Turning and milling are two common machining processes used in the manufacturing industry. Turning is a machining process used to create rotational parts by cutting away unwanted material. It is typically used to create cylindrical parts, though it can also be used to create non-cylindrical shapes. The process is performed on a lathe, which holds the material in place while a cutting tool is used to remove material from the workpiece. The cutting tool is usually a single-point cutting tool, though other tools such as multi-point tools can also be used.

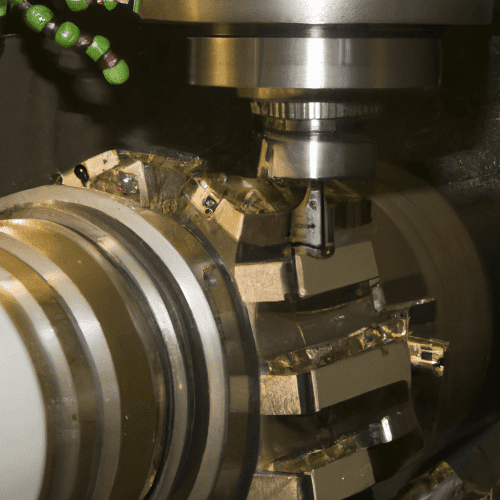

Milling is a machining process used to create flat and complex shapes with a rotating cutting tool. The cutting tool is usually a multi-point tool, such as an end mill, which rotates and moves along multiple axes to create the desired shape. The workpiece is held in place on a milling machine, which moves the cutting tool around the workpiece to create the desired shape. Milling can be used to create a variety of shapes, including flat surfaces, slots, pockets, and even 3D shapes.

What is meant by turning process?

The turning process is a machining operation in which a cutting tool is used to remove material from a workpiece to create a desired shape or finish. It is one of the most common and versatile machining processes, and is used to create a variety of shapes and sizes in a wide range of materials. The turning process is typically used to produce cylindrical parts, but can also be used to create other shapes such as squares, hexagons, and polygons. The cutting tool is typically a single-point cutting tool, but can also be a multi-point cutting tool. The cutting tool is held in a tool holder and is rotated at a predetermined speed while the workpiece is fed into the cutting tool. The cutting tool removes material from the workpiece in the form of chips, which are then removed from the workpiece. The turning process can be used to create a variety of features such as grooves, threads, and tapers. The turning process can also be used to create a variety of finishes such as smooth, rough, and textured.

Why is milling better than turning?

Milling is a machining process that uses a rotating multi-point cutting tool to remove material from a workpiece. It is generally considered to be more versatile than turning, as it is capable of cutting a wider variety of materials and shapes. Milling is also capable of producing more complex shapes than turning, as the cutting tool can move in multiple directions. Additionally, milling can be used to create a variety of features, such as slots, pockets, and grooves, which are not possible with turning.

Milling is also more efficient than turning, as it can produce a greater number of parts in a shorter amount of time. This is due to the fact that the cutting tool can move in multiple directions, allowing it to cut more material in a single pass. Additionally, milling can be used to produce parts with a greater degree of accuracy than turning, as the cutting tool can be precisely positioned and moved in a controlled manner.

What is turning milling and drilling?

Turning, milling, and drilling are all machining processes used in the manufacturing industry to shape and finish components. Turning is a machining process used to create cylindrical parts by rotating a workpiece while a cutting tool is fed into it. The cutting tool is usually a single-point cutting tool, but can also be a multi-point cutting tool. Milling is a machining process used to create flat and complex shapes by feeding a workpiece past a rotating cutting tool. The cutting tool is usually a multi-point cutting tool, but can also be a single-point cutting tool. Drilling is a machining process used to create holes in a workpiece by feeding a rotating cutting tool into the workpiece. The cutting tool is usually a twist drill, but can also be a reamer, counterbore, or countersink. All three processes are used to shape and finish components in the manufacturing industry.

What is the difference between CNC milling and turning?

CNC (Computer Numerical Control) milling and turning are two different machining processes used in the manufacturing industry. CNC milling is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a workpiece to create a custom-shaped part. CNC turning is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a cylindrical workpiece to create a custom-shaped part.

