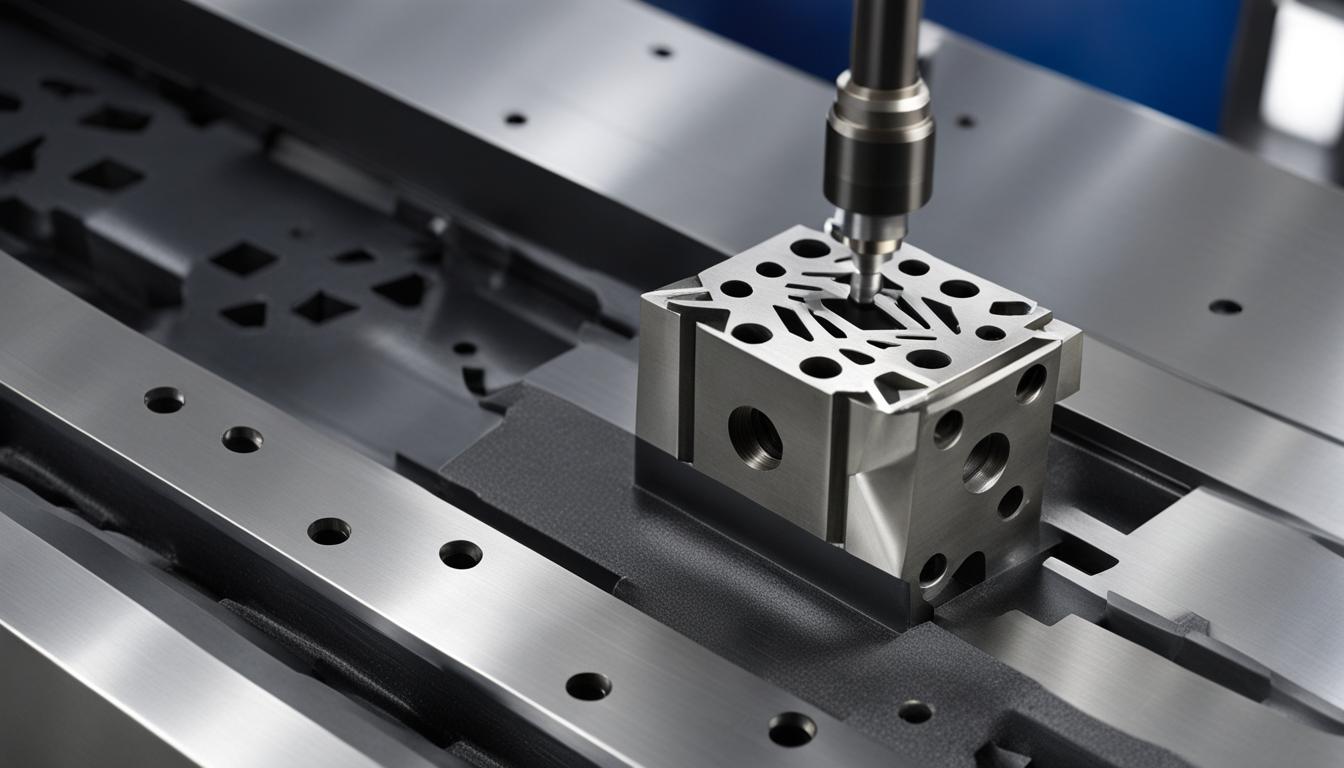

CNC metal milling is a precision manufacturing process that uses computer-controlled machines to remove material from a metal workpiece, creating complex shapes and components with high accuracy. The process begins with a 3D CAD model of the desired part, which is then converted into a set of instructions for the CNC machine using specialized software. These instructions, known as G-code, guide the machine’s cutting tools along precise paths to shape the metal.

The CNC milling machine typically features a rotating cutting tool, such as an end mill or face mill, which moves along multiple axes while the workpiece remains stationary. As the tool makes contact with the metal, it removes material in small increments, gradually forming the desired shape. The machine’s computer control ensures consistent speed, depth, and positioning throughout the milling process, resulting in highly accurate and repeatable parts.

CNC metal milling can handle a wide range of materials, including aluminum, steel, titanium, and brass, and is capable of producing both simple and intricate designs with tight tolerances. This versatile manufacturing method is widely used in industries such as aerospace, automotive, and medical device production, where precision and reliability are paramount.

