The amount of watts in a laser depends on the application for which it is being used. For example, lasers used for medical purposes typically range from 10 to 100 watts, whereas lasers used for industrial purposes may require up to 1,000 watts or more. Therefore, the amount of watts required in a laser is dependent on the specific application for which it is intended.

What Types of Lasers Produce How Many Watts of Power?

There are numerous types of lasers available that produce a wide range of power outputs. Lasers can be classified into two main categories based on their power outputs: low-power lasers and high-power lasers. Low-power lasers typically produce up to 5 watts of power, while high-power lasers can produce up to and beyond 10,000 watts of power. Low-power lasers are most commonly used in medical, scientific, industrial and consumer applications. These lasers typically produce power outputs ranging from 0.1 to 5 watts. Common types of low-power lasers include diode lasers, gas lasers, and solid-state lasers such as Nd:YAG lasers.

High-power lasers are typically used for military and aerospace applications. These lasers typically produce power outputs of hundreds to thousands of watts. Common types of high-power lasers include CO2 lasers, excimer lasers, and free-electron lasers. In addition to these two main categories, there are also specialty lasers that produce unique power outputs. These lasers typically produce power outputs ranging from very low levels (e.g. femtowatts) to very high levels (e.g. megawatts). Common types of specialty lasers include ultrafast lasers, x-ray lasers, and ultra-intense lasers.

How to Calculate the Required Wattage of a Laser for Specific Applications

The wattage of a laser is an important factor when considering the proper laser for a specific application. It is important to understand that higher wattage lasers will create a more intense beam, and thus, will have greater capability when it comes to a given application. To properly calculate the wattage of the laser needed for a given application, it is important to consider the output parameters, such as beam intensity, beam diameter, beam divergence, and power density. The first step in calculating the wattage of the laser needed for a specific application is to determine the output parameters for the laser. Beam intensity, or irradiance, is the amount of power that is emitted from the laser in a given area. This is usually measured in watts per square centimeter (W/cm2).

The beam diameter is the distance across the beam and is typically measured in millimeters (mm). The beam divergence is the angle at which the beam expands from the source and is measured in milliradians (mrad). Finally, the power density of the laser is the amount of power that is emitted from the laser in a given area and is usually measured in watts per square millimeter (W/mm2). Once the output parameters are determined, the wattage of the laser can be calculated by multiplying these parameters together. To calculate the wattage of the laser, the beam intensity, beam diameter, beam divergence, and power density are each multiplied together. For example, if the beam intensity is 10 W/cm2, the beam diameter is 5 mm, the beam divergence is 5 mrad, and the power density is 5 W/mm2, then the wattage of the laser is equal to 10 x 5 x 5 x 5 = 1250 W.

In summary, when considering the wattage of a laser for a specific application, it is important to consider the output parameters of the laser. These parameters include beam intensity, beam diameter, beam divergence, and power density. Once these parameters are determined, the wattage of the laser can be calculated by multiplying them together. Knowing the wattage of the laser is important for ensuring the proper laser is chosen for any given application.

What Are the Advantages of High Wattage Lasers?

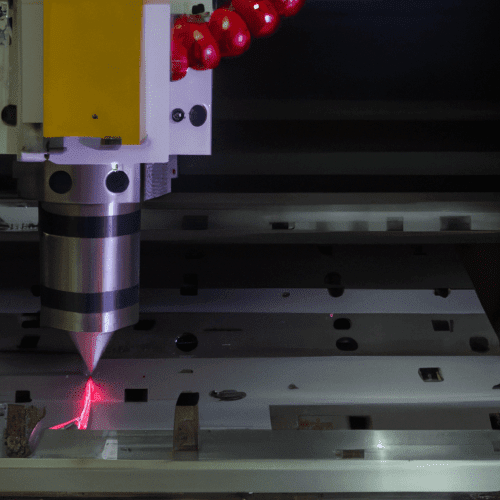

High wattage lasers offer several advantages in a variety of applications. The most significant benefit of high wattage lasers is their ability to generate higher power levels than lower wattage lasers, which can be used to achieve faster processing speeds and higher production capacities. Additionally, they are capable of producing more efficient results, as the higher power can produce precise cuts with less edge distortion. High wattage lasers also provide a higher level of accuracy and precision than lower wattage lasers, as the higher power level provides greater control over the cutting process.

