Before you invest in a mini lathe, it’s important to make sure you know what you’re getting. Below are some things to consider before you buy a mini lathe.

- What type of material are you planning on machining? Different mini-lathes can accept different materials and sizes, so it’s important to choose a machine that fits the material you plan to be working with.

- What size does the mini lathe need to be? Standard mini-lathes range from 8” to 12” in diameter. Depending on the type of projects you’re looking to work on, a bigger size may be beneficial if you plan on turning larger-diameter pieces.

- How powerful should the motor be? Look for a motor with a power rating (in watts) that can adequately handle the job you have in mind. The higher the power rating, the sturdier the structure of the machine will be, as well as its ability to handle larger diameter materials and deeper cuts.

- What kind of offhand accessories should you consider? Offhand accessories such as tool rests, lathe chucks, faceplates, and center drills will extend the capabilities of your lathe and help produce more accurate cuts.

- How much do you want to spend? Set a budget for your lathe before you start your search. You can find good mini-lathes for less than $500, but higher-end models could be several thousand dollars.

- What should you look for in terms of warranties and shipping? Many manufacturers offer warranties, which can be helpful if you ever encounter an issue with your lathe. Additionally, look for a manufacturer that offers free shipping or a return policy in case the machine isn’t what you expected.

Ultimately, the mini lathe you choose should suit the type of material and projects you plan to work on. With the right selection, you can find a machine that fits your needs and budget and can help you take your projects to the next level.

What is a mini-lathe?

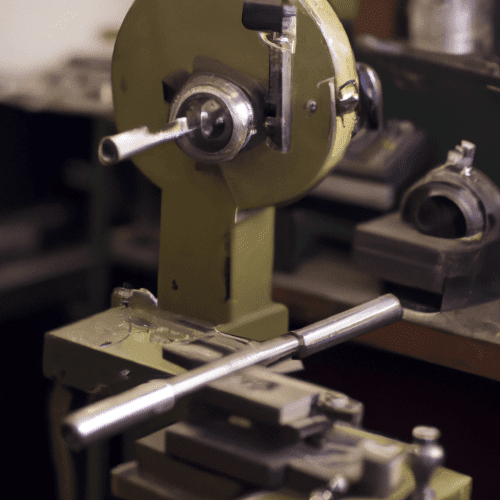

A mini-lathe is a power tool used in woodworking and metalworking. It is a smaller version of a traditional wood lathe, with a much shorter bed than the traditional model and typically has a smaller diameter. The mini-lathe is powered by a motor, often an electric one and it is used to turn small pieces of material, such as small pieces of wood, into a cylindrical shape.

A mini-lathe usually has a number of functions and features allowing it to cut, turn, face, taper, drill and sand material. It can also be used for thread cutting in order to create cylindrical parts with threads, such as screws and bolts. Mini-lathes are often used for hobbyists as well as for small production runs since they are relatively more affordable than traditional lathes, and require less space and maintenance.

What is the difference between a mini-lathe and a full-sized lathe?

The primary difference between a mini-lathe and a full-sized lathe is size. Mini-lathes are generally smaller and are made for smaller and more delicate projects, whereas full-sized lathes are larger and can handle bigger, more rugged jobs.

Mini-lathes are typically not capable of taking on large-scale projects and commonly have a shorter bed than full-sized lathes. This smaller bed size can limit the pieces you can turn with a mini-lathe and often it is not suitable for working on larger pieces of material. In addition, mini-lathes often have a maximum size of the material they can safely handle, typically ranging between five and seven inches in diameter.

Full-sized lathes are better suited for larger projects, as they are typically more heavy-duty and often capable of handling larger pieces of material. A full-sized lathe generally has a longer bed, which allows the use of longer pieces of material and provides increased stability when turning round objects. Full-sized lathes are also generally more powerful, providing more torque and having more speed options than mini-lathes.

When deciding between a mini-lathe and a full-sized lathe, it is important to consider the project at hand and the size of the material to be worked on. If the project requires smaller and more delicate work, then a mini-lathe might be the better option. However, if the project requires larger and more rugged work, then a full-sized lathe might be the more ideal choice.

What are benefits of mini-lathe’s?

The mini lathe is a great tool for both hobbyists and commercial users. It can be used to create a wide range of projects, including turning bowls, making wooden toys, and even doing custom gunsmithing. For hobbyists, the mini lathe can be an economical entry into the world of metal and woodworking. Here are some of its benefits.

