Learning CNC machining is a challenging but achievable skill that requires dedication and time to master. While basic operations can be learned in a few hours through tutorials, becoming proficient typically takes several years of hands-on experience and continuous learning. CNC machining involves understanding both the mechanical aspects of the machines and the programming required to control them. Key areas to master include G-code programming, CAM software operation, tooling selection, material properties, and machine setup.

The learning curve can be steep, as it combines elements of engineering, computer science, and traditional machining. However, with persistence and practice, most individuals can become competent CNC operators within 1-2 years. Achieving true mastery, where one can efficiently program complex parts and troubleshoot advanced issues, often requires 3-5 years or more of consistent work in the field. Despite the challenges, many find CNC machining to be a rewarding career path with opportunities for growth and innovation in various manufacturing industries.

- Learning CNC machining requires understanding the mechanical functioning of the machines and proficiency in programming.

- Familiarity with CNC programming languages like G-code is essential.

- CNC machines come in various types, including milling and turning machines, as well as more complex multi-axis machines.

- Manual programming is a fundamental skill in CNC machining.

- Mastery of CNC machining can lead to rewarding career opportunities in industries such as automotive, aerospace, and manufacturing.

Understanding CNC Machining and its Applications

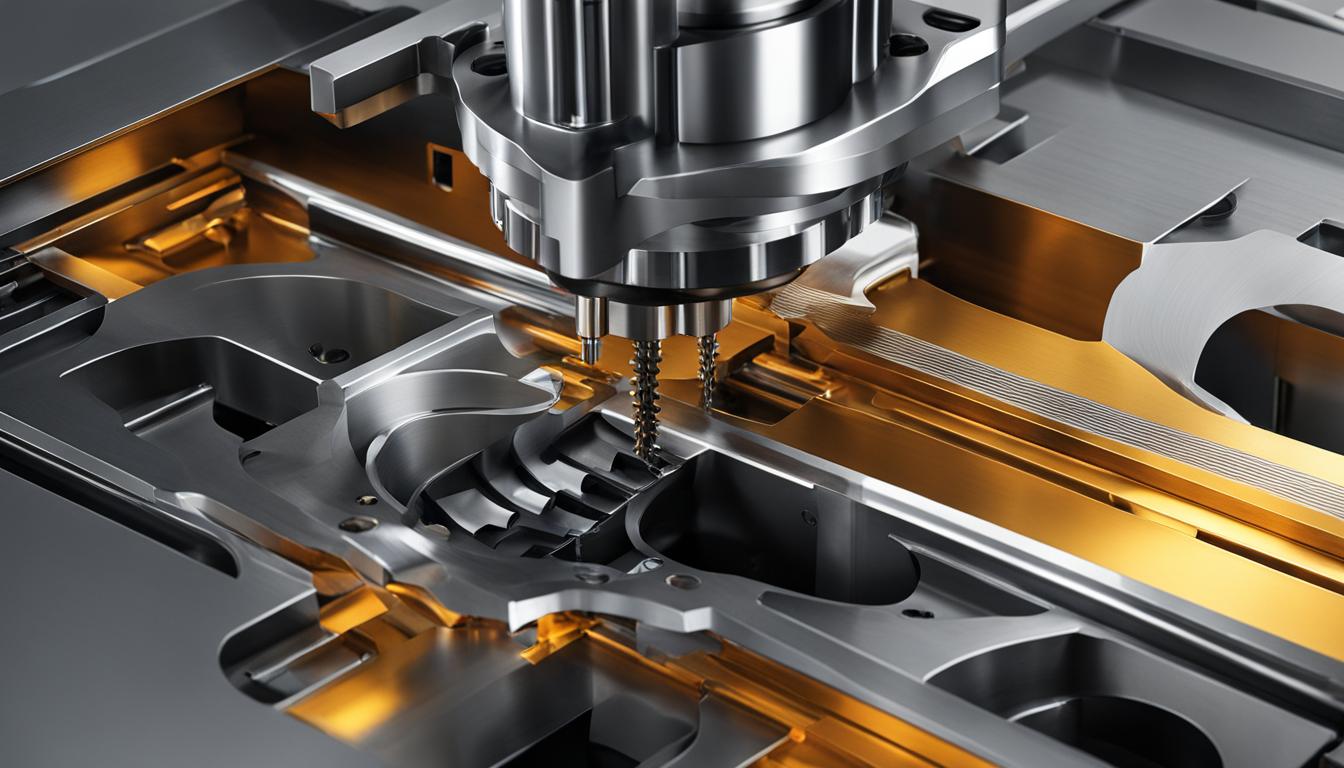

In the world of manufacturing, CNC machining stands as a versatile and precise method for creating complex parts with ease. By employing computer-controlled machines, CNC machining operates through a subtractive process, removing material from a workpiece to shape it into the desired form.

CNC machining can be applied to a wide range of materials, including wood, aluminum, and steel. Its ability to work with various materials makes it an indispensable tool in industries such as automotive, aerospace, and manufacturing. The precision and speed of CNC machines, with tolerances as low as ±0.001mm, enable the production of intricate and accurate components.

From crafting intricate engine parts for high-performance vehicles to fabricating aerodynamic components for aircraft, CNC machining plays a crucial role in today’s manufacturing processes. With its ability to produce complex shapes and achieve consistent quality, CNC machining offers unmatched flexibility and efficiency in the production of parts and components.

Take a look at the diagram below for a better understanding of the CNC machining process:

| CNC Machining Applications | Industries |

|---|---|

| Aerospace | Aviation, space exploration |

| Automotive | Vehicle manufacturing, racing |

