The five leading CNC software solutions, each with distinct features and capabilities, are Fusion 360, Mastercam, SolidWorks CAM, CATIA, and Siemens NX. Fusion 360 stands out for its cloud-based platform, offering integrated CAD/CAM functionality and collaborative tools. Mastercam excels in multi-axis machining and provides a wide range of toolpath strategies. SolidWorks CAM integrates seamlessly with SolidWorks CAD, offering a unified environment for design and manufacturing.

CATIA, known for its use in aerospace and automotive industries, provides advanced surface modeling and simulation capabilities. Siemens NX offers a comprehensive suite of CAD/CAM/CAE tools, with powerful machining algorithms and automation features. These software giants cater to various industry needs, from small-scale prototyping to large-scale industrial production, offering different levels of complexity, pricing models, and specialized features.

Users should consider factors such as ease of use, compatibility with existing systems, available post-processors, and industry-specific requirements when choosing the most suitable CNC software for their operations.

- Exploring the features and capabilities of the top CNC software options available in the market.

- Evaluating key factors such as features, pricing, and performance when comparing CNC software providers.

- Reviewing BIESSE Rover A, Stiles/HOMAG P-210/110, Casadei Busellato Jet Master T/RT, SCM accord, and HOLZ-HER Nextec.

- Considering the strengths and weaknesses of each provider to determine which CNC software suits your specific needs.

- Making an informed decision based on our comprehensive and unbiased reviews.

Introduction to CNC Software

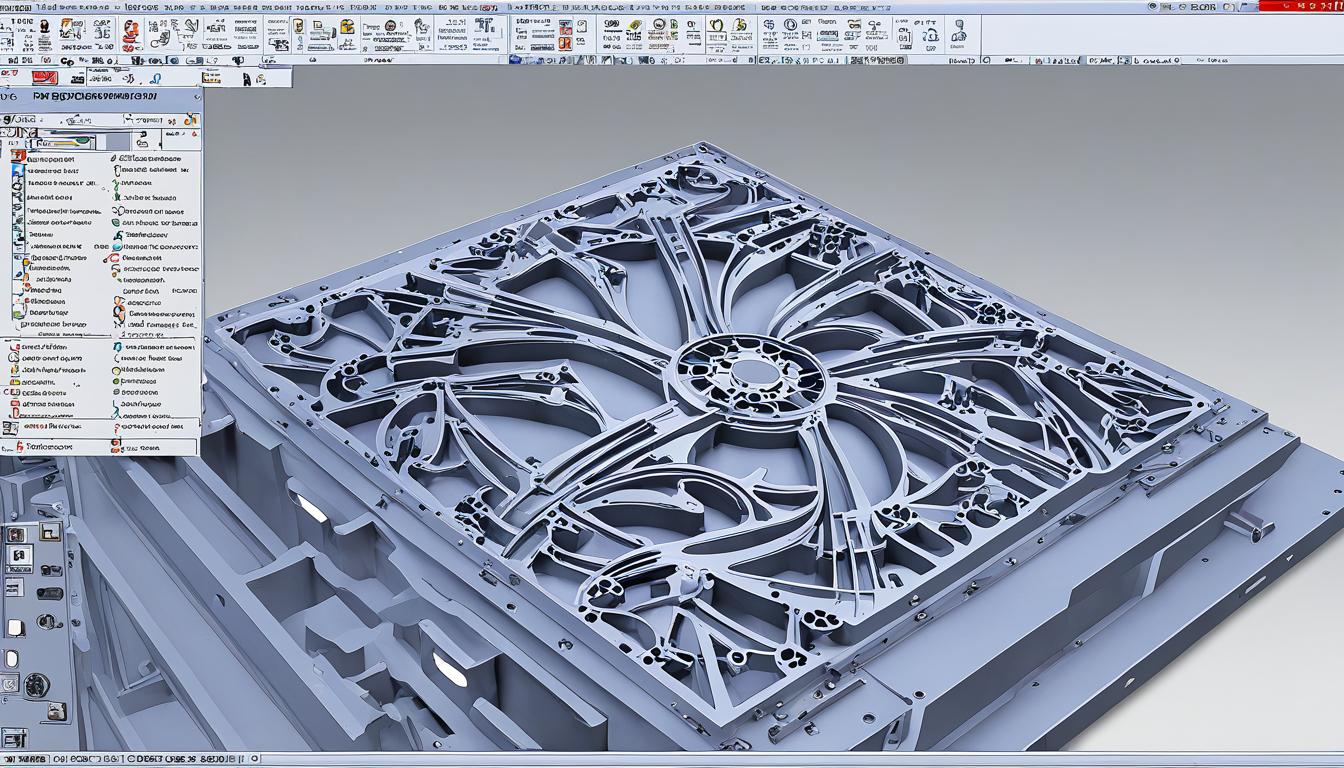

When it comes to controlling CNC machines, the right software is essential for precision and efficiency. CNC software comprises CAD (Computer-Aided Design) software for part design and CAM (Computer-Aided Manufacturing) software for generating toolpaths and G-code instructions. In this section, we will delve into the top-rated CNC software options available in the market and analyze their features and capabilities.