- Compact size: Mini lathes are much smaller than traditional larger lathes, making them easier to use and store. This is especially helpful for hobbyists with limited space.

- Low cost: Mini lathes are usually much less expensive than traditional larger lathes, making them a great option for hobbyists who don’t want to invest too much money in a tool.

- Versatility: Mini lathes are very adaptable tools, able to turn wood and metals for several different projects. This makes them much more versatile than other tools.

- Precision: Mini lathes come with adjustable blades that can make very precise cuts for detailed projects. This makes them ideal for hobbies such as woodturning and gunsmithing.

- Safe: Most mini lathes come with safety guards and other features that make them safe and easier to use.

In conclusion, mini lathes are an excellent choice for hobbyists looking to get into wood and metalworking. Their size, cost and versatility make them a great choice for most projects.

Features to look for when looking for a mini-lathe

- Motor Power: Look for a mini-lathe with a motor that produces 1/3 to 1/2 horsepower and runs on 110- or 220-volt electricity. Make sure the motor is completely sealed, so that it won’t be subject to damage from dust and grime.

- Swing Over Bed: Look for a mini-lathe with a swing over bed of 12 inches or more, so it can accommodate larger work pieces.

- Spindle Speeds: Look for a mini-lathe with multiple spindle speeds (at least three is ideal), so you can work on different materials and create different sizes of projects.

- Chuck Thread: Check that the mini-lathe has a 3/4-inch chuck thread, allowing you to securely hold and cut many different sizes of material.

- Accuracy: Check that the mini-lathe is accurately aligned, has a stable base, and has a dial indicator gauge. This will help ensure the accuracy of your projects.

- Tools: Make sure you buy a mini-lathe with at least three different cutting tools and tool holders. This will make it easier to complete varied projects.

- Accessories: Make sure that the mini-lathe you choose comes with the necessary accessories, such as a face plate, drive center, live center, and dust guard.

- Durability: Look for a mini-lathe that is made from a durable material, such as cast iron, so it will last for years to come.

What are the capabilities of a mini-lathe?

A mini-lathe is a machine tool that provides high precision machining capabilities on smaller pieces of material, such as metal, plastic, and wood. Mini-lathes are capable of performing a wide variety of operations, such as turning, facing, boring, drilling, reaming, grooving, knurling, and thread cutting. They are used for applications such as manufacturing small parts, diecasting, prototype work, and hobbyist projects.

Mini-lathes feature a bedway, headstock, tailstock, and other components to operate effectively. The bedway supports the workpiece, allowing for proper alignment and for the operator to control the machining motion. The headstock houses the spindle and motor, which move and rotate the chuck or collet to hold the workpiece. The tailstock moves along the bedway, providing support to the workpiece while the spindle cuts.

Mini-lathes have several capabilities. Turning is one of the most common operations performed on a mini-lathe. The process utilizes the headstock spindle and a cutting tool held in the chuck or collet to shape the workpiece, such as to create cylindrical shapes. The mini-lathe can also do facing, which is machining the ends of a cylindrical part to make them flat and perpendicular, as well as boring, which is enlarging an existing hole in the workpiece.

Additionally, the mini-lathe is capable of various other operations. It can perform reaming, which is the process of enlarging and finishing a hole to a precise size and shape. It can also produce grooves, knurling, and threading. Knurling creates a pattern of ridges on the exterior of the workpiece, while threading converts plain surfaces into threads of a specific size and pitch.

The mini-lathe is an invaluable machine tool for tasks ranging from simple hobby projects to precision prototype work. It provides a wide range of capabilities in a compact and cost-effective form, while maintaining accuracy and precision.

How much should i expect to pay for a mini lathe?

The cost of a mini lathe can vary widely depending on its size and features, but you can expect to pay anywhere between $100 and $1000 for a basic mini lathe. Small, lightweight mini lathes that are most suitable for light hobby work and occasional use can be found in the $100 to $200 price range. Mid-range lathes with heavier construction, more features, and better precision can range from $200 to $500.

Higher-end mini lathes with all the bells and whistles can run from $500 to $1,000. When deciding which mini lathe to buy, it is important to consider your budget, the type of work you will be doing, and the level of accuracy needed.