| Manufacturing | General machinery, production |

| Engineering | Prototyping, product development |

Skills Required for CNC Machining

To excel in CNC machining, it is essential to have a strong foundation of skills that encompass both mechanical understanding and programming proficiency. Let’s explore the key areas of expertise required to become a successful CNC machinist:

Mechanical Understanding

A deep understanding of the mechanical functioning of CNC machines is crucial for effectively operating and troubleshooting them. Machinists should possess knowledge of:

- Machine calibration techniques to ensure accurate and precise machining

- Tooling selection and optimization for different materials and machining operations

- Feed speeds and cutting parameters to maximize productivity and achieve desired surface finishes

- Safe operation practices to ensure personal and equipment safety

Programming Proficiency

Machining programming is a fundamental skill for CNC machinists. Proficiency in programming empowers them to input instructions that govern the machine’s movements and actions. Key programming skills include:

- Familiarity with CNC programming languages, such as G-code, to create and modify programs

- Ability to interpret engineering drawings and translate them into CNC programs

- An understanding of programming concepts like tool paths, tool offsets, and work coordinate systems

While mastering these skills takes time and experience, there are numerous resources available for training and tutorials to help beginners get started. Many technical institutes, vocational schools, and online platforms offer CNC machining training programs that cover both theoretical knowledge and practical application. These programs provide hands-on experience with CNC machines and software, allowing aspiring machinists to develop their skills in a structured and guided manner.

With dedication and continuous learning, individuals can acquire the necessary CNC machining skills to embark on a successful career in this field.

Different Types of CNC Machines

CNC machines play a crucial role in modern manufacturing processes, providing precise and efficient solutions for various applications. Understanding the different types of CNC machines can help you choose the right one for your specific projects. Let’s explore the various types of CNC machines available:

CNC Milling Machines

CNC milling machines are versatile tools capable of removing material from a workpiece using rotary cutters. These machines are ideal for creating complex shapes and parts with high precision. CNC milling machines can be categorized into two main types:

- Vertical milling machines: These machines have a vertical spindle that moves the cutting tool up and down for vertical operations.

- Horizontal milling machines: These machines have a horizontal spindle and are suitable for larger workpieces or heavy-duty machining.

