Yes, it is possible to mill aluminum. Milling aluminum is a process that involves using a cutting tool to remove material from the surface of a piece of aluminum in order to create a desired shape or finish. The process is similar to other milling processes, such as milling steel or other metals, but the tools and techniques used are different due to the properties of aluminum.

When milling aluminum, the cutting tool must be made of a material that is harder than the aluminum being milled. This is because aluminum is a soft metal and the cutting tool must be able to cut through it without becoming dull or damaged. Common materials used for cutting tools when milling aluminum include high-speed steel, carbide, and diamond.

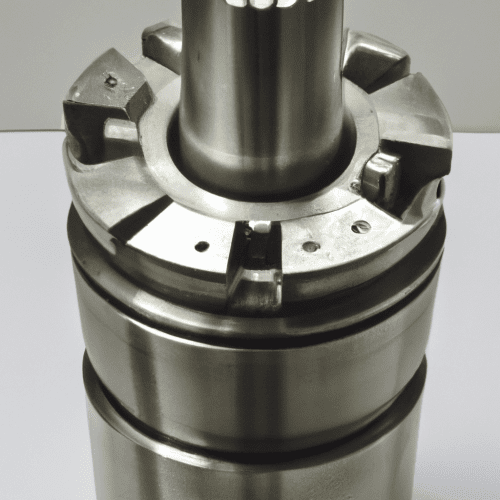

The cutting tool is then mounted in a milling machine, which is a machine that is designed to move the cutting tool in a precise manner in order to create the desired shape or finish. The milling machine is also equipped with a coolant system to keep the cutting tool and the aluminum cool during the milling process.

The milling process begins by clamping the aluminum in place and then using the cutting tool to remove material from the surface. The cutting tool is moved in a precise manner in order to create the desired shape or finish. The amount of material removed and the speed at which the cutting tool is moved will depend on the desired shape or finish.

Once the desired shape or finish has been achieved, the aluminum is then removed from the milling machine and the process is complete. Milling aluminum is a precise process that requires the right tools and techniques in order to achieve the desired results.

Is aluminum hard to mill?

Milling aluminum is a relatively easy process compared to other metals, but it can be challenging depending on the specific alloy being machined. Aluminum is a soft metal, which makes it easier to cut than harder metals such as steel. However, aluminum alloys can be much harder than pure aluminum, and they can be more difficult to machine. The hardness of an aluminum alloy is determined by its composition, and the specific alloy being machined will determine the difficulty of the milling process.

Aluminum is also prone to work hardening, which can make it difficult to machine. Work hardening occurs when the metal is subjected to repeated cutting or machining, which causes the metal to become harder and more resistant to further machining. To prevent work hardening, it is important to use the correct cutting tools and speeds, and to use coolant or lubricant to reduce friction and heat.

In general, aluminum is not difficult to mill, but the specific alloy being machined and the machining conditions can make a big difference in the difficulty of the process. With the right tools and techniques, aluminum can be machined with relative ease.

What does it mean to mill aluminum?

Milling aluminum is a process of removing material from a workpiece in order to shape or finish it. It is typically done with a milling machine, which uses a rotating cutting tool to remove material from the workpiece. The cutting tool is usually a multi-point cutting tool, such as an end mill, which has multiple cutting edges that can be used to cut away material from the workpiece. The milling process can be used to create a variety of shapes and features on the workpiece, such as slots, grooves, and contours. It can also be used to create complex 3D shapes.

The milling process begins by clamping the workpiece into the milling machine. The cutting tool is then positioned and the cutting speed and feed rate are set. The cutting tool is then moved along the workpiece in a series of passes, removing material as it goes. The depth of cut and the number of passes will depend on the desired shape and size of the finished product.

Aluminum is a popular material to mill because it is relatively soft and easy to work with. It is also lightweight and corrosion-resistant, making it a great choice for many applications. Aluminum is also relatively inexpensive, making it a cost-effective choice for many projects.

Milling aluminum requires the use of specialized cutting tools and coolant to prevent the aluminum from melting or becoming damaged during the milling process. It is important to use the correct cutting tools and speeds to ensure that the aluminum is machined correctly and that the finished product is of the highest quality.

What type of cutter is used for milling aluminum?

Milling aluminum requires a specific type of cutter to ensure that the material is cut properly and efficiently. The most common type of cutter used for milling aluminum is an end mill. End mills are designed with flutes that spiral around the cutting edge, allowing for efficient chip removal and a smooth finish. End mills are available in a variety of sizes and shapes, including square, ball, and corner radius, and can be used for a variety of operations, including face milling, shoulder milling, and slotting. Additionally, end mills can be used for both roughing and finishing operations. When selecting an end mill for milling aluminum, it is important to consider the material’s hardness, the depth of the cut, and the desired finish. For example, a high-speed steel end mill is best suited for softer aluminum alloys, while a carbide end mill is better suited for harder aluminum alloys. Additionally, a coated end mill is recommended for aluminum alloys that are prone to galling or welding.

