mechanical systems. It can also be used to create parts for consumer products, such as toys, furniture, and electronics.

In addition to creating parts, a 3 axis CNC mill can also be used to create molds and dies for injection molding and die casting. This is a great way to produce large quantities of parts quickly and accurately.

Another popular use for a 3 axis CNC mill is to create custom parts for prototyping and product development. This is especially useful for creating parts that are difficult to produce with traditional machining methods.

How many operations does a CNC machine have?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. The number of operations a CNC machine can perform depends on the type of machine and the complexity of the program. Generally, CNC machines can perform a variety of operations, including drilling, milling, turning, and grinding. Some CNC machines are even capable of performing more complex operations such as welding, cutting, and engraving. The number of operations a CNC machine can perform is limited only by the complexity of the program and the capabilities of the machine.

For example, a CNC machine with a more advanced program and a larger tool set may be able to perform more operations than a simpler machine with a more basic program. Additionally, some CNC machines are capable of performing multiple operations at once, such as drilling and milling simultaneously. Ultimately, the number of operations a CNC machine can perform is determined by the capabilities of the machine and the complexity of the program.

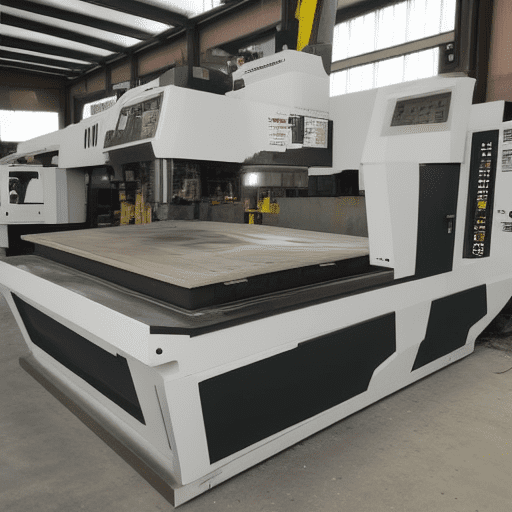

What is a 3 axis CNC router?

A 3 axis CNC router is a computer numerical control (CNC) machine that is used to cut and shape materials such as wood, plastic, and metal. It is a type of CNC machine that is capable of moving in three axes: the X-axis, Y-axis, and Z-axis. The X-axis is the left-right movement, the Y-axis is the forward-backward movement, and the Z-axis is the up-down movement. The 3 axis CNC router is used to cut and shape materials with precision and accuracy. It is commonly used in the manufacturing industry for creating parts and components for products. It is also used in the woodworking industry for creating furniture, cabinets, and other wood products. The 3 axis CNC router is a versatile machine that can be used for a variety of applications. It is capable of cutting and shaping materials with precision and accuracy, making it an ideal choice for many industries.

What are different types of milling operations?

Milling operations are a type of machining process that uses a rotating cutting tool to remove material from a workpiece. The cutting tool can be a single-point cutting tool, such as a drill bit, or a multi-point cutting tool, such as a milling cutter. There are several different types of milling operations, each of which produces a different result.

One type of milling operation is face milling, which is used to create flat surfaces on a workpiece. This is done by using a cutter with multiple cutting edges that is mounted on a spindle and fed into the workpiece. The cutter rotates and moves along the surface of the workpiece, removing material as it goes.

Another type of milling operation is end milling, which is used to create a flat surface on the end of a workpiece. This is done by using a cutter with multiple cutting edges that is mounted on a spindle and fed into the end of the workpiece. The cutter rotates and moves along the end of the workpiece, removing material as it goes.

What is CNC lathe machine operation?

CNC lathe machine operation is a process of machining a workpiece on a lathe machine using computer numerical control (CNC). CNC lathe machines are automated lathes that are programmed to perform specific operations on a workpiece. The CNC lathe machine operator is responsible for programming the machine to perform the desired operations, setting up the machine, and monitoring the machine during the machining process.

The CNC lathe machine operator must be familiar with the machine’s programming language and the various operations that can be performed on the machine. The operator must also be familiar with the various cutting tools and materials that can be used on the machine. The operator must also be able to read and interpret blueprints and drawings to ensure that the machine is set up correctly and that the desired operations are performed correctly.

Once the machine is set up, the operator will enter the program into the machine’s control panel. The program will tell the machine what operations to perform on the workpiece. The operator will then monitor the machine as it performs the operations.