The M3D Printer Guide offers a comprehensive exploration of 3D printing possibilities, catering to both novice and experienced users. This versatile device opens up a world of creative opportunities, allowing users to bring their digital designs to life in tangible form. With its user-friendly interface and compact design, the M3D printer is ideal for home use, educational settings, and small businesses. It supports a wide range of materials, including PLA, ABS, and specialty filaments, enabling the creation of diverse objects from decorative items to functional prototypes.

The guide delves into the printer’s features, such as its high-resolution capabilities, adjustable print settings, and compatibility with various 3D modeling software. It also provides valuable insights on optimizing print quality, troubleshooting common issues, and maintaining the printer for long-term use. By following this guide, users can unlock the full potential of their M3D printer, expanding their creative horizons and exploring the endless possibilities of 3D printing technology.

- Discover the versatility and affordability of the M3D printer.

- Explore the high-resolution printing capabilities of the M3D printer.

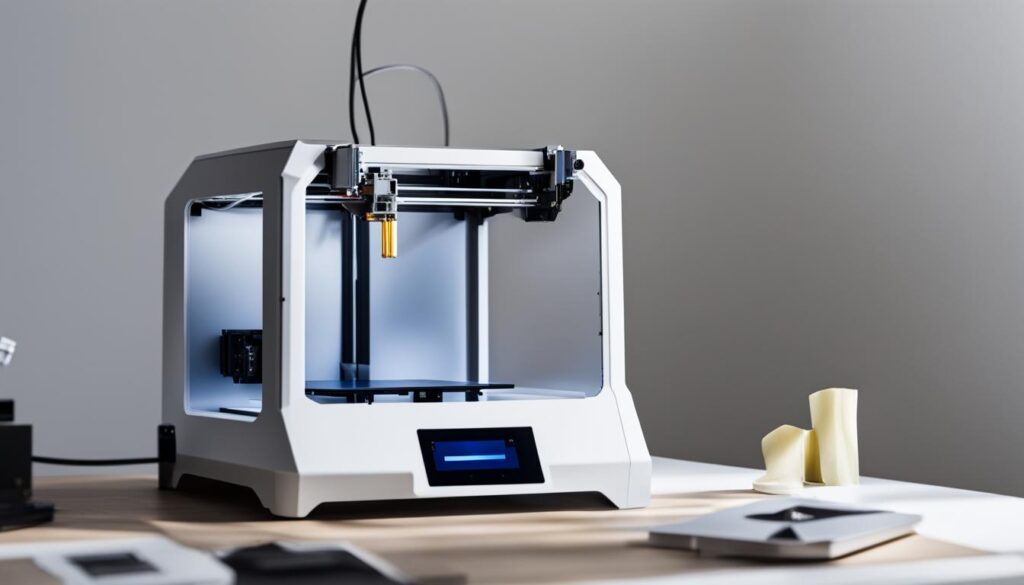

- Learn about the compact design and innovative technology of the M3D printer.

- Find valuable information on troubleshooting and replacement parts for the M3D printer.

- Access M3D printer reviews, troubleshooting resources, and replacement parts information.

The M3D Micro 3D Printer: A Quick Overview

The M3D Micro 3D printer is a revolutionary device that brings professional-grade 3D printing capabilities to consumers. With its compact design and high-resolution printing capabilities, this printer is perfect for both professionals and hobbyists alike. Let’s take a closer look at the specifications, features, and software of the M3D Micro.

Specifications

The M3D Micro offers an impressive build volume, with a lower build volume of 110 mm x 107 mm x 73.5 mm and an upper build volume of 80 mm x 68 mm x 38 mm. This allows you to print a wide range of objects in various sizes. The printer uses a nozzle diameter of 0.35 mm, ensuring precision and accuracy in every print. With a layer thickness of 0.05 mm, the M3D Micro delivers smooth and detailed prints.

Features

The M3D Micro is packed with features that make 3D printing a breeze. It supports various file types such as .STL and .OBJ, ensuring compatibility with a wide range of 3D modeling software. The printer is compatible with both Windows and Mac operating systems, making it accessible to a large user base. Additionally, the M3D Micro comes with M3D software, a user-friendly program that allows for seamless printing and customization of print settings.

Software

The M3D software is a key component of the M3D Micro 3D printer. It provides an intuitive interface that makes it easy to upload, modify, and print 3D models. The software allows you to adjust print settings such as resolution, infill density, and print speed, giving you control over the final print quality. With its user-friendly design and powerful features, the M3D software ensures a smooth and enjoyable printing experience.

Setting Up the M3D Micro 3D Printer

To set up the M3D Micro 3D printer, follow these simple steps:

- Start by unboxing the printer and removing all packaging materials.

- Make sure to remove the “Gantry Clips” located on the front left and front right corners of the printer.

- Connect the printer to your computer using the provided M3D USB cable.

