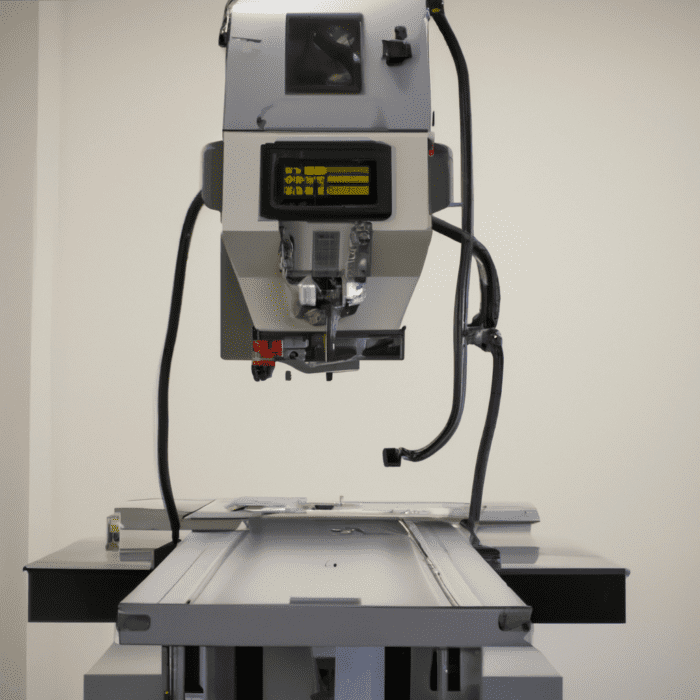

CNC machinery has revolutionized the manufacturing and woodworking industry, bringing unparalleled precision, speed, and consistency to various tasks. Among the popular CNC machines, the 4×8 CNC router stands out due to its optimal size and versatility. In this article, we’ll delve deep into what makes a 4×8 CNC router tick, the differences between a CNC router and a CNC mill, and the must-have features for the best routers.

What is a 4X8 CNC Router?

A 4×8 CNC router refers to a computer numerical control (CNC) machine designed to cut, carve, drill, or mill materials like wood, plastic, and soft metals on a worktable measuring 4 feet by 8 feet. Its name is derived directly from the size of the bed it can accommodate. These routers are particularly popular among woodworkers and furniture makers due to the following advantages:

- Versatility: Suitable for a wide range of applications from cabinetry to sign-making.

- Size: The 4×8 bed size is large enough for standard sheet materials, making it efficient for batch production.

- Precision: Modern CNC routers offer precise cutting with minimal waste and errors.

CNC Router vs. CNC Mill: Spotting the Difference

At first glance, CNC routers and CNC mills might seem quite similar. They both operate under computer control, move in multiple axes, and are used to machine materials. However, the differences are pronounced in terms of their construction, applications, and the materials they handle:

- Purpose:

- CNC Router: Primarily used for cutting softer materials such as wood, plastics, and foam. They excel in tasks like engraving, detailed carving, and producing intricate designs.

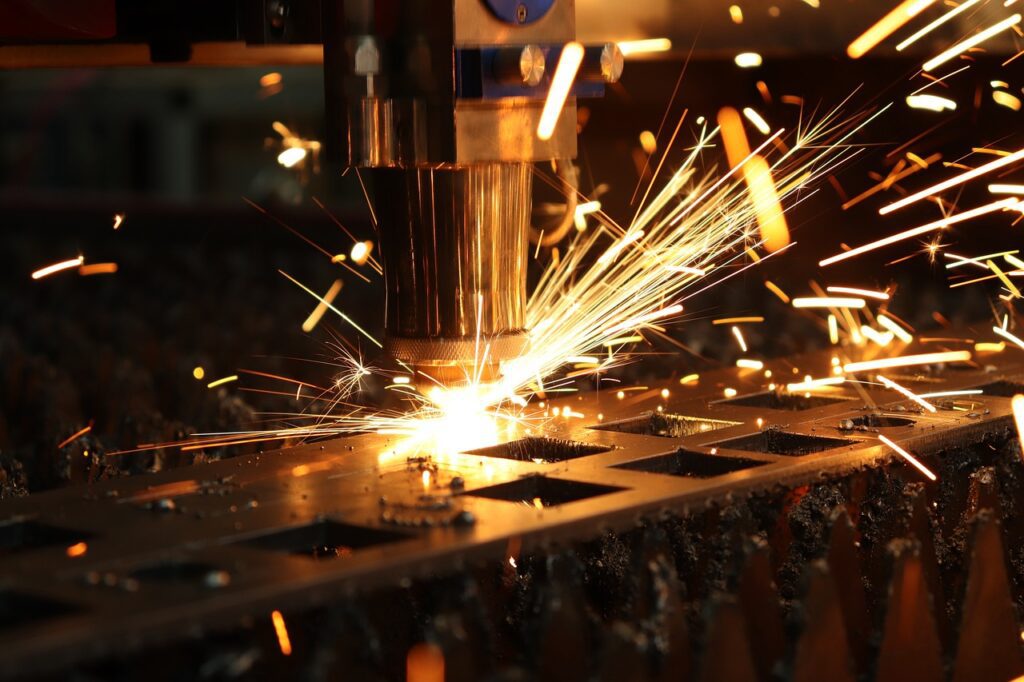

- CNC Mill: Designed for harder materials like metals. They can handle tasks like drilling, tapping, and contouring.