- CNC metal milling is a powerful manufacturing process that utilizes Computer Numerical Control (CNC) machines.

- The process involves the removal of material from a workpiece using cutting tools, resulting in the production of finished parts.

- CNC milling machines are controlled by CAD software, which allows for precise design and conversion into machine-readable instructions.

- Various types of CNC milling machines are available, each with its own advantages and suitable applications.

- The benefits of CNC milling include high precision, repeatability, flexibility, reduced waste, shorter production time, and lower labor costs.

Understanding CNC Milling and its Process

The CNC milling process is a highly efficient and precise manufacturing method that involves the use of Computer-Aided Design (CAD) software, G-code instructions, cutting tools, and advanced automation. Let’s explore the intricacies of CNC milling and how it works.

Firstly, the process begins with the creation of a digital design using CAD software. This design serves as a blueprint for the part to be manufactured. The CAD software allows for precise modeling and customization of the part, ensuring accuracy and functionality.

Once the design is ready, it is converted into G-code, a language that the CNC machine understands. The G-code contains instructions that specify the tool’s path, the cutting speeds, and other parameters required for the milling process. This conversion process ensures seamless communication between the software and the CNC machine.

The CNC milling machine consists of a table, a spindle, and cutting tools. The table holds the workpiece in place, while the spindle rotates at high speeds, driving the cutting tools. The cutting tools move along the X, Y, and Z axes, precisely removing material from the workpiece according to the G-code instructions. This meticulous movement enables the creation of complex shapes, intricate details, and high-quality finishes.

One of the greatest advantages of CNC milling is its ability to achieve exceptional precision and repeatability. The automated nature of the process eliminates human errors and ensures consistent results, even when producing multiple identical parts. This level of precision is invaluable in industries such as aerospace, automotive, and medical, where accuracy is critical.

Key Elements of CNC Milling Process:

| CAD Software | G-code | Cutting Tools | Precision |

|---|---|---|---|

| Enables digital design creation | Instructions for CNC machine | Remove material from workpiece | Highly accurate manufacturing |

| Convert design into G-code | Defines tool path and speeds | Move along X, Y, and Z axes | Consistent results |

Types of CNC Milling Machines

The world of CNC milling machines offers a wide variety of options, each with its own set of advantages and applications. By understanding the different types of machines available, manufacturers can select the most suitable one for their specific needs.

Vertical Milling Machines

Vertical milling machines feature a vertically-oriented spindle that moves along the Z-axis. This design allows for easy positioning and precision cutting of vertical surfaces. Vertical milling machines are commonly used for tasks such as face milling, end milling, and drilling.

Horizontal Milling Machines

In contrast to vertical milling machines, horizontal milling machines have a horizontally-oriented spindle that moves along the X and Y axes. This configuration enables efficient removal of material from the sides of a workpiece. Horizontal milling machines are ideal for tasks such as slot milling, contour milling, and pocket milling.

Universal Milling Machines

Universal milling machines combine the capabilities of both vertical and horizontal milling machines. They feature a swivel head that can be positioned at various angles, allowing for both vertical and horizontal milling operations. This versatility makes universal milling machines suitable for a wide range of tasks.

Five-Axis Milling Machines

Five-axis milling machines offer enhanced precision and flexibility by adding two additional rotational axes to the X, Y, and Z axes. This allows for the creation of complex shapes and contours without the need for multiple setups. Five-axis milling machines are commonly used in industries such as aerospace and automotive.

Gantry Milling Machines

Gantry milling machines are heavy-duty machines that feature a bridge-like structure with a horizontal rail system. This design provides stability and rigidity, making gantry milling machines suitable for large-scale projects and heavy-duty machining tasks. They are commonly used in industries such as defense and manufacturing.

By understanding the differences between vertical milling machines, horizontal milling machines, universal milling machines, five-axis milling machines, and gantry milling machines, manufacturers can make informed decisions when selecting a CNC milling machine for their specific requirements.

Essential Operations and Techniques in CNC Milling

CNC milling involves several essential operations and techniques that contribute to the precision and quality of the final product. Understanding these operations is crucial for optimizing the milling process and achieving the desired outcomes.

