The world of jewelry making has evolved over the years, from handcrafting to the introduction of advanced machinery and technology. One such advancement is the use of Computer Numerical Control (CNC) machinery in jewelry design and creation. In this beginner’s guide, we’ll delve into how CNC machinery is revolutionizing the jewelry industry and provide a closer look at CNC milling machines and CNC routers.

CNC Machinery in Jewelry Making

CNC machinery is at the forefront of modern jewelry making, providing precision, repeatability, and efficiency. Gone are the days when jewelers had to solely rely on their handcrafting skills for intricate designs. With CNC machinery:

- Precision and Accuracy: Designs can be replicated to perfection, ensuring every piece maintains the same quality and design.

- Intricate Designs: CNC allows for the creation of designs that would be incredibly challenging to craft by hand.

- Time Efficiency: Production time is significantly reduced, especially for large orders or intricate designs.

CNC Milling Machine in Jewelry Making

A CNC milling machine, commonly just called a CNC mill, is a specific type of CNC machinery tailored to remove material from a workpiece.

- Functionality: CNC mills are designed to transform a solid block of material, such as silver or gold, into a finely crafted jewelry piece. They achieve this by spinning a cutting tool at high speed to remove unwanted material.

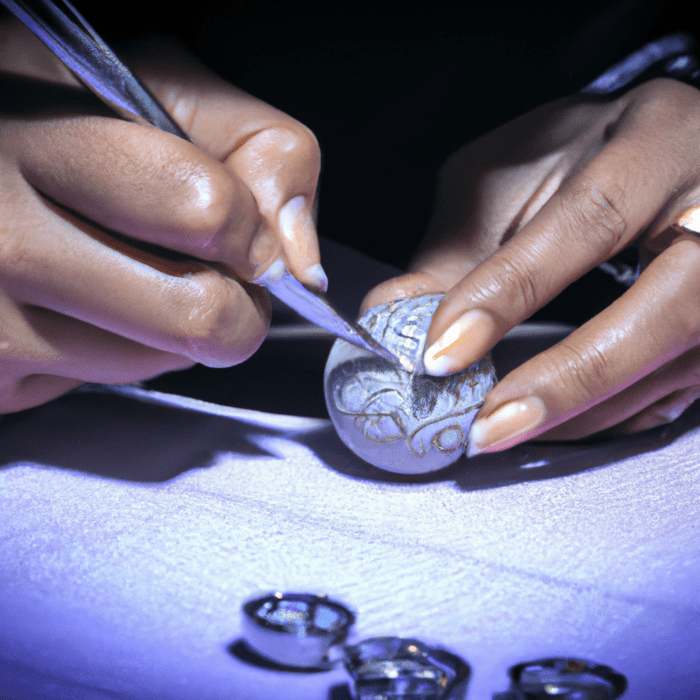

- Detailing and Engraving: These machines can achieve highly detailed engravings, which can add personalized touches or intricate patterns to jewelry pieces.

- Types of Materials: While metals like gold, silver, and platinum are common, CNC mills can also work with other materials like gemstones, provided the right settings and tools are used.

CNC Routers in Jewelry Making

While CNC milling machines focus on engraving and cutting from solid blocks, CNC routers are designed more for the shaping and hollowing out of materials.

- Versatility: CNC routers can be used for a variety of tasks in jewelry making, including hollowing out pieces, shaping gemstones, and even cutting larger jewelry components.

- Speed: Routers often work at higher speeds than milling machines, making them excellent for tasks that don’t require as much intricate detail but need to be done quickly.

- Materials: Routers are versatile in the types of materials they can handle. Beyond metals, they can also shape materials like wood and plastics, which are sometimes incorporated into unique jewelry pieces.

CNC Engraving Machine in Jewelry Making

Another jewel in the crown of CNC machinery for jewelry making is the CNC engraving machine. Unlike milling machines and routers which are generally used for larger scale operations, engraving machines focus on finer details.

- Precision Engravings: CNC engraving machines are ideal for producing intricate patterns, inscriptions, and detailed artwork on jewelry pieces. With laser-sharp precision, they etch designs onto surfaces, bringing out the jeweler’s vision to life.

- Multiple Materials: These machines aren’t limited to just metals. They can engrave on gemstones, pearls, and other jewelry materials, broadening the design possibilities.

- Personalization: They’re a favorite for personalizing jewelry, whether it’s adding a special date, name, or message, making the piece even more special.

CNC Lathes in Jewelry Making

A CNC lathe, unlike a milling machine which rotates the cutting tool, rotates the workpiece itself. This rotation, combined with the precision movement of tools, allows jewelers to craft symmetrical pieces with unparalleled precision.

- Symmetrical Designs: Perfect for creating symmetrical jewelry pieces, such as rings or bangles, where uniformity around an axis is required.

- Polishing and Finishing: Beyond cutting and shaping, CNC lathes can also be used for the polishing phase, providing a smooth, finished look to the jewelry.

- Material Conservation: CNC lathes often lead to less wastage of material compared to manual lathing since the precision ensures only the necessary amount of material is removed.

Benefits of CNC Machining for Jewelry

The adoption of CNC machinery in the jewelry-making industry has not just been a trend but a game-changer. Here are some of the key benefits:

- Consistency: One of the major advantages is the ability to produce multiple pieces with the exact same design, dimensions, and quality. This consistency is invaluable, especially for large orders or branded jewelry lines.

- Efficiency: With automated processes, production times are cut significantly. What might take hours or even days by hand can be accomplished in a fraction of the time.

- Complexity and Detail: Designs that were once deemed too intricate or time-consuming to be made by hand are now possible. From elaborate patterns to minute details, CNC machines allow jewelers to push the boundaries of design.

- Reduced Waste: Precision means there’s a reduction in material wastage. When working with expensive materials like gold or gemstones, this can lead to significant cost savings.

- Safety: CNC machines also reduce the risks associated with manual handling, especially when working with sharp tools or toxic materials.

- Scalability: For businesses, CNC machinery can be a boon. As the demand for a particular jewelry piece rises, CNC machines can easily ramp up production without compromising on quality.