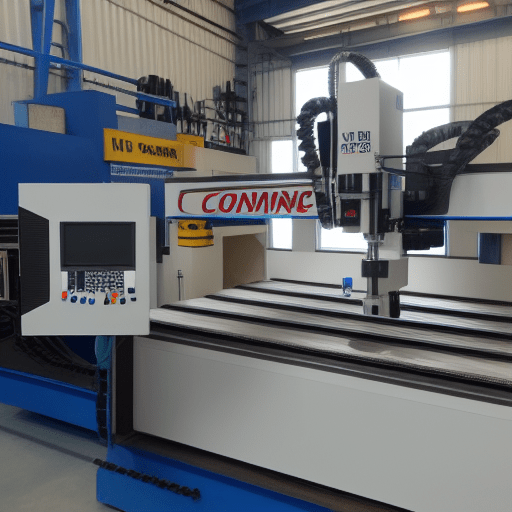

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. CNC machines are used to produce parts with high precision and accuracy, and can be used to perform a variety of operations, including drilling, milling, turning, and grinding. The number of operations a CNC machine can perform depends on the type of machine and the tools it is equipped with.

For example, a CNC milling machine can be used to perform a variety of operations, including drilling, reaming, counterboring, countersinking, and tapping. It can also be used to perform milling operations, such as face milling, shoulder milling, and slotting. A CNC lathe can be used to perform turning operations, such as facing, grooving, and threading. A CNC router can be used to perform routing operations, such as cutting, engraving, and carving.

In addition to these operations, CNC machines can also be used to perform other operations, such as welding, heat treating, and surface finishing. The number of operations a CNC machine can perform is limited only by the type of machine and the tools it is equipped with. For example, a CNC machine equipped with a 3-axis milling head can perform up to three operations at once, while a 5-axis milling head can perform up to five operations at once.

Overall, the number of operations a CNC machine can perform is dependent on the type of machine and the tools it is equipped with. A CNC machine can be used to perform a variety of operations, including drilling, milling, turning, grinding, welding, heat treating, and surface finishing. The number of operations a CNC machine can perform is limited only by the type of machine and the tools it is equipped with.

Which operation is done in CNC machine?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement and operation of the machine. CNC machines are used to perform a variety of operations, including drilling, milling, turning, and grinding. The CNC machine is programmed with a series of instructions that tell it how to move and operate the machine. The instructions are written in a computer language called G-code, which is a language specifically designed for CNC machines. The G-code instructions tell the machine how to move the cutting tool, how fast to move it, and how deep to cut into the material. The CNC machine can also be programmed to perform other operations, such as tapping, threading, and reaming. CNC machines are used in a variety of industries, including automotive, aerospace, medical, and electronics. They are used to produce parts for cars, airplanes, medical devices, and electronic components. CNC machines are also used to produce custom parts for a variety of applications.

What are the steps in CNC process?

CNC (Computer Numerical Control) is a process used in manufacturing that involves the use of computer-controlled machines to cut and shape materials into desired shapes and sizes. The CNC process involves several steps, including programming, setup, machining, and inspection.

Programming: The first step in the CNC process is programming. This involves creating a program that will tell the machine what to do. The program is typically written in a language such as G-code or CNC-specific languages. The program will include instructions for the machine, such as the type of material to be cut, the size and shape of the finished product, and the speed and depth of the cut.

Setup: Once the program is written, the next step is to set up the machine. This involves loading the program into the machine, setting up the tools and materials, and ensuring that the machine is properly calibrated.

How many controls does a CNC machine have?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses a computer program to control its movements and operations. The number of controls on a CNC machine can vary depending on the type of machine and its intended use. Generally, CNC machines have three main controls: the program control, the machine control, and the operator control.

The program control is the main control of the CNC machine, and it is responsible for controlling the machine’s movements and operations. This control is typically programmed using a computer language such as G-code, which is a language specifically designed for CNC machines. The program control is responsible for controlling the machine’s movements and operations, and it is typically programmed using a computer language such as G-code.

What is milling machine operation?

Milling machine operation is the process of using rotary cutters to remove material from a workpiece by advancing or feeding in a direction at an angle with the axis of the tool. It covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes in industry and machine shops today.

The basic idea of milling machine operation is that material is fed into the workpiece, which is then cut away by a rotating cutting tool. The cutting tool is usually a multi-point cutting tool, such as an end mill, which is capable of cutting in multiple directions. The cutting tool is held in a spindle, which is rotated by a motor. The spindle is then moved in various directions, either manually or by computer numerical control (CNC), to cut away material from the workpiece.

What are the machining operations?

Machining operations are a type of manufacturing process that involve the use of specialized tools and machines to shape and cut materials into desired shapes and sizes. Machining operations are used to create parts and components for a wide variety of products, from medical devices to automotive parts. Common machining operations include turning, milling, drilling, grinding, sawing, and broaching.