CNC software plays a critical role in streamlining the machining process, allowing manufacturers to create intricate designs and execute complex operations with ease. By combining the power of CAD and CAM, CNC software provides a comprehensive solution for designing and manufacturing parts.

Whether you are a small workshop or a large-scale production facility, choosing the right CNC software can significantly impact your efficiency, productivity, and overall success. To help you make an informed decision, we have analyzed and compared the top-rated CNC software providers in terms of their features, user-friendliness, performance, and value for money.

Throughout the following sections, we will explore the key factors to consider when comparing CNC software, such as features, pricing, and performance. Additionally, we will provide in-depth reviews of each of the five leading CNC software options, including BIESSE Rover A, Stiles/HOMAG P-210/110, Casadei Busellato Jet Master T/RT, SCM accord, and HOLZ-HER Nextec.

Stay tuned as we dive into the world of CNC software and uncover the strengths and weaknesses of these top-rated solutions. Whether you’re a seasoned professional or new to CNC machining, this analysis will help guide you towards choosing the best CNC software for your specific needs.

Key Factors to Consider

When comparing CNC software, it is essential to take into account several key factors that can greatly impact your decision-making process. These factors include the software’s features and capabilities, pricing and licensing options, as well as its performance and speed.

Features and Capabilities

The first aspect to evaluate when comparing CNC software is the range of features and capabilities it offers. Look for software that provides efficient CAD (Computer-Aided Design) tools for designing your parts and robust CAM (Computer-Aided Manufacturing) functionality for generating accurate toolpaths and G-code instructions.

Consider whether the software supports advanced machining techniques such as 3D carving, nesting, and the ability to work with different materials. These features can enhance your productivity and enable you to create complex and intricate designs with ease.

Pricing and Licensing Options

Another crucial factor to consider is the pricing and licensing options of the CNC software. Determine if the software offers flexible pricing models, such as one-time purchases, subscription plans, or tiered pricing based on the features you need.

Take note of any additional charges for specific features or modules, as these can significantly impact the overall cost of the software. It’s important to find a pricing structure that aligns with your budget and business needs.

Performance and Speed

The performance and speed of the CNC software are critical for maximizing productivity and efficiency in your machining operations. Consider how fast the software can generate toolpaths, execute machining operations, and handle large or complex designs.

Look for software that provides smooth and seamless integration with CNC machines, allowing for real-time monitoring and control. A quick and responsive software can significantly reduce production time and minimize errors.

BIESSE Rover A

BIESSE Rover A is a highly regarded CNC software option that offers a wide range of features and capabilities. It is known for its ability to work with different materials and provide nesting functionality. With BIESSE Rover A, users can expect efficient machining operations and precise results.

This CNC software supports various cutting and milling operations, making it a versatile solution for different manufacturing needs. It allows users to work with a variety of materials, including wood, plastic, and composite materials. BIESSE Rover A is designed to optimize productivity and deliver high-quality outputs.

Some notable features of BIESSE Rover A include:

- Advanced nesting capabilities: The software offers nesting functionalities that can maximize material utilization and minimize waste.

- Compatibility with different machine types: BIESSE Rover A is compatible with a wide range of CNC machines, providing flexibility for users.

- User-friendly interface: The software is designed to be intuitive and user-friendly, allowing users to easily navigate and operate the CNC machine.

However, it’s important to note that some users have reported additional charges for certain features of BIESSE Rover A. These additional charges can increase the overall cost of the software, and users should consider this when making a decision.

Customer Reviews

Here are some comments from customers who have used BIESSE Rover A:

“BIESSE Rover A has significantly improved our production processes. The nesting functionality has allowed us to reduce material waste and increase efficiency.”

“The compatibility with different machine types makes BIESSE Rover A a versatile solution for our manufacturing needs. We have been able to achieve consistent and precise results.”

These customer reviews highlight the positive impact of BIESSE Rover A on manufacturing operations and the overall satisfaction of users.

Stiles/HOMAG P-210/110

Stiles/HOMAG P-210/110 is a leading CNC software provider known for its exceptional capabilities in the industry. With a focus on meeting the diverse needs of manufacturers, they offer a range of options for both flat table and pod and rail configurations, providing flexibility in the machining process.

What sets Stiles/HOMAG P-210/110 apart is its hybrid capabilities, catering to both carving and flat stock cutting requirements. This enables users to create intricate designs with ease while also efficiently handling standard flat stock cutting tasks. The versatility of the software allows manufacturers to streamline their production processes and enhance overall productivity.