1. Face Milling

Face milling is a vital operation in CNC milling that focuses on creating a smooth, flat finish on the surface of a workpiece. This technique is commonly used to remove material and achieve a precise surface finish. Face milling cutters are used, which have multiple cutting edges that remove material as they rotate.

2. Slot Milling

Slot milling is another important operation in CNC milling that involves cutting slots or grooves in a workpiece. This technique is often used to create keyways, channels, or other specific shapes in the material. Slot milling can be performed using end mills or specialized slotting cutters, depending on the desired slot size and shape.

3. Pocket Milling

Pocket milling is used to create hollow cavities or pockets in a workpiece. This technique is commonly employed when designing parts that require recesses or spaces for other components. Pocket milling involves removing material from the inside of the workpiece, leaving behind the desired pocket shape.

4. Contour Milling

Contour milling is the process of cutting along the contours of a workpiece to create specific shapes. This technique is often utilized when manufacturing parts with complex or intricate geometries. Contour milling requires precise control of the cutting tool’s path to accurately follow the desired contour.

5. Drilling and Boring

In addition to milling operations, CNC milling machines can also perform drilling and boring. Drilling involves creating holes in the workpiece, while boring is used to enlarge existing holes. These operations are essential for integrating fasteners, creating openings for cables, or accommodating other components in the final product.

| Operation | Description |

|---|---|

| Face Milling | Creates a smooth, flat finish on the workpiece surface. |

| Slot Milling | Cuts slots or grooves in the workpiece. |

| Pocket Milling | Creates hollow cavities or pockets in the workpiece. |

| Contour Milling | Cuts along the contours of the workpiece to create specific shapes. |

| Drilling | Creates holes in the workpiece. |

| Boring | Enlarges existing holes in the workpiece. |

Each of these operations requires careful planning, tool selection, and precise control of cutting parameters such as spindle speed, feed rate, and depth of cut. By mastering these essential operations and techniques, manufacturers can unlock the full potential of CNC milling and achieve superior results in their manufacturing processes.

https://www.youtube.com/watch?v=j6d5bvGTLQE

Advantages of CNC Milling in Manufacturing

CNC milling offers several advantages over traditional manufacturing methods. Its precision and repeatability make it ideal for producing high-quality parts with tight tolerances. The automated process ensures consistent results, reducing the risk of human error. This level of precision allows for the creation of complex and intricate designs that would be difficult to achieve manually.

One of the key advantages of CNC milling is its flexibility. CNC milling machines can handle a wide range of materials, including metals, plastics, and composites. They can also perform a variety of operations, such as drilling, milling, and contouring. This versatility makes CNC milling suitable for a wide range of industries and applications.

In addition to precision and flexibility, CNC milling also offers significant cost and time savings. By automating the manufacturing process, CNC milling reduces the need for manual labor, resulting in reduced labor costs. The automated process also eliminates the need for multiple setups and manual tool changes, leading to shorter production times.

Furthermore, CNC milling produces less waste compared to traditional methods. The computer-controlled cutting tools optimize material usage, minimizing scrap and reducing material costs. This not only helps to minimize environmental impact but also improves overall production efficiency.

| Advantages of CNC Milling in Manufacturing | |

|---|---|

| Precision | The computer-controlled nature of CNC milling ensures high precision and tight tolerances for consistent quality. |

| Repeatability | CNC milling machines can produce identical parts with high repeatability, ensuring consistency in manufacturing. |

| Flexibility | CNC milling machines can handle a wide range of materials and operations, offering versatility in manufacturing. |

| Reduced Waste | The computer-controlled cutting tools optimize material usage, minimizing waste and improving efficiency. |

| Shorter Production Time | The automated process of CNC milling eliminates manual labor and reduces setup and tool change time, resulting in shorter production times. |

| Reduced Labor Costs | Automation in CNC milling reduces the need for manual labor, resulting in lower labor costs for manufacturers. |

In conclusion, CNC milling brings numerous advantages to the manufacturing industry. Its precision, repeatability, flexibility, reduced waste, shorter production time, and reduced labor costs make it a preferred method for producing high-quality products efficiently.

Key Factors for Efficient CNC Milling

Efficient CNC milling relies on several key factors that contribute to optimal performance and high-quality results. These factors include material selection, cutting tool selection, spindle speed, feed rate, depth of cut, and coolant and lubrication.

