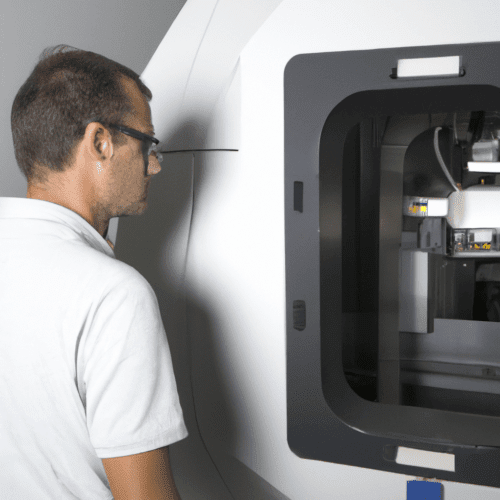

CNC machining can be a stressful job, depending on the individual and the specific job. It requires a great deal of precision and accuracy, and mistakes can be costly. The job also requires a great deal of concentration and focus, and the operator must be able to work quickly and efficiently. Additionally, the operator must be able to troubleshoot any problems that arise, and must be able to make quick decisions in order to keep the machine running smoothly. The operator must also be able to work with a variety of materials, and must be able to adjust the machine settings accordingly.

Overall, CNC machining can be a very demanding job, and it requires a great deal of skill and knowledge. It can be stressful, especially when deadlines are tight and mistakes can be costly. However, with the right training and experience, it can be a rewarding and satisfying job.

Is CNC work difficult?

CNC work can be difficult depending on the complexity of the job and the skill level of the operator. CNC machines are computer-controlled tools that are used to cut, shape, and form materials into a desired shape or design. The operator must be able to understand the programming language used to control the machine, as well as the principles of machining and the materials being used. The operator must also be able to troubleshoot any issues that may arise during the machining process.

CNC machining requires a great deal of precision and accuracy, and the operator must be able to make adjustments to the machine as needed. The operator must also be able to read and interpret blueprints and other technical drawings in order to ensure that the finished product meets the desired specifications.

In addition to the technical skills required to operate a CNC machine, the operator must also have good problem-solving skills and be able to think critically in order to troubleshoot any issues that may arise. The operator must also be able to work quickly and efficiently in order to meet deadlines.

How hard is it to learn to be a machinist?

Learning to be a machinist can be a challenging but rewarding experience. It requires a combination of technical knowledge, manual dexterity, and problem-solving skills. To become a machinist, you must have a good understanding of mathematics, physics, and engineering principles. You must also be able to read and interpret blueprints and schematics. Additionally, you must be able to use a variety of tools and machines, such as lathes, milling machines, and grinders.

The amount of time it takes to learn to be a machinist depends on the individual and the type of training they receive. For those who have a background in engineering or mathematics, the learning curve may be shorter. However, for those who are starting from scratch, it may take longer to learn the necessary skills.

In addition to technical knowledge, machinists must also have good problem-solving skills. They must be able to troubleshoot and diagnose problems with machines and tools. They must also be able to think critically and come up with creative solutions to complex problems.

Is CNC physically demanding?

CNC (Computer Numerical Control) is a type of machining process that uses computer-controlled machines to shape and cut materials. It is a highly precise and automated process that requires minimal physical effort from the operator. However, it is important to note that CNC machining does require some physical effort, as the operator must be able to move the machine and adjust the settings as needed. Additionally, the operator must be able to lift and move heavy materials, as well as be able to stand for long periods of time.

Overall, CNC machining is not a physically demanding job, but it does require some physical effort from the operator. It is important to note that the operator must be able to move the machine and adjust the settings as needed, as well as be able to lift and move heavy materials. Additionally, the operator must be able to stand for long periods of time.

Is machining difficult?

Machining can be a difficult process, depending on the complexity of the part being machined and the skill level of the machinist. Machining involves the use of cutting tools to shape and form a workpiece, and requires a high level of precision and accuracy. It also requires a good understanding of the material being machined, as well as the tools and techniques used to achieve the desired result. Machining can be a time-consuming process, and requires a great deal of patience and practice to become proficient. Additionally, machining can be dangerous, as it involves the use of sharp tools and machinery that can cause serious injury if not used properly. For these reasons, machining is not a task to be taken lightly, and requires a great deal of skill and knowledge to be successful.