CNC Turning Machines

CNC turning machines, also known as lathes, are used to create cylindrical parts by rotating the workpiece against a cutting tool. These machines are commonly used for tasks such as drilling, grooving, and threading. CNC turning machines can be classified into:

- 2-axis turning machines: These machines perform operations on the X and Z axes, allowing for basic turning operations.

- Multi-axis turning machines: These machines have additional axes, such as the Y-axis and C-axis, enabling more complex and precise operations.

Multi-Axis CNC Machines

Multi-axis CNC machines, also referred to as multi-axis machining centers, offer even greater flexibility and versatility. These machines can perform operations on multiple axes simultaneously, resulting in enhanced efficiency and accuracy. Some common types of multi-axis CNC machines include:

| Machine Type | Number of Axes | Applications |

|---|---|---|

| 3-axis machines | 3 | General milling and turning operations |

| 4-axis machines | 4 | Rotary-axis machining, such as cylindrical engraving |

| 5-axis machines | 5 | Complex and intricate machining, aerospace industry |

| 6-axis machines | 6 | Simultaneous multi-axis milling and turning operations |

These multi-axis machines offer unparalleled capabilities, allowing for the production of intricate and precise parts that would be difficult or impossible to create using conventional CNC machines.

By understanding the different types of CNC machines, you can select the most suitable one for your specific manufacturing needs. Whether it’s CNC milling, CNC turning, or multi-axis machines, each type offers unique advantages that can significantly impact the efficiency and quality of your production process.

Manual Programming vs. CAM Programming

CNC programming is a crucial aspect of CNC machining, and there are different approaches to accomplish it. Two common methods are manual programming and CAM programming. Let’s explore the differences between these two approaches.

Manual Programming:

In manual programming, machinists write out the G-code instructions manually. This approach requires a strong understanding of the programming language and the machine’s capabilities. While it may take more time and expertise, manual programming offers greater control and flexibility in adjusting and troubleshooting programs directly at the machine. It also allows programmers to have a deeper understanding of the programming process, making it easier to optimize programs for efficiency.

CAM Programming:

CAM programming, on the other hand, involves using computer software to generate the required G-code automatically. With CAM software, programmers can create programs visually or by defining specific parameters. This approach reduces the manual effort required to write the code and can be more efficient for complex parts with intricate geometries. CAM programming also provides simulation capabilities, allowing programmers to visualize the machining process before physically executing it.

Both manual programming and CAM programming have their advantages and disadvantages. Manual programming offers a deeper understanding and control over the programming process, while CAM programming provides automation and time-saving benefits. It’s recommended for aspiring CNC programmers to have a good grasp of manual programming before transitioning to CAM programming to better understand the intricacies of CNC programming.

Stages of Difficulty for CNC Programming

CNC programming encompasses a wide range of complexity levels, from beginner to advanced. The difficulty of programming depends on the intricacy of the job at hand and the type of CNC machine being utilized. Let’s explore the various stages of difficulty involved in CNC programming.

1. Beginner CNC Programming

For those new to CNC programming, starting with basic 2-1/2 axis machining is a common entry point. This level of programming involves controlling the machine’s movement along the X, Y, and Z axes and is relatively straightforward to grasp. It focuses on simple geometries and does not require advanced programming techniques.

At this stage, manual programming and conversational programming methods can be employed. Manual programming involves writing out the CNC code line by line, while conversational programming uses a simplified interface to input commands and create programs. Both methods are suitable for beginners and allow for hands-on learning.

2. Intermediate CNC Programming

As CNC programming skills progress, the complexity of the jobs tackled increases. Intermediate CNC programming encompasses more advanced 3-axis machining, which introduces additional movement along one or more rotational axes, such as the A, B, or C axis.

In this stage, programmers may utilize Computer-Aided Manufacturing (CAM) software to generate G-code. CAM software makes it easier to handle complex geometries, automate repetitive tasks, and optimize tool paths. Intermediate programmers gain experience in optimizing cutting speeds, feed rates, and tool selection to achieve efficient and accurate machining.