With more power, the laser can cut more accurately and with a finer resolution, which can be beneficial in the production of intricate parts and components. Furthermore, high wattage lasers can be used to produce higher-quality cuts with a superior finish, as the higher power enables the laser to achieve better edge finish and improved surface finish. In addition, high wattage lasers can be used to produce deep cuts and cut through thicker materials with greater ease. This can be useful in applications such as machining, where the laser is used to cut through tougher materials such as metal or stone. The higher power can also be beneficial in laser welding, as it can produce deeper welds with fewer defects. Overall, high wattage lasers offer a range of advantages that can be beneficial in many different applications. By providing higher power levels and more accurate cuts, they can enable faster processing speeds, greater production capacities, and improved results.

How to Choose a Laser with the Optimal Wattage for Your Needs

Choosing the right laser with the optimal wattage for your needs is an essential step in finding the right tool for any job. The wattage of a laser is a measure of the power of the beam and determines the speed and accuracy of a laser’s performance. When selecting a laser, it is important to consider the desired outcome and the material being cut or engraved. The wattage of a laser can range from a few watts to hundreds of watts, and the type of laser you choose should be based on the type of work you plan to do. For example, if you plan to cut through thin materials such as paper or fabric, then a low-powered laser with around 10 watts would be sufficient. On the other hand, if you plan to cut through thicker materials such as wood or metal, then a higher-powered laser with over 100 watts would be required. In addition to the wattage of the laser, you should also consider the beam size. The beam size is important because it determines the accuracy of the cuts.

A larger beam will produce a wider cut, while a smaller beam produces more precise cuts. Finally, it is important to consider the type of laser you are purchasing. Different types of lasers are designed to be used for different types of applications. For example, if you are looking for a laser to mark metals, then a fiber laser would be the best option. On the other hand, if you are looking for a laser to engrave glass, then a CO2 laser would be the most suitable choice. By taking the time to consider the wattage, beam size, and type of laser you need for your project, you can ensure that you select the optimal laser for your needs. With the right choice, you will be able to achieve the best results and get the most out of your investment.

What Are the Different Wattage Ranges of Lasers and Their Applications?

Lasers are devices that create intense light beams that can be used for various applications. Lasers are distinguished by their wattage, which is a measurement of the energy output of the laser. Depending on the wattage, lasers can be used for a variety of purposes, from industrial processes to medical treatments. Low-power lasers, typically 1 to 5 watts, are often used for industrial processes such as cutting and welding. These lasers are usually pulsed, meaning that the laser will emit short bursts of energy to perform specific tasks. Low-power lasers are also used in laser printers, laser pointers, and laser engravers. Mid-power lasers, ranging from 5 to 50 watts, are used for a variety of medical applications. These lasers are used to treat conditions such as eye diseases, vascular issues, and skin lesions.

Mid-power lasers are also used for cosmetic treatments such as hair removal and tattoo removal. High-power lasers, ranging from 50 to 1,000 watts, are used for a variety of industrial and scientific applications. These lasers are used for welding and cutting metal, creating micro-scale components, and powering high-energy research experiments. High-power lasers are also used for military applications such as target designation and countermeasures. Ultra-high-power lasers, above 1,000 watts, are used primarily for scientific research. These lasers are capable of creating intense, high-energy pulses that can be used to study the effects of extreme conditions on matter. Ultra-high-power lasers are also used to simulate nuclear reactions and other high-energy processes.