Turning is a machining process that involves rotating a workpiece on a lathe while a cutting tool is used to remove material from the workpiece. This process is used to create cylindrical parts with a uniform diameter and shape.

Milling is a machining process that involves using a rotating cutting tool to remove material from a workpiece. This process is used to create flat surfaces, slots, grooves, and other features on the workpiece.

Drilling is a machining process that involves using a rotating drill bit to create holes in a workpiece. This process is used to create holes for fasteners, such as screws and bolts, as well as for other purposes.

What is the control system of CNC machine?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses a computer program to control its movements and operations. The control system of a CNC machine is the combination of hardware and software components that enable the machine to interpret and execute instructions from a CNC program.

The hardware components of a CNC control system include the CNC controller, the servo motors, the drive system, and the machine tool. The CNC controller is the main component of the control system and is responsible for interpreting the CNC program and sending the appropriate commands to the servo motors. The servo motors are responsible for controlling the movement of the machine tool, while the drive system is responsible for providing the power to the servo motors.

The software components of a CNC control system include the CNC program, the CNC software, and the CNC machine control language. The CNC program is a set of instructions written in a specific language that tells the CNC machine what to do.

How many types of CNC program are there?

There are several different types of CNC programs, each of which is designed to control a different type of CNC machine. The most common types of CNC programs are G-code, M-code, and conversational programming. G-code is the most widely used type of CNC program and is used to control the motion of the machine, as well as the speed and feed rate. M-code is used to control the machine’s auxiliary functions, such as coolant, spindle speed, and tool changes. Conversational programming is a type of CNC programming that is used to create simple parts quickly and easily. It is a graphical user interface (GUI) that allows the user to create a part by selecting the desired features from a menu. Other types of CNC programs include parametric programming, macro programming, and adaptive control programming. Parametric programming is used to create parts with complex shapes and features. Macro programming is used to create programs that can be reused for multiple parts. Adaptive control programming is used to create programs that can adjust to changing conditions in the machine.

How many operations are in a milling machine?

Milling machines are a type of machine tool used for precision shaping and cutting of metal and other materials. They are typically used for machining parts to precise sizes and shapes. The number of operations that a milling machine can perform depends on the type of milling machine being used. Generally, there are two main types of milling machines: vertical and horizontal.

Vertical milling machines are the most common type and are used for a variety of operations. They are capable of cutting, drilling, boring, and shaping metal and other materials. They can also be used for milling complex shapes and contours. The number of operations that a vertical milling machine can perform is limited only by the size and complexity of the workpiece.

Horizontal milling machines are also used for a variety of operations. They are capable of cutting, drilling, boring, and shaping metal and other materials. They can also be used for milling complex shapes and contours.

What are different types of milling operations?

Milling is a machining process that uses a rotating cutting tool to shape and form materials such as metal, wood, and plastic. It is one of the most commonly used processes in manufacturing and is used to create a variety of shapes and sizes. There are several different types of milling operations, each with its own set of advantages and disadvantages.

The most common type of milling operation is end milling, which is used to create flat surfaces, slots, and contours. End milling is typically used to create parts with complex shapes and features, such as those found in automotive and aerospace components. It is also used to create intricate patterns and designs on the surface of a workpiece.

Face milling is another type of milling operation that is used to create flat surfaces. It is typically used to create large, flat surfaces on a workpiece, such as the top of a table or the side of a block. Face milling is often used in the production of large parts, such as engine blocks and cylinder heads.

What is CNC lathe machine operation?

CNC lathe machine operation is a process of machining a workpiece on a lathe machine using computer numerical control (CNC). CNC lathe machines are automated lathes that are programmed to perform specific operations on a workpiece. The CNC lathe machine operator is responsible for programming the machine to perform the desired operations, setting up the machine, and monitoring the machine during the machining process.

The CNC lathe machine operator must be familiar with the machine’s programming language and the various operations that can be performed on the machine. The operator must also be familiar with the various cutting tools and materials that can be used on the machine. The operator must also be able to read and interpret blueprints and drawings to ensure that the machine is set up correctly and that the desired operations are performed correctly.

Once the machine is set up, the operator will enter the program into the machine’s control panel. The program will tell the machine what operations to perform on the workpiece. The operator will then monitor the machine as it performs the operations.

How many axis are there in CNC machine?

CNC (Computer Numerical Control) machines are automated machines that are used to control the movement of tools and parts in a variety of industrial processes. The number of axes in a CNC machine depends on the type of machine and the application it is used for. Generally, CNC machines have three, four, five, or six axes.

The three-axis CNC machine is the most common type and is used for milling, drilling, and tapping operations. It has three linear axes of motion (X, Y, and Z) that allow the machine to move in three directions. The four-axis CNC machine adds an additional rotary axis (A) that allows the machine to rotate the tool or part in a fourth direction. The five-axis CNC machine adds a second rotary axis (B) that allows the machine to rotate the tool or part in a fifth direction. The six-axis CNC machine adds a third rotary axis (C) that allows the machine to rotate the tool or part in a sixth direction.