Material Selection

The choice of material plays a crucial role in CNC milling. Different materials have varying properties and cutting characteristics that affect the machining process. Factors such as hardness, ductility, heat resistance, and chemical reactivity need to be considered when selecting the appropriate material for a specific application. By understanding the material’s properties, manufacturers can choose the most suitable material for their desired outcome.

Cutting Tool Selection

The selection of cutting tools is equally important in achieving efficient CNC milling. Different cutting tools are designed for specific materials and machining operations. Factors such as tool material, geometry, and coatings can significantly impact tool life, cutting speed, and surface finish. By carefully selecting cutting tools based on the material and operation, manufacturers can optimize the cutting process and achieve accurate and consistent results.

Spindle Speed, Feed Rate, and Depth of Cut

The spindle speed, feed rate, and depth of cut are critical parameters that affect the efficiency and quality of CNC milling. The spindle speed determines the rotational speed of the cutting tool, while the feed rate controls how quickly the tool advances along the workpiece. The depth of cut determines the thickness of material removed with each pass. Finding the optimal balance between these parameters is essential for efficient material removal, minimizing tool wear, and achieving desired surface finish.

Coolant and Lubrication

Proper coolant and lubrication are vital for successful CNC milling operations. Coolant helps dissipate heat generated during cutting, preventing overheating and prolonging tool life. Lubrication reduces friction between the tool and the workpiece, minimizing wear and ensuring smooth cutting. The choice and application of coolant and lubrication depend on factors such as material, cutting conditions, and environmental considerations. By employing suitable coolant and lubrication techniques, manufacturers can enhance tool performance and maintain quality throughout the milling process.

Tips for Optimizing CNC Milling Operations

Optimizing CNC milling operations is crucial for maximizing efficiency and achieving high-quality results. By implementing the following tips, manufacturers can enhance their milling processes and optimize performance.

Proper Workholding

Effective workholding is essential for stable and accurate milling operations. Choosing the right workholding solution ensures that the workpiece remains securely in place, minimizing vibrations and potential errors. Whether using vices, clamps, or fixtures, selecting the appropriate workholding method for each specific task is crucial.

Suitable Cutting Tools

Selecting the right cutting tools is a critical factor in CNC milling success. Consider the material being machined, the desired cutting speed and feed rate, and the specific application requirements. Utilizing appropriate tool geometries, coatings, and materials can improve performance, extend tool life, and achieve the desired surface finish.

Tool Maintenance

Maintaining cutting tools is essential for consistent performance and prolonging their lifespan. Regularly inspecting and replacing worn-out or damaged tools ensures optimal cutting conditions. Proper tool cleaning, lubrication, and calibration are necessary for sustaining accuracy and preventing premature wear.

Machine Calibration

Regular calibration of the CNC milling machine is crucial for maintaining accuracy and precision. Calibration includes checking and adjusting the machine’s axes, spindle alignment, and tool position. By ensuring that the machine is properly calibrated, manufacturers can achieve reliable and repeatable results.

Programming Optimization

Optimizing CNC programs and tool paths contributes to improved efficiency and productivity. By optimizing the cutting sequence, feed rates, and tool change points, manufacturers can minimize idle time and reduce the overall machining cycle. Utilizing advanced programming techniques, such as adaptive machining or intelligent toolpath generation, can further enhance performance.

| Tips for Optimizing CNC Milling Operations |

|---|

| Proper Workholding |

| Suitable Cutting Tools |

| Tool Maintenance |

| Machine Calibration |

| Programming Optimization |

Applications of CNC Milling across Industries

CNC milling has revolutionized various industries, offering precise and efficient manufacturing solutions. Let’s explore some of the key applications of CNC milling in different sectors:

Aerospace

The aerospace industry heavily relies on CNC milling for the production of complex and lightweight components. CNC machines are used to create intricate parts such as turbine blades, structural components, and aerospace-grade alloys. The high precision and repeatability of CNC milling ensure the reliability and safety of critical aerospace components.

Automotive

In the automotive industry, CNC milling plays a crucial role in manufacturing engine components, transmission parts, chassis components, and prototype development. CNC milling machines are capable of machining various materials like aluminum, steel, and composites, allowing the automotive sector to achieve superior quality, efficiency, and design flexibility.