Can you use carbide end mill on aluminum?

Yes, you can use a carbide end mill on aluminum. Carbide end mills are designed to be used on a variety of materials, including aluminum. Carbide end mills are made from a combination of tungsten carbide and cobalt, which makes them extremely hard and durable. This makes them ideal for machining aluminum, as they can withstand the high temperatures and pressures associated with the machining process. When machining aluminum with a carbide end mill, it is important to use the correct cutting parameters. The cutting speed should be kept low to reduce heat buildup, and the feed rate should be adjusted to ensure that the end mill does not overheat. Additionally, it is important to use a lubricant to reduce friction and heat buildup. Using a lubricant will also help to extend the life of the end mill. When using a carbide end mill on aluminum, it is important to use the correct cutting parameters and lubricant to ensure that the end mill does not overheat and that the aluminum is machined correctly.

Why is aluminum difficult to machine?

Aluminum is a relatively soft metal, which makes it difficult to machine. It is also very malleable, meaning it can easily deform under pressure. This makes it difficult to hold in place while machining, as it can easily move or shift. Additionally, aluminum has a low melting point, which means it can easily become overheated during machining. This can cause the aluminum to become gummy and difficult to work with. Finally, aluminum is a very reactive metal, meaning it can easily corrode or oxidize when exposed to air or moisture. This can cause the aluminum to become brittle and difficult to machine. All of these factors make aluminum difficult to machine.

How many flutes does it take to mill aluminum?

Milling aluminum with a flute requires a specific type of flute, known as an end mill. The number of flutes needed to mill aluminum depends on the size and shape of the aluminum being milled, as well as the desired finish. Generally, aluminum is milled with two, three, or four flutes. Two flutes are used for roughing, three flutes are used for semi-finishing, and four flutes are used for finishing. The number of flutes used also depends on the type of aluminum being milled. For example, softer aluminum may require fewer flutes than harder aluminum. Additionally, the type of end mill used can affect the number of flutes needed. For example, a high-performance end mill may require fewer flutes than a standard end mill. Ultimately, the number of flutes needed to mill aluminum depends on the specific application and the desired finish.

Do you need coolant to mill aluminum?

Yes, coolant is necessary when milling aluminum. Coolant helps to reduce friction and heat buildup, which can cause the aluminum to become too hot and cause it to deform or even melt. Coolant also helps to flush away chips and debris that can accumulate during the milling process, which can cause the tool to become clogged and cause the milling process to become inefficient. Additionally, coolant helps to lubricate the cutting tool, which can help to extend its life and reduce wear and tear. It is important to use the correct type of coolant for the specific aluminum alloy being milled, as some coolants may not be compatible with certain alloys.

Can you mill aluminum with a router?

Yes, you can mill aluminum with a router, but it is important to take certain precautions to ensure that the job is done safely and correctly. First, you should make sure that the router bit you are using is designed for aluminum. This is because aluminum is a softer metal than other materials, and using a bit that is not designed for aluminum can cause it to wear down quickly. Additionally, you should make sure that the router bit is sharp and in good condition, as a dull bit can cause the aluminum to heat up and become damaged. It is also important to use a router with a variable speed control, as this will allow you to adjust the speed of the router to the thickness of the aluminum. Finally, you should use a lubricant when milling aluminum, as this will help to reduce friction and heat buildup. By taking these precautions, you can safely and effectively mill aluminum with a router.

How thin can you mill aluminum?

Milling aluminum is a process that involves using a cutting tool to remove material from a workpiece in order to shape it into a desired shape. The thickness of the aluminum that can be milled depends on a variety of factors, including the type of milling machine being used, the type of aluminum being milled, and the desired end result. Generally speaking, aluminum can be milled to a thickness of 0.005 inches or less.

When milling aluminum, it is important to use the correct cutting tool and cutting parameters. The cutting tool should be made of a material that is harder than the aluminum being milled, such as high-speed steel or carbide. The cutting parameters should be adjusted to ensure that the cutting tool does not become too hot, which can cause the aluminum to become brittle and break. Additionally, the cutting speed should be adjusted to ensure that the aluminum is not being cut too quickly, which can cause the aluminum to become distorted.

The type of aluminum being milled can also affect the thickness that can be achieved. For example, aluminum alloys that are harder and more heat-resistant can be milled to a thinner thickness than softer aluminum alloys. Additionally, the type of milling machine being used can also affect the thickness that can be achieved. For example, a CNC milling machine can typically achieve a thinner thickness than a manual milling machine.

In conclusion, the thickness of aluminum that can be milled depends on a variety of factors, including the type of milling machine being used, the type of aluminum being milled, and the desired end result. Generally speaking, aluminum can be milled to a thickness of 0.005 inches or less.