Is CNC is a good career?

CNC (Computer Numerical Control) is a great career choice for those who are interested in working with machines and technology. CNC is a type of machining process that uses computer-controlled machines to cut and shape materials into desired shapes and sizes. CNC machinists use computer-aided design (CAD) software to create 3D models of the parts they are creating, and then use CNC machines to cut and shape the materials into the desired shape. CNC machinists must be highly skilled in both the software and the machines they use, as well as have a good understanding of the materials they are working with.

CNC machinists are in high demand in many industries, including automotive, aerospace, medical, and manufacturing. CNC machinists can work in a variety of settings, from large factories to small shops. The job outlook for CNC machinists is expected to remain strong, as the demand for skilled machinists is expected to continue to grow.

How long does it take to learn CNC?

Learning CNC (Computer Numerical Control) can take anywhere from a few days to several months, depending on the complexity of the CNC machine and the level of expertise the learner is aiming for. For someone with no prior experience, it can take several weeks to learn the basics of CNC programming and operation. This includes understanding the fundamentals of CNC programming, such as G-code, and the basics of CNC machine operation, such as setting up the machine, loading the program, and running the program.

For someone with some prior experience, the learning process can be accelerated. With a basic understanding of CNC programming and operation, it can take a few days to a few weeks to become proficient in the operation of a CNC machine. This includes understanding the more advanced aspects of CNC programming, such as toolpaths and offsets, as well as the more advanced aspects of CNC machine operation, such as troubleshooting and maintenance.

Is CNC machining a dying trade?

No, CNC machining is not a dying trade. In fact, it is a growing field that is becoming increasingly important in the manufacturing industry. CNC machining is a process that uses computer numerical control (CNC) machines to cut and shape materials into precise shapes and sizes. It is used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC machining is a highly skilled trade that requires a great deal of knowledge and experience.

CNC machining is becoming increasingly important in the manufacturing industry due to its ability to produce high-quality parts with a high degree of accuracy and repeatability. CNC machines are able to produce parts with tight tolerances and complex geometries that would be difficult or impossible to produce with traditional machining methods. Additionally, CNC machining is often more cost-effective than traditional machining methods, as it requires less labor and fewer tools.

CNC machining is also becoming increasingly important in the medical industry, as it is used to create implants and prosthetics with precise dimensions and shapes.

Are CNC machinists happy?

The answer to this question is not a simple yes or no. The level of happiness of CNC machinists can vary greatly depending on a variety of factors. Generally speaking, CNC machinists tend to be satisfied with their jobs, as they are able to work with their hands and use their technical skills to create products. They also often enjoy the challenge of problem-solving and the satisfaction of seeing a project through to completion. Additionally, CNC machinists often have the opportunity to work with a variety of materials and machines, which can be rewarding.

However, CNC machinists may not be as happy if they are not adequately compensated for their work, or if they are not given the opportunity to advance in their career. Additionally, CNC machinists may become frustrated if they are not given the proper training or resources to do their job effectively. Furthermore, CNC machinists may become dissatisfied if they are not given the opportunity to work on interesting projects or if they are not given the opportunity to use their creativity.

Is being a machinist boring?

No, being a machinist is not boring. In fact, it can be a very rewarding and interesting career. Machinists are responsible for creating and maintaining precision parts and tools used in a variety of industries, from automotive to aerospace. This requires a great deal of skill and knowledge, as well as a keen eye for detail. Machinists must be able to read and interpret blueprints, use a variety of tools and machines, and understand the principles of mathematics and physics.

The work of a machinist can be both challenging and rewarding. Machinists must be able to think critically and solve problems quickly and accurately. They must also be able to work with a variety of materials, from metal to plastic, and be able to adjust their techniques to the material they are working with. This requires a great deal of creativity and problem-solving skills.

The work of a machinist can also be very satisfying. Machinists get to see the results of their work in the form of precision parts and tools that are used in a variety of industries.

What qualifies a machinist?