The main difference between CNC milling and turning is the type of cutting tool used. CNC milling uses a rotating cutting tool to remove material from the workpiece, while CNC turning uses a stationary cutting tool to remove material from the workpiece. CNC milling is typically used to create complex shapes and contours, while CNC turning is used to create cylindrical parts with a uniform diameter.

CNC milling is a more complex process than CNC turning, as it requires the use of multiple cutting tools and requires more precise programming.

What is the process of milling?

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. It is commonly used to create parts with complex shapes and features, such as slots, grooves, and contours. The process of milling begins with the selection of the appropriate cutting tool for the job. This tool is typically a multi-point cutting tool, such as an end mill or a drill bit. The cutting tool is then mounted in a milling machine, which is a machine that holds and rotates the cutting tool.

Once the cutting tool is mounted, the workpiece is then placed in the milling machine and secured in place. The cutting tool is then moved in a specific direction and at a specific speed to begin the cutting process. The cutting tool is typically moved in a linear direction, but can also be moved in a circular pattern. As the cutting tool moves, it removes material from the workpiece in the form of chips. The chips are then collected and disposed of.

What is metal turning process?

Metal turning is a machining process used to create components with cylindrical shapes. It is a type of subtractive manufacturing, which involves removing material from a workpiece to create the desired shape. The process is performed on a lathe, which is a machine tool that rotates the workpiece while a cutting tool is used to remove material from the workpiece. The cutting tool is typically a single-point cutting tool, which is a tool with a sharp cutting edge that is used to remove material from the workpiece.

The metal turning process begins with the selection of the appropriate cutting tool for the job. The cutting tool is then mounted in the lathe and the workpiece is mounted in the lathe as well. The cutting tool is then moved along the workpiece in a linear motion, while the workpiece is rotated. As the cutting tool moves along the workpiece, material is removed from the workpiece in order to create the desired shape. The cutting tool is moved in a linear motion along the workpiece in order to create the desired shape.

What is turning on a lathe?

Turning on a lathe is a machining process used to shape a variety of materials, such as metal, wood, and plastic. It is a subtractive manufacturing process, meaning that material is removed from the workpiece in order to create the desired shape. The process is performed on a lathe, which is a machine tool that rotates the workpiece while a cutting tool is moved against it to remove material.

The cutting tool is typically a single-point cutting tool, which is a tool with a sharp cutting edge that is held in a tool holder and moved against the workpiece. The cutting tool is usually fed into the workpiece in a linear direction, although some lathes are capable of performing more complex movements. The cutting tool is usually fed into the workpiece at a predetermined rate, which is determined by the speed of the lathe and the type of material being machined.

The cutting tool is usually made of high-speed steel or carbide, and is designed to cut the material at a specific rate.

What are the three main movements of turning operations?

Turning operations are a type of machining process used to shape and finish a workpiece by removing material from the surface. The three main movements of turning operations are the cutting tool’s feed, the cutting tool’s rotation, and the workpiece’s rotation.

The feed movement is the linear motion of the cutting tool along the workpiece’s surface. This motion is usually controlled by a feed rate, which is the distance the cutting tool moves in a given amount of time. The feed rate is typically measured in inches per minute (IPM). The feed rate is important because it determines the amount of material that is removed from the workpiece.

The cutting tool’s rotation is the rotational motion of the cutting tool around its own axis. This motion is usually controlled by a spindle speed, which is the rotational speed of the cutting tool. The spindle speed is typically measured in revolutions per minute (RPM). The spindle speed is important because it determines the cutting speed and the surface finish of the workpiece.

What is turning operation in the lathe machine?

Turning operation in a lathe machine is a machining process used to shape a workpiece by rotating it against a cutting tool. The cutting tool is typically a single-point cutting tool, such as a lathe tool bit, but can also be a multi-point tool, such as a form tool. The cutting tool is held in a tool holder and is fed into the rotating workpiece to remove material and create the desired shape. The cutting tool is usually fed along the axis of the workpiece, but can also be fed at an angle to create tapers and contours. The cutting tool can be moved in a variety of ways, including manual, semi-automatic, and fully automatic. The cutting speed, feed rate, and depth of cut are all adjustable to achieve the desired results. Turning operations can be used to create a variety of shapes, including round, square, hexagonal, and octagonal shapes. Turning operations can also be used to create threads, grooves, and other features.