3. Advanced CNC Programming

At the advanced level, CNC programming involves intricate 4-axis and 5-axis machining. These machines provide even greater flexibility and precision by enabling movement along additional rotational axes, allowing for complex geometric shapes and multi-sided machining.

To master advanced CNC programming, programmers must possess a deep understanding of machine kinematics, programming techniques specific to multi-axis machines, and advanced toolpath strategies. They may need to employ specialized CAM software tailored to the capabilities of the specific machine and workpiece.

As your programming skills develop, it’s essential to gradually progress through these stages and continuously learn more advanced techniques. Building a solid foundation in beginner CNC programming, acquiring proficiency in intermediate CNC programming, and eventually mastering advanced CNC programming will pave the way for successful and fulfilling CNC machining careers.

Importance of Manual Programming

Manual programming plays a crucial role in CNC machining. While Computer-Aided Manufacturing (CAM) programming is widely used and offers convenience, understanding manual programming is still essential for machinists. Learning the art of manual programming not only enhances your understanding of the programming process but also provides you with greater control and flexibility when troubleshooting or making on-the-fly changes at the machine.

By mastering manual programming, you gain a deep comprehension of the intricacies involved in CNC machining. It allows you to fine-tune every aspect of the program, optimizing tool paths, feed speeds, and machine operations to achieve the desired outcome. Manual programming empowers machinists to take full advantage of the machine’s capabilities and adapt to various production requirements efficiently.

Moreover, manual programming fosters self-reliance and adaptability. In a rapidly evolving manufacturing environment, knowing how to program manually equips machinists with the skills to handle unforeseen circumstances or unconventional machining scenarios. It enables them to make modifications swiftly, experiment with different approaches, and creatively solve problems.

While CAM programming delivers efficiency by automating the programming process, it’s important not to solely rely on it. As a machinist, manual programming enables you to bridge the gap between the machine and your expertise, unlocking endless possibilities and pushing the boundaries of CNC machining further.

So, whether you are a beginner or an experienced machinist, dedicating time to learn and master manual programming is indispensable. It empowers you to unleash your full creative potential, become a well-rounded CNC programmer, and elevate your machining skills to new heights.

| Advantages of Manual Programming | Benefits |

|---|---|

| Deeper understanding of programming process | 1. Enhanced troubleshooting capabilities |

| Greater control and flexibility | 2. Ability to make on-the-fly changes |

| Better optimization of tool paths and feed speeds | 3. Adaptability to unconventional machining scenarios |

| Improved self-reliance and experimental capabilities | 4. Creative problem-solving skills |

| Efficient adaptation to changing production requirements | 5. Unleashing full creative potential |

Conclusion and Career Outlook

Mastery of CNC machining requires time and experience, but it is a highly valuable skill sought after in numerous industries. With the continuous development of automation, CNC machining remains relevant and offers promising career opportunities. By dedicating yourself to learning and keeping up with advancements in the field, you can establish yourself as a skilled CNC machinist and embark on a successful and well-paid career in machining.

The demand for CNC machining professionals is driven by the need for precision manufacturing in industries such as automotive, aerospace, and electronics. As global industries continue to evolve, the reliance on CNC machining technology is expected to grow. Skilled machinists capable of operating and programming these complex machines will be essential to meet the demand for high-quality and intricate parts.

To pursue a career in CNC machining, you can start by enrolling in specialized training programs or apprenticeships offered by technical schools or manufacturing organizations. These programs provide hands-on experience and knowledge in operating CNC machines, reading technical drawings, and programming codes.

As you gain experience and expertise, you can advance your career by taking on more complex projects and specializing in specific industries or types of CNC machines. Continuous learning and staying updated with advancements in CNC technology and programming languages will also be crucial for career growth and remaining competitive in the industry.