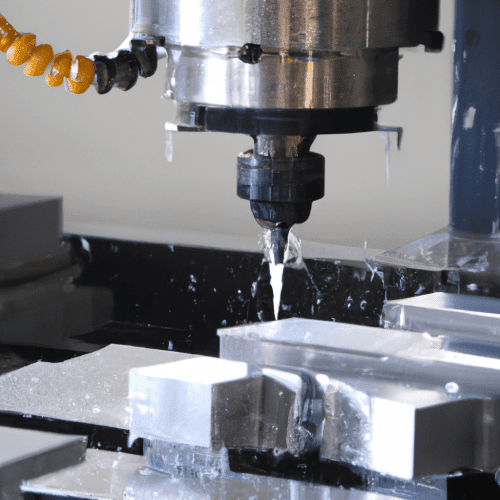

A CNC (Computer Numerical Control) milling machine is a type of computer-controlled machine tool that uses a rotating cutting tool to remove material from a workpiece. The cutting tool is typically a rotating cylindrical tool, such as a drill bit, end mill, or router bit. The cutting tool is mounted on a spindle that is driven by a motor, and the workpiece is mounted on a table that is moved in three axes (X, Y, and Z) to position the cutting tool relative to the workpiece.

The CNC milling machine is programmed using a computer-aided manufacturing (CAM) software package. The CAM software is used to create a tool path, which is a set of instructions that tells the machine how to move the cutting tool in order to create the desired shape. The CAM software also allows the user to specify the cutting speed, feed rate, and other parameters that will affect the quality of the finished product.

Once the tool path is created, the CNC milling machine is ready to begin machining. The machine will move the cutting tool along the tool path, cutting away material from the workpiece as it goes. The cutting tool is typically moved in a series of linear and circular motions, depending on the shape of the workpiece. The cutting tool is also moved in a variety of speeds and depths, depending on the material being machined and the desired finish.

The CNC milling machine is capable of producing very precise and intricate shapes, and is used in a variety of industries, including aerospace, automotive, and medical. It is also used to create custom parts for a variety of applications.

What is CNC machining and how does it work?

CNC (Computer Numerical Control) machining is a manufacturing process that uses computer-controlled machines to shape and cut materials into a desired shape or size. It is a subtractive manufacturing process, meaning that material is removed from a workpiece to create the desired shape or size. CNC machining is used to create a wide variety of products, from medical implants to aerospace components.

The process begins with a CAD (Computer Aided Design) file, which is a digital representation of the desired product. This file is then loaded into a CNC machine, which is a computer-controlled machine that is programmed to move the cutting tool in a specific pattern. The cutting tool is usually a drill bit, router bit, or end mill, and is used to cut away material from the workpiece. The CNC machine is programmed to move the cutting tool in a specific pattern, which is determined by the CAD file. The cutting tool is then moved in a series of linear and rotational motions to create the desired shape or size.

How does a milling machine work?

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to shape and form the material into a variety of different shapes and sizes. The milling machine is capable of cutting a wide variety of materials, including metals such as aluminum, brass, and steel, as well as plastics and other non-metallic materials.

The milling machine works by using a rotating cutting tool to shape and form the material. The cutting tool is typically a multi-point cutting tool, such as an end mill, which is capable of cutting in multiple directions. The cutting tool is held in a spindle, which is connected to a motor that rotates the cutting tool at a high speed. The cutting tool is then moved in a linear direction along the material, cutting away material as it moves.

What are the basics of CNC milling?

CNC (Computer Numerical Control) milling is a machining process that uses computer-controlled cutting tools to shape a workpiece. It is a type of subtractive manufacturing process, where material is removed from a workpiece to create a desired shape or finish. CNC milling is a versatile process that can be used to create a wide variety of shapes and components, from simple to complex.

The basic components of a CNC milling machine include the cutting tool, the workpiece, the spindle, the table, and the controller. The cutting tool is the part of the machine that actually cuts the material. It is usually a rotating cutting tool, such as an end mill or drill bit. The workpiece is the material that is being machined. The spindle is the part of the machine that holds and rotates the cutting tool. The table is the part of the machine that holds the workpiece in place. The controller is the part of the machine that controls the movement of the cutting tool and the speed of the spindle.

Do CNC machines require any programming?

Yes, CNC machines do require programming. CNC stands for Computer Numerical Control, and the programming is what allows the machine to be controlled by a computer. The programming is typically done using a language called G-code, which is a numerical control programming language. G-code is used to tell the machine what type of motion to perform, what speed to move at, what tools to use, and other instructions. The programming is usually done using a CAD/CAM software package, which allows the user to create a 3D model of the part they want to make and then generate the G-code instructions from that model. Once the G-code is generated, it is loaded into the CNC machine and the machine is ready to start machining the part.

How is CNC machine controlled?

CNC machines are controlled by a computer program that is written in a specific language. The program is loaded into the machine’s memory and then the machine is instructed to execute the program. The program contains instructions for the machine to move the cutting tool in a specific direction, at a specific speed, and with a specific amount of force. The program also contains instructions for the machine to adjust the cutting tool’s position and orientation in order to create the desired shape. The program can also be used to control the speed and force of the cutting tool, as well as the speed and force of the machine itself. The program can also be used to control the temperature of the cutting tool, as well as the temperature of the machine itself. The program can also be used to control the amount of lubrication that is used on the cutting tool, as well as the amount of lubrication that is used on the machine itself. Finally, the program can also be used to control the amount of time that the machine is running, as well as the amount of time that the machine is idle.

What is G code in CNC?

G code is a programming language used to control automated machine tools such as CNC machines. It is a language that is used to tell the machine what to do and how to do it. G code is used to create a program that will control the machine’s movements and operations. It is a language that is used to create a set of instructions that the machine can understand and execute. G code is used to control the motion of the machine, the speed of the machine, the feed rate, the cutting tool, and other aspects of the machine’s operation. G code is also used to control the machine’s spindle speed, coolant, and other machine functions. G code is a language that is used to create a program that will control the machine’s movements and operations. It is a language that is used to create a set of instructions that the machine can understand and execute. G code is used to control the motion of the machine, the speed of the machine, the feed rate, the cutting tool, and other aspects of the

How does a CNC lathe machine work?

A CNC lathe machine is a type of automated lathe that is controlled by a computer program. It is used to produce precise parts with a high degree of accuracy and repeatability. The CNC lathe machine works by taking a blank piece of material, such as metal or wood, and using a cutting tool to shape it into the desired shape. The cutting tool is mounted on a spindle that is driven by a motor. The motor is controlled by a computer program that is programmed with the desired cutting parameters.

The CNC lathe machine is programmed with the desired cutting parameters, such as the speed of the spindle, the depth of the cut, and the type of material being cut. The computer program then sends signals to the motor, which in turn drives the spindle and the cutting tool. The cutting tool is then moved along the material in a precise manner, cutting it into the desired shape.

What is G code and M code?

G code and M code are the two most common programming languages used in computer numerical control (CNC) machines. G code is the programming language used to control the movements of a CNC machine, while M code is the programming language used to control the machine’s auxiliary functions. G code is used to control the motion of the machine, such as the speed, direction, and distance of the tool. It is also used to control the machine’s spindle speed, coolant, and other functions. M code is used to control the machine’s auxiliary functions, such as tool changes, spindle speed changes, and coolant on/off.

G code is a language that is used to control the movements of a CNC machine. It is a numerical control language that is used to control the motion of the machine, such as the speed, direction, and distance of the tool. G code is also used to control the machine’s spindle speed, coolant, and other functions.