A machinist is a skilled tradesperson who operates machine tools to produce precision metal parts. To qualify as a machinist, an individual must have a combination of technical knowledge, manual dexterity, and problem-solving skills. Technical knowledge includes an understanding of the principles of machining, such as the properties of metals and the capabilities of various machine tools. Manual dexterity is necessary to operate the machine tools with precision and accuracy. Problem-solving skills are needed to troubleshoot and adjust the machines when necessary.

In addition to these skills, a machinist must also have a good understanding of mathematics, including geometry and trigonometry. This is necessary to calculate the dimensions of the parts being machined and to set up the machines correctly. Machinists must also be able to read and interpret blueprints and other technical drawings.

In order to become a machinist, an individual must typically complete a formal apprenticeship program or a machinist certification program. Apprenticeship programs typically involve a combination of classroom instruction and on-the-job training.

Is machining difficult?

Machining can be a difficult process, depending on the complexity of the part being machined and the skill level of the machinist. Machining involves the use of cutting tools to shape and form a workpiece, and requires a high level of precision and accuracy. It also requires a good understanding of the material being machined, as well as the tools and techniques used to achieve the desired result. Machining can be a time-consuming process, and requires a great deal of patience and practice to become proficient. Additionally, machining can be dangerous, as it involves the use of sharp tools and machinery that can cause serious injury if not used properly. For these reasons, machining is not a task to be taken lightly, and requires a great deal of skill and knowledge to be successful.

How much does CNC machining make?

CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape and cut materials into a desired shape or size. CNC machining is used in a variety of industries, including aerospace, automotive, medical, and consumer products. The amount of money that CNC machining makes depends on a variety of factors, including the type of CNC machine used, the complexity of the job, the materials used, and the number of parts produced.

CNC machining is typically used to produce parts with high precision and accuracy. The cost of CNC machining is determined by the complexity of the job, the materials used, and the number of parts produced. For example, a simple job with a few parts may cost less than a complex job with many parts. The cost of materials used in CNC machining can also vary depending on the type of material used. For example, aluminum is typically more expensive than steel.

How do I get started in CNC machine?

Getting started in CNC machining can be a daunting task, but with the right knowledge and resources, it can be a rewarding and enjoyable experience. The first step is to understand the basics of CNC machining. CNC stands for Computer Numerical Control, and it is a type of machining process that uses computer-controlled machines to cut and shape materials. CNC machines are used to create precision parts and components for a variety of industries, including automotive, aerospace, medical, and consumer products.

Once you have a basic understanding of CNC machining, the next step is to decide which type of CNC machine is best for your needs. There are several types of CNC machines, including milling machines, lathes, routers, and 3D printers. Each type of machine has its own advantages and disadvantages, so it is important to research and understand the capabilities of each type of machine before making a purchase.

Is being a machinist worth it?

Being a machinist can be a very rewarding career choice. It requires a great deal of skill and knowledge, and the potential for job security and financial stability is high. Machinists are responsible for the production of a variety of products, from medical equipment to automotive parts. They use a variety of tools and machines to create precision parts and components, and must be able to read and interpret blueprints and technical drawings.

The job of a machinist can be physically demanding, as it requires standing for long periods of time and working with heavy machinery. It also requires a great deal of concentration and attention to detail, as even the slightest mistake can have serious consequences.

The pay for machinists can vary depending on the industry and the location, but it is generally quite good. According to the Bureau of Labor Statistics, the median annual wage for machinists in the United States was $43,140 in May 2019. This is higher than the median annual wage for all occupations, which was $39,810 in May 2019.

Are machinist in high demand?

Yes, machinists are in high demand. Machinists are skilled workers who use machine tools to create parts and products from raw materials. They are highly sought after in many industries, including automotive, aerospace, medical, and manufacturing. The demand for machinists is expected to remain strong in the coming years due to the increasing need for precision parts and components in a variety of industries.

The Bureau of Labor Statistics (BLS) projects that the number of machinists in the United States will increase by 8% from 2019 to 2029. This is faster than the average for all occupations. The demand for machinists is driven by the need for precision parts and components in a variety of industries. As technology advances, the need for machinists to create parts and products with greater accuracy and precision increases.

In addition to the increasing demand for machinists, the job outlook for machinists is also favorable. The median annual wage for machinists was $42,550 in May 2019, according to the BLS.