Injection molding and mold making have revolutionized the manufacturing industry, allowing for the mass production of intricate components in a variety of sectors, from automotive to medical. However, with the popularity and widespread adoption of these techniques, a few myths have cropped up. Let’s tackle two of the most common misconceptions head-on.

Myth 1: Any Shape is Moldable

The Misconception:

Many believe that whatever shape you can dream up, it can be made into reality using injection molding.

The Truth:

While injection molding is incredibly versatile and capable of producing highly complex shapes, there are certain design constraints to consider.

- Undercuts: These are protrusions or recesses in a design that can prevent a straightforward ejection from the mold. Designs with undercuts typically require specialized mold designs, like side-actions or collapsible cores, which can increase mold complexity and cost.

- Draft Angles: These are slight tapers on the side walls of the part. Without proper draft angles, the part can get stuck inside the mold. The more intricate the design, the more attention must be paid to ensuring these angles are correct.

- Wall Thickness: Even wall thickness is crucial for the part to cool and solidify uniformly. Variations in wall thickness can lead to defects like sink marks or warping.

Myth 2: Plastic Injection Molding is Not Ideal for Prototyping

The Misconception:

Many think that injection molding is only for mass production and not suitable for creating prototypes.

The Truth:

While it’s true that traditional injection molding can be costly and time-consuming for just a few prototype parts, rapid injection molding has emerged as an excellent option for prototyping.

- Rapid Tooling: This method uses molds made from softer, less durable materials which are quicker and cheaper to produce. While they won’t last for hundreds of thousands of cycles like hardened steel molds, they are ideal for small runs.

- Short Lead Times: Thanks to advancements in technology and techniques, it’s now possible to get parts in days, not weeks. This speed is vital for companies that need to iterate designs quickly.

- Material Selection: Prototyping often requires the final material that will be used in the product for accurate testing. Injection molding offers a wide variety of materials, making it a good choice for prototyping.

- Cost-effective for Small Batches: Contrary to popular belief, when taking advantage of rapid tooling and other advancements, injection molding can be cost-effective even for smaller batches.

Myth 3: The Production Cycle of Molds is Short

The Misconception:

Many assume that once a design is finalized, the mold production cycle is just a quick step before mass production can commence.

The Truth:

The production cycle for molds, particularly complex ones, can be quite extensive. While the actual injection molding process may only take seconds to minutes, the steps leading up to it are intricate and time-consuming.

- Design Phase: Before a mold can be manufactured, it needs to be carefully designed, keeping in mind factors like material flow, cooling, and ejection. This design phase can be lengthy, especially if revisions are needed.

- Material Selection for the Mold: Depending on the part’s requirements and the production volume, the mold material (aluminum, pre-hardened steel, hardened steel, etc.) must be chosen. Each material has its own processing time and complexities.

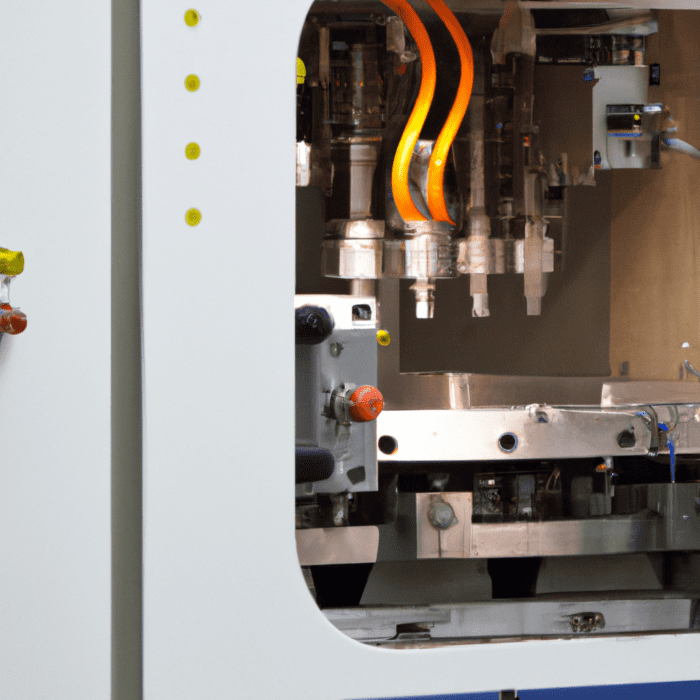

- Machining and Fine-tuning: Once designed, molds need to be machined, which can be a time-consuming process, especially for high-precision parts. After machining, the mold often requires fine-tuning and adjustments.

- Testing: Before full-scale production, the mold undergoes several tests to ensure it produces accurate and defect-free parts. This can involve multiple iterations.

Myth 4: Mold Making Produces a Lot of Scrap

The Misconception:

The perception is that mold making, especially the machining process, generates vast amounts of waste material.

The Truth:

While some material waste is inevitable during the mold making process, several measures are in place to minimize scrap and make the process as efficient as possible.

- Advanced Software: Modern Computer-Aided Manufacturing (CAM) software helps optimize machining paths to reduce waste and improve efficiency.

- High-Precision Machines: Modern machining centers offer high precision, reducing errors and, therefore, wastage.

- Recycling: The metal scrap that is generated can often be recycled. Many mold-making facilities have processes in place to collect and recycle these materials, ensuring they are not truly wasted.

- Alternative Techniques: Methods like Electrical Discharge Machining (EDM) have been employed to shape molds in certain scenarios, which can produce less scrap than conventional machining.

Myth 5: Mold Making Produces an Excessive Amount of Scrap

The Misconception:

Many believe that the mold-making process inherently creates an excessive amount of waste material, making it less sustainable and efficient.

The Truth:

While there’s some material removal involved in mold making, advancements in technology and techniques have significantly reduced waste.

- Subtractive vs. Additive Manufacturing: Traditional mold making is a subtractive process, meaning material is removed to create the mold. While this can generate scrap, it’s essential to distinguish between “waste” and “recyclable scrap.” Most metal scraps from the mold-making process are recyclable, and many facilities ensure this material finds its way back into the production cycle.

- Efficiency Improvements: Modern mold-making techniques aim to use material more efficiently. For instance, nesting parts in CNC machining or using modular mold bases can minimize scrap.

Myth 6: Only Injection Molding Parameters Can Solve Quality Problems

The Misconception:

When defects or quality issues arise in the molded parts, many jump to the conclusion that tweaking the injection molding machine’s parameters is the sole solution.

The Truth:

While injection molding parameters (like temperature, pressure, and cycle time) play a crucial role in the quality of the final part, they aren’t the only factors at play.

- Mold Design: A well-designed mold is fundamental. Issues like poor venting, inappropriate gate location, or inadequate cooling channels can lead to defects in the final parts. Sometimes, the mold itself may need a design modification to address quality issues.

- Material Selection: Using the wrong type of plastic or not drying it adequately before molding can result in defects. Ensuring the right material is chosen and properly prepared is as crucial as fine-tuning the molding parameters.

- Post-Processing: Sometimes, quality issues can be addressed or minimized in post-processing stages, like trimming, painting, or assembly.

- Maintenance: Regular maintenance of the mold and the injection molding machine is essential. Wear and tear or minor damages to the mold can lead to quality issues in the molded parts.

- Training: Ensuring that machine operators and technicians are well-trained and understand both the machinery and the materials they are working with is vital. They need to recognize when a problem is due to machine parameters versus other external factors.