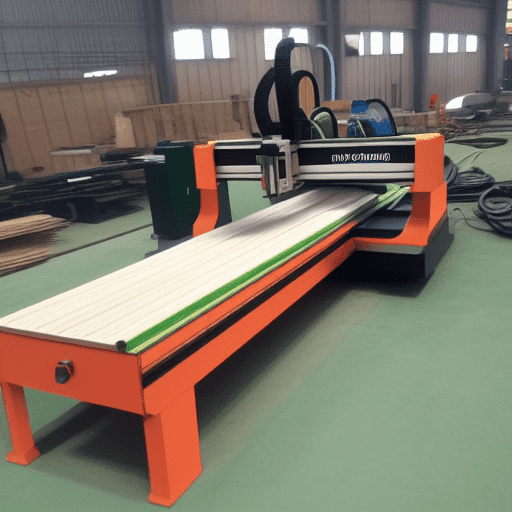

A CNC (Computer Numerical Control) wood machine is a type of automated machine tool that is used to cut and shape wood. It is controlled by a computer program that is programmed to move the cutting tool in a specific pattern and at a specific speed. The CNC wood machine is typically used to create intricate designs and shapes in wood, such as furniture, cabinets, and other wood products.

The CNC wood machine works by using a computer program to control the cutting tool. The program is programmed to move the cutting tool in a specific pattern and at a specific speed. The cutting tool is usually a router, which is a type of motorized cutting tool that is used to cut and shape wood. The router is connected to the CNC machine and is controlled by the computer program.

The computer program is programmed to move the cutting tool in a specific pattern and at a specific speed. The cutting tool is moved in a three-dimensional pattern, which is determined by the computer program. The cutting tool is moved in a specific direction and at a specific speed, which is determined by the computer program. The cutting tool is also programmed to cut the wood at a specific depth and at a specific angle.

The CNC wood machine is also equipped with a variety of sensors that are used to monitor the cutting process. These sensors are used to detect any problems with the cutting process, such as the cutting tool becoming dull or the wood becoming too thick. The sensors are also used to detect any changes in the cutting process, such as the cutting tool becoming too hot or the wood becoming too soft.

Once the cutting process is complete, the CNC wood machine is programmed to move the cutting tool back to its original position. The cutting tool is then removed from the CNC machine and the wood is ready to be used. The CNC wood machine is a very efficient and precise way to cut and shape wood.

Can a CNC machine cut wood?

Yes, a CNC (Computer Numerical Control) machine can be used to cut wood. CNC machines are computer-controlled tools that are used to shape and cut materials such as wood, metal, plastic, and foam. They are used in a variety of industries, including woodworking, metalworking, and manufacturing.

CNC machines are capable of cutting wood with precision and accuracy. They can be used to cut intricate shapes and patterns, as well as to create smooth, even edges. CNC machines are also capable of cutting multiple pieces of wood at once, which can save time and money.

CNC machines are typically used in woodworking applications such as furniture making, cabinetry, and millwork. They can be used to cut a variety of wood types, including hardwoods, softwoods, and engineered woods. CNC machines can also be used to cut wood with a variety of tools, such as saw blades, router bits, and end mills.

Can a CNC router cut hardwood?

Yes, a CNC router can cut hardwood. CNC routers are computer-controlled machines that use a spinning router bit to cut out shapes and designs from a variety of materials, including hardwood. The router bit is usually made of carbide, a material that is very hard and durable, making it ideal for cutting hardwood. The CNC router can be programmed to cut out intricate shapes and designs with precision and accuracy. The speed and accuracy of the CNC router make it an ideal tool for cutting hardwood.

When cutting hardwood with a CNC router, it is important to use the right router bit for the job. Different router bits are designed for different materials, and the wrong bit can cause the wood to splinter or chip. It is also important to use the right cutting speed and feed rate for the material being cut. Too slow of a speed can cause the wood to burn, while too fast of a speed can cause the wood to splinter. The feed rate should also be adjusted to ensure that the router bit is cutting at the right depth.

How does a CNC router work simple?

A CNC router is a computer-controlled cutting machine used to cut a variety of materials, such as wood, plastic, foam, and aluminum. It is a type of machining process that uses a cutting tool to move along a predetermined path, guided by a computer program. The cutting tool is usually a router bit, which is a rotating cutting tool that is mounted on a spindle. The spindle is driven by a motor, which is controlled by the computer program.

The computer program is used to control the movement of the cutting tool, as well as the speed and depth of the cut. The program can also be used to control the feed rate of the cutting tool, which is the speed at which the cutting tool moves along the predetermined path. The program can also be used to control the cutting pressure, which is the amount of force applied to the material being cut.

What materials can you cut with a CNC router?

A CNC router is a computer-controlled cutting machine used to cut a variety of materials, including wood, plastic, foam, aluminum, brass, copper, and steel. It is a versatile tool that can be used to create intricate shapes and designs with precision and accuracy. The type of material that can be cut with a CNC router depends on the type of router and the type of cutting tool used.

