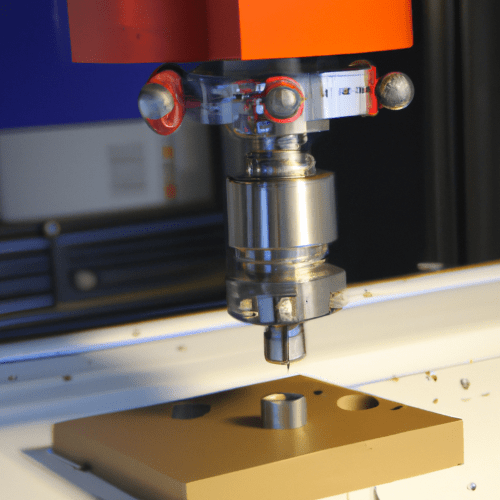

2.5D milling is a type of CNC (Computer Numerical Control) machining process that uses a cutting tool to remove material from a workpiece in two-dimensional (2D) and three-dimensional (3D) shapes. It is a type of milling process that is used to create complex shapes and features on a workpiece. The cutting tool is moved in a linear direction along the X, Y, and Z axes to create the desired shape.

2.5D milling is a subtractive manufacturing process, meaning that material is removed from the workpiece to create the desired shape. The cutting tool is typically a rotating end mill, which is a type of milling cutter. The end mill is moved in a linear direction along the X, Y, and Z axes to create the desired shape. The cutting tool is also moved in a rotational direction to create curved surfaces.

2.5D milling is used to create complex shapes and features on a workpiece.

What is a 2.5 axis milling machine?

A 2.5 axis milling machine is a type of CNC (Computer Numerical Control) milling machine that is capable of moving in two directions (X and Y axes) and can also rotate around the Z axis. It is a type of machining center that is used to produce parts with complex shapes and features. The 2.5 axis milling machine is capable of performing a variety of operations such as drilling, tapping, reaming, boring, and milling. It is also capable of performing contouring operations, which involve cutting along a curved path.

The 2.5 axis milling machine is a versatile machine that can be used for a variety of applications. It is commonly used in the aerospace, automotive, and medical industries for producing complex parts with intricate shapes and features. It is also used in the production of molds and dies, as well as for producing parts for the electronics industry.

What is a 2.5D machine?

A 2.5D machine is a type of computer-controlled machine tool that is used to create three-dimensional (3D) objects from two-dimensional (2D) materials. It is a type of CNC (Computer Numerical Control) machine that uses a combination of computer-controlled cutting tools and software to create 3D objects from 2D materials. The 2.5D machine is capable of cutting, drilling, milling, and engraving a variety of materials, including wood, metal, plastic, and composites.

The 2.5D machine is different from a 3D printer in that it does not use a 3D printing process to create objects. Instead, it uses a combination of computer-controlled cutting tools and software to create 3D objects from 2D materials. The 2.5D machine is capable of cutting, drilling, milling, and engraving a variety of materials, including wood, metal, plastic, and composites.

What is 2.5D process?

2.5D is a process used in the manufacturing industry to create three-dimensional objects from two-dimensional materials. It is a combination of traditional 2D machining processes such as milling, drilling, and cutting, and 3D processes such as laser cutting and 3D printing. The process involves taking a flat sheet of material and using a combination of these processes to create a three-dimensional object.

2.5D machining is used in a variety of industries, including automotive, aerospace, medical, and consumer products. It is often used to create complex parts that would be difficult or impossible to create using traditional 2D machining processes. The process is also used to create parts with intricate details, such as those found in medical implants and consumer electronics.

The process begins with a flat sheet of material, which is then cut into the desired shape using a combination of 2D and 3D processes. The material is then machined to create the desired features, such as holes, slots, and other details. The parts are then assembled and finished to create the final product.

What’s the difference between 2.5D and 3D?

2.5D and 3D are both terms used to describe the visual presentation of a 3-dimensional object on a 2-dimensional surface. 2.5D is a term used to describe a 3-dimensional object that has been flattened into a 2-dimensional image. This is done by taking a 3-dimensional object and then using a computer program to flatten it into a 2-dimensional image. This image can then be used in a variety of ways, such as in video games, movies, or other forms of media.

3D, on the other hand, is a term used to describe a 3-dimensional object that has been rendered in a 3-dimensional space. This is done by using a computer program to create a 3-dimensional model of the object, which can then be manipulated and viewed from different angles. This type of 3-dimensional rendering is used in a variety of applications, such as video games, movies, and other forms of media.

What is the difference between 3 axis and 5 axis CNC?

The main difference between 3 axis and 5 axis CNC is the number of axes of motion that the machine is capable of controlling. A 3 axis CNC machine is capable of controlling three axes of motion: the X, Y, and Z axes. These axes are typically used to control the cutting tool’s position in three-dimensional space. A 5 axis CNC machine is capable of controlling five axes of motion: the X, Y, Z, A, and B axes. The A and B axes are typically used to control the orientation of the cutting tool in three-dimensional space. This allows for more complex machining operations, such as drilling, milling, and tapping, to be performed in a single setup. Additionally, 5 axis CNC machines are capable of producing parts with more complex geometries than 3 axis CNC machines.

What can a 3 axis CNC machine do?

A 3 axis CNC machine is a computer numerical control (CNC) machine that is capable of moving in three axes: the X, Y, and Z axes. This type of machine is used for a variety of machining operations, including milling, drilling, and cutting. It is also capable of performing complex operations such as contouring, profiling, and engraving.

The 3 axis CNC machine is capable of producing parts with a high degree of accuracy and repeatability. It is also capable of producing parts with complex shapes and intricate details. The machine is able to move in three directions, allowing it to produce parts with complex geometries.

The 3 axis CNC machine is also capable of performing a variety of operations, such as drilling, tapping, reaming, and threading. It is also capable of performing operations such as grinding, polishing, and deburring. The machine is also capable of performing operations such as welding, soldering, and brazing.

What is preparatory function?

The preparatory function is a type of executive function that helps us to plan and prepare for upcoming tasks or events. It is the ability to plan ahead, anticipate future needs, and organize our thoughts and actions in order to achieve a goal. It is an important part of our cognitive functioning and helps us to be successful in our daily lives.

The preparatory function involves a number of different skills, such as goal setting, problem solving, decision making, and time management. It also involves the ability to anticipate potential problems and plan for them in advance. This helps us to be more efficient and effective in our work and daily activities.

The preparatory function is closely related to other executive functions, such as working memory, cognitive flexibility, and inhibitory control. Working memory helps us to remember and process information, while cognitive flexibility allows us to switch between tasks and adjust our plans as needed. Inhibitory control helps us to resist distractions and stay focused on our goals. All of these skills work together to help us plan and prepare for upcoming tasks and events.

Does solidworks have cam?

Yes, Solidworks does have CAM (Computer Aided Manufacturing) capabilities. Solidworks CAM is a powerful, integrated CAM system that allows users to quickly and easily program CNC (Computer Numerical Control) machines directly from Solidworks 3D CAD models. Solidworks CAM is fully integrated with the Solidworks 3D CAD environment, allowing users to quickly and easily create CNC programs for a variety of CNC machines, including milling, turning, and multi-axis machines. Solidworks CAM also includes a variety of powerful features, such as automatic feature recognition, toolpath optimization, and collision detection. With Solidworks CAM, users can quickly and easily create CNC programs for a variety of CNC machines, allowing them to quickly and easily produce high-quality parts.