One of the notable features of Stiles/HOMAG P-210/110 is its support for 3D carved pieces. This feature opens up a world of possibilities for creating stunning and complex designs that truly stand out. Whether it’s decorative woodwork, intricate patterns, or custom furniture pieces, this software empowers manufacturers to achieve extraordinary results.

Furthermore, Stiles/HOMAG P-210/110 is backed by a comprehensive support system, ensuring that users receive the assistance they need whenever they need it. This commitment to customer satisfaction sets them apart from competitors, providing peace of mind and a seamless experience for users.

To give you a visual representation, here is a table highlighting the key features and benefits of Stiles/HOMAG P-210/110:

| Features | Benefits |

|---|---|

| Hybrid capabilities | Efficiently handle carving and flat stock cutting tasks |

| Support for 3D carved pieces | Create intricate and visually stunning designs |

| Flexible configuration options | Adapt to different machining requirements |

| Comprehensive customer support | Assistance whenever it’s needed |

With Stiles/HOMAG P-210/110, manufacturers can unlock their full potential and achieve exceptional results in their CNC machining processes. The combination of advanced features, flexibility, and outstanding customer support makes it a top choice for businesses looking to enhance their productivity and create exceptional 3D carved pieces.

Casadei Busellato Jet Master T/RT

Casadei Busellato Jet Master T/RT is a reliable CNC software option that offers cutting and edge polishing capabilities for thick acrylic materials. With its advanced features and precision, it is a popular choice among manufacturers working with acrylic.

One of the key advantages of Casadei Busellato Jet Master T/RT is its ability to handle thick acrylic materials with ease. Whether you need to cut intricate designs or polish the edges for a smooth finish, this software provides the necessary tools and functionalities.

With a range of fixturing options and vacuum modules, Casadei Busellato Jet Master T/RT ensures precision and stability during the machining process. This results in accurate cuts and polished edges that meet the highest quality standards.

When it comes to pricing, Casadei Busellato Jet Master T/RT is on par with other top providers in the market. While the software might require an investment, its capabilities and performance make it a valuable addition to any CNC machine setup.

Overall, Casadei Busellato Jet Master T/RT is a reliable and efficient CNC software option for cutting and edge polishing thick acrylic materials. Its advanced features, precision, and competitive pricing make it a compelling choice for manufacturers looking to optimize their acrylic machining processes.

SCM Accord

SCM Accord is a reputable CNC software provider known for its exceptional 5-axis CNC routing capabilities. With the ability to work with a variety of materials, including solid woods and thick woods, SCM Accord offers versatility and precision in machining operations. Its advanced features and intuitive interface make it a popular choice among professionals in the industry.

The 5-axis CNC router technology provided by SCM Accord allows for complex and intricate designs, enabling users to achieve exceptional levels of detail and accuracy. The flexibility of the 5-axis CNC router opens up a world of possibilities, making it ideal for industries that require intricate and precise machining, such as aerospace, automotive, and woodworking.

It’s important to note that implementing SCM Accord’s software may require additional training and expertise due to the intricacies of 5-axis CNC routing. However, the investment in training can yield great returns in terms of enhanced productivity and expanded capabilities.

If you’re looking for a CNC software solution that excels in 5-axis CNC routing and offers exceptional precision and accuracy, SCM Accord is definitely worth considering.

Key Features of SCM Accord:

- 5-axis CNC routing capabilities

- Ability to work with a variety of materials

- Advanced features for complex designs

- Intuitive interface

- Precision and accuracy in machining operations

| Provider | 5-Axis CNC Router Capabilities | Material Compatibility | Advanced Features |

|---|---|---|---|

| SCM Accord | ✓ | Wide range of materials, including solid woods and thick woods | ✓ |

| BIESSE Rover A | ✗ | Limited material compatibility | ✓ |

| Stiles/HOMAG P-210/110 | ✗ | Wide range of materials | ✓ |

| Casadei Busellato Jet Master T/RT | ✗ | Limited material compatibility | ✗ |

| HOLZ-HER Nextec | ✗ | Wide range of materials | ✓ |

HOLZ-HER Nextec

HOLZ-HER Nextec is a renowned CNC software option that specializes in design capabilities. With HOLZ-HER Nextec, users can unleash their creativity and bring intricate pieces to life by leveraging its advanced features. This powerful CNC software enables users to design complex shapes, visualize them in 3D, and assign precise cutting tasks to the CNC machine.

One of the main advantages of HOLZ-HER Nextec is its ability to optimize the cutting process, saving time and reducing material waste. Through its intuitive interface, users can easily fine-tune parameters such as feed rates and depth of cut, allowing for optimal performance and unparalleled precision.

While HOLZ-HER Nextec may come with a higher price tag compared to other CNC software options available in the market, its advanced functionalities make it a valuable investment. Whether you’re a professional woodworker or a hobbyist, HOLZ-HER Nextec empowers you to take your designs to the next level and achieve exceptional results.