Medical

CNC milling is widely used in the medical field for producing customized implants, prosthetics, surgical instruments, and dental components. The ability to work with biocompatible materials and create intricate designs makes CNC milling an ideal choice for manufacturing precise medical devices. It enables the production of patient-specific solutions, enhancing the effectiveness of medical treatments.

Electronics, Defense, and Telecommunications

In the electronics, defense, and telecommunications industries, CNC milling is crucial for the production of circuit boards, connectors, enclosures, and specialized components. CNC machines offer high precision, enabling the creation of intricate electronic components with tight tolerances. The defense and telecommunications sectors benefit from CNC milling’s ability to produce complex parts that meet strict performance requirements.

| Industry | Applications |

|---|---|

| Aerospace | Turbine blades, structural components, aerospace-grade alloys |

| Automotive | Engine components, transmission parts, chassis components, prototype development |

| Medical | Implants, prosthetics, surgical instruments, dental components |

| Electronics, Defense, and Telecommunications | Circuit boards, connectors, enclosures, specialized components |

These are just a few examples of how CNC milling is applied across industries. Its versatility, precision, and efficiency make it an indispensable technology for manufacturing critical components in a wide range of sectors.

The Future of CNC Milling

In recent years, technological advancements have propelled CNC milling to new heights, and the future looks even more promising. Several key trends and innovations are shaping the future of CNC milling, including AI integration, additive manufacturing, hybrid manufacturing, IoT integration, and predictive maintenance.

AI integration is revolutionizing CNC milling by optimizing machine performance and enabling predictive analytics. By leveraging AI algorithms, machines can adapt and optimize their operations based on real-time data, resulting in increased efficiency and reduced downtime. AI-driven CNC milling systems can anticipate errors and make adjustments on the fly, ensuring high-quality and accurate machining.

Another exciting development is the integration of additive manufacturing with CNC milling. Additive manufacturing, also known as 3D printing, allows for the creation of intricate internal structures and complex geometries that were previously impossible with traditional milling processes. By combining additive manufacturing and CNC milling, manufacturers can achieve precise external finishes and produce highly customized parts.

The Future of CNC Milling Trends

| Trend | Description |

|---|---|

| AI Integration | Optimizes machine performance and enables predictive maintenance. |

| Additive Manufacturing | Combines 3D printing with CNC milling for intricate internal structures and precise external finishes. |

| Hybrid Manufacturing | Integration of multiple manufacturing processes to leverage their respective advantages. |

| IoT Integration | Enables real-time monitoring and data-driven decision-making. |

| Predictive Maintenance | Uses data analytics to anticipate and prevent machine failures. |

Hybrid manufacturing is also gaining traction, combining different manufacturing processes to leverage their respective strengths. By integrating CNC milling with other techniques like 3D printing or laser cutting, manufacturers can capitalize on the benefits of each process and produce complex parts more efficiently.

Furthermore, the integration of CNC milling with the Internet of Things (IoT) brings real-time monitoring and data-driven decision-making to the manufacturing floor. IoT-enabled CNC machines can collect and analyze data, offering valuable insights for process optimization and quality control.

Predictive maintenance is another key trend in CNC milling. By leveraging data analytics and machine learning algorithms, manufacturers can predict and prevent machine failures before they occur. This proactive approach reduces downtime, increases productivity, and extends machine lifespan.

Conclusion: Harnessing the Power of CNC Milling

CNC metal milling is an indispensable manufacturing process that offers numerous advantages to industries across the board. By fully understanding the intricacies of the CNC milling process and implementing efficient techniques, manufacturers can harness its power to create high-quality products with precision and consistency.

One of the key benefits of CNC milling is its ability to enhance manufacturing efficiency. With computer-controlled automation and precise cutting tools, CNC milling machines can produce parts with exceptional accuracy and repeatability. This not only ensures consistent quality but also reduces waste and shortens production time, leading to improved overall efficiency.

Moreover, CNC milling enables the creation of high-quality products. The precision and control provided by the automated process result in parts with tight tolerances and smooth finishes. This ensures that the final products meet the required specifications and can withstand rigorous use in various industries and applications.

In conclusion, CNC milling is a fundamental technology driving manufacturing efficiency and the production of high-quality products. By harnessing the power of CNC milling, industries can achieve enhanced precision, repeatability, and flexibility, ultimately leading to improved profitability and customer satisfaction.