- Construction:

- CNC Router: Typically lighter in construction with a gantry design, allowing for faster movement and operation.

- CNC Mill: Built robustly to handle tougher materials, and the spindle moves over a stationary table.

- Spindle Speed:

- CNC Router: Generally has higher spindle speeds, which is ideal for the fast cutting of softer materials.

- CNC Mill: Operates at slower speeds but with more torque, making it suitable for milling harder substances.

- Tooling:

- CNC Router: Utilizes larger diameter tooling for broad strokes.

- CNC Mill: Employs more specialized and precise tooling for detailed operations.

- Cost:

- CNC Router: Typically more affordable, making it a popular choice for hobbyists and small businesses.

- CNC Mill: Due to their rugged construction and capabilities, they tend to be more expensive.

Features Every Best 4×8 CNC Router Must Possess

For a CNC router to stand out from the rest, it should possess the following features:

- High Precision Drive System: Look for routers with ball screw or rack and pinion drive systems for accuracy.

- Powerful Spindle: A high-quality, powerful spindle ensures efficient and smooth operations.

- Robust Construction: A sturdy frame reduces vibrations, ensuring cleaner cuts.

- User-Friendly Software: Intuitive software interface is key for designing, controlling, and monitoring tasks.

- Safety Features: Features like emergency stop buttons, dust collection systems, and shield guards are essential for operator safety.

- Compatibility: The ability to support a variety of file formats and integrate with popular design software.

- Expandability: Consider routers that allow for upgrades or expansions, such as tool changers or additional modules.

Which Industries Use CNC Routers?

CNC routers have found applications in a plethora of industries, driven by their versatility, precision, and efficiency.

Woodworking: This is perhaps the most obvious industry. From furniture design to intricate wooden art, the precision and repeatability of CNC routers make them invaluable for tasks like cabinetry, molding, and decorative designs.

Sign Making: The ability of CNC routers to carve intricate patterns and shapes in various materials is a boon for the sign-making industry. Whether it’s creating large commercial signs or intricate displays with depth and detail, CNC routers deliver where traditional methods falter.

Aerospace and Automobiles: While CNC mills are more popular in these sectors due to the need to work with metals, CNC routers play a role in the manufacturing of specific components, especially those made from composite materials or plastics.

Stone and Metal Engraving: Some high-end CNC routers are designed to handle harder materials like stone, granite, or even certain metals, allowing industries to leverage them for detailed engravings on memorials, decorative pieces, and jewelry.

Boat Making: The marine industry, particularly smaller boat and kayak manufacturers, use CNC routers to cut precise and repeatable shapes from lightweight materials, ensuring both aesthetic appeal and functionality.

Which Features Do the Best CNC Routers Offer?

The best CNC routers in the market distinguish themselves by a combination of features that promote accuracy, efficiency, and user-friendliness.

Advanced Drive Systems: Premium CNC routers often feature helical rack and pinion drive systems or high-precision ball screws. These systems ensure that the router delivers maximum precision with every cut.

High-Speed Processing: In industries where production timelines are crucial, the processing speed of a CNC router can make all the difference. The best ones are equipped with high-speed spindles and advanced motors to facilitate rapid cutting without compromising on quality.

Automatic Tool Changers (ATC): This feature is particularly beneficial when different cuts or engravings require multiple tools. An ATC system automates the tool change process, ensuring efficiency and minimizing manual intervention.

T-slot Tables: A T-slot table allows for versatile and secure clamping of materials. It provides flexibility in setting up various projects and ensures the material remains stable during operations.

Advanced Dust Collection: As routers cut through materials, they produce dust and shavings, which can be hazardous and messy. An efficient dust collection system not only ensures a cleaner working environment but also prolongs the machine’s life by preventing dust buildup in critical components.

Some Other Considerations

When considering a CNC router purchase, beyond the machine’s features, several other considerations can affect your decision.

Training and Support: The learning curve associated with CNC routers can be steep. Opt for manufacturers or sellers that offer comprehensive training, whether through hands-on sessions, online tutorials, or detailed manuals.

Scalability and Upgrades: Your needs might evolve over time. A CNC router that allows for upgrades, be it in terms of software or hardware components, ensures you get the maximum value from your investment.

Warranty and Maintenance: A robust warranty can be a lifesaver. Also, consider how easy it is to get replacement parts or service. Some brands offer on-site servicing, which can be a significant advantage.

Software Compatibility: Ensure the CNC router is compatible with popular design software in your industry. It’s also a plus if it can handle various file formats.

Community and User Reviews: Before finalizing a purchase, spend time researching user reviews, and possibly join forums or groups dedicated to CNC routing. The experiences of others can offer invaluable insights and help you make an informed decision.