Wood is the most common material used with a CNC router. It can be used to create furniture, cabinetry, signs, and other woodworking projects. The router can be used to cut intricate shapes and designs with precision and accuracy. The type of wood that can be cut with a CNC router depends on the type of router and the type of cutting tool used.

Plastic is another material that can be cut with a CNC router. It is often used to create signs, displays, and other plastic products. The type of plastic that can be cut with a CNC router depends on the type of router and the type of cutting tool used.

Is a CNC machine worth it?

Whether or not a CNC machine is worth it depends on a variety of factors, including the size of the business, the type of work being done, and the budget available. For businesses that require a high level of precision and accuracy, a CNC machine can be a great investment. CNC machines are capable of producing parts with a high degree of accuracy and repeatability, which can be beneficial for businesses that require a high level of precision in their work. Additionally, CNC machines can be programmed to produce parts quickly and efficiently, which can save time and money in the long run.

However, CNC machines can be expensive to purchase and maintain, and they require a certain level of expertise to operate. Additionally, CNC machines are not suitable for all types of work, and they may not be necessary for businesses that do not require a high level of precision. Therefore, it is important to consider the type of work being done and the budget available before investing in a CNC machine.

How deep can a CNC cut?

The depth of cut that a CNC machine can achieve is determined by a variety of factors, including the size and power of the machine, the type of material being cut, and the type of cutting tool being used. Generally speaking, CNC machines are capable of cutting to depths of up to several inches, depending on the material and the cutting tool. For example, a CNC router with a 1/4 end mill can typically cut to a depth of up to 1/2 in soft materials such as wood, while a CNC mill with a 1/2 end mill can cut to a depth of up to 1 in harder materials such as aluminum. Additionally, CNC machines can be equipped with special tools such as drill bits and countersinks that can cut to even greater depths. Ultimately, the depth of cut that a CNC machine can achieve is limited only by the size and power of the machine, the type of material being cut, and the type of cutting tool being used.

What can you do with a CNC wood machine?

A CNC (Computer Numerical Control) wood machine is a type of automated machine tool that is used to cut, shape, and finish wood products. It is a versatile tool that can be used for a variety of applications, including cutting, drilling, routing, engraving, and milling. With a CNC wood machine, you can create intricate designs and shapes with precision and accuracy.

One of the most common uses of a CNC wood machine is for cutting and shaping wood. The machine can be used to cut wood into various shapes and sizes, such as circles, squares, rectangles, and other shapes. It can also be used to create intricate designs, such as inlays, carvings, and engravings. The machine can also be used to drill holes in wood, allowing for the installation of hardware, such as hinges and screws.

Another common use of a CNC wood machine is for routing. This is the process of cutting grooves and channels into wood. This is often used to create decorative edges, such as on furniture or cabinetry.

How much does CNC cost?

The cost of CNC (Computer Numerical Control) machines can vary greatly depending on the type of machine, its size, and the complexity of the parts it is designed to produce. Generally speaking, the cost of a CNC machine can range from a few thousand dollars for a basic desktop model to hundreds of thousands of dollars for a large industrial model. The cost of the machine itself is only part of the equation, however, as there are also additional costs associated with the machine such as software, tooling, and maintenance.

Software is an important part of CNC machines, as it is used to program the machine to produce the desired parts. The cost of the software can range from a few hundred dollars for basic programs to several thousand dollars for more complex programs. Additionally, the cost of tooling must also be taken into account. Tooling is the cutting tools, such as drills and end mills, that are used to produce the parts. The cost of tooling can range from a few hundred dollars for basic tools to several thousand dollars for more complex tools.

What do I need to know before buying a CNC machine?

Before buying a CNC machine, it is important to consider a few key factors. First, you should consider the size and type of CNC machine that you need. Depending on the size and type of material you plan to work with, you may need a larger or smaller machine. Additionally, you should consider the type of CNC machine that you need. There are several types of CNC machines, including milling machines, lathes, and routers. Each type of machine has its own advantages and disadvantages, so it is important to research the different types and decide which one is best for your needs.

Next, you should consider the features of the CNC machine. Different machines have different features, such as spindle speed, tooling, and software compatibility. It is important to research the features of the machine and make sure that it has the features you need. Additionally, you should consider the cost of the machine.

How long does it take to learn CNC?

Learning CNC can take anywhere from a few weeks to a few months, depending on the individual’s prior experience and the complexity of the CNC machine being used. For those with no prior experience, it is recommended to start with a basic CNC machine and learn the fundamentals of CNC programming. This includes understanding the basic concepts of CNC programming, such as G-code, tool paths, and machine setup. Once the basics are understood, the individual can then move on to more complex CNC machines and programming.

For those with some prior experience, the learning process can be accelerated. This is because the individual will already have a basic understanding of CNC programming and can focus on the more complex aspects of the machine. However, even with prior experience, it is still recommended to start with a basic CNC machine and work up to the more complex machines.

In addition to learning the basics of CNC programming, it is also important to understand the safety protocols associated with CNC machines.