- Insert the power supply into the round hole on the back of the printer.

- Plug the power supply into a wall socket to power on the printer.

The M3D Micro 3D printer is compatible with both Windows and Mac operating systems. It features a USB interface for easy connectivity.

By following these steps, you will have your M3D Micro 3D printer set up and ready to unleash your creativity.

Installing Filament on the M3D Micro 3D Printer

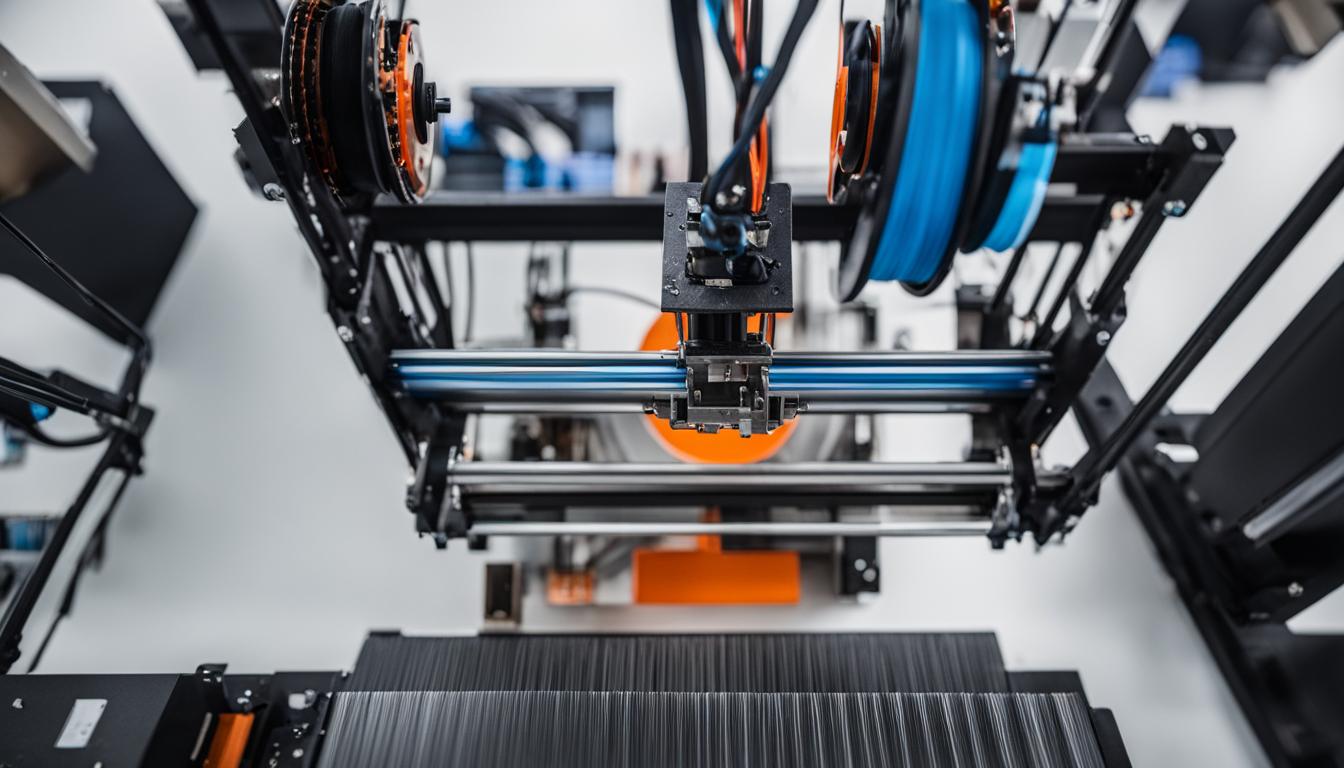

When it comes to filament installation on the M3D Micro 3D printer, users have the option to install it either internally or externally. Let’s explore both methods in detail:

Internal Filament Installation

With internal filament installation, the filament path starts underneath the print bed through the black filament tube. This method is suitable for users who prefer a cleaner aesthetic, as the filament is concealed within the printer.

External Filament Installation

For those who prioritize convenience and easy access, the M3D Micro also supports external filament installation. This method involves loading the filament via the external feed port, located at the top of the extruder head. It allows for quick and hassle-free filament changes, saving time during the printing process.

During the filament loading process, it is essential to ensure that the filament catches the extruder gear properly. This ensures smooth and continuous filament feeding, preventing any interruptions or filament jams that could affect the print quality.

The M3D Micro 3D printer is compatible with a wide range of filament types, including ABS, PLA, nylon, and professional-grade filaments. This versatility allows users to choose the most suitable filament for their specific printing needs, whether it’s for prototyping, artistic creations, or functional parts.

Now that we’ve covered the filament installation options and supported filament types, let’s move on to the next section to explore the process of printing with the M3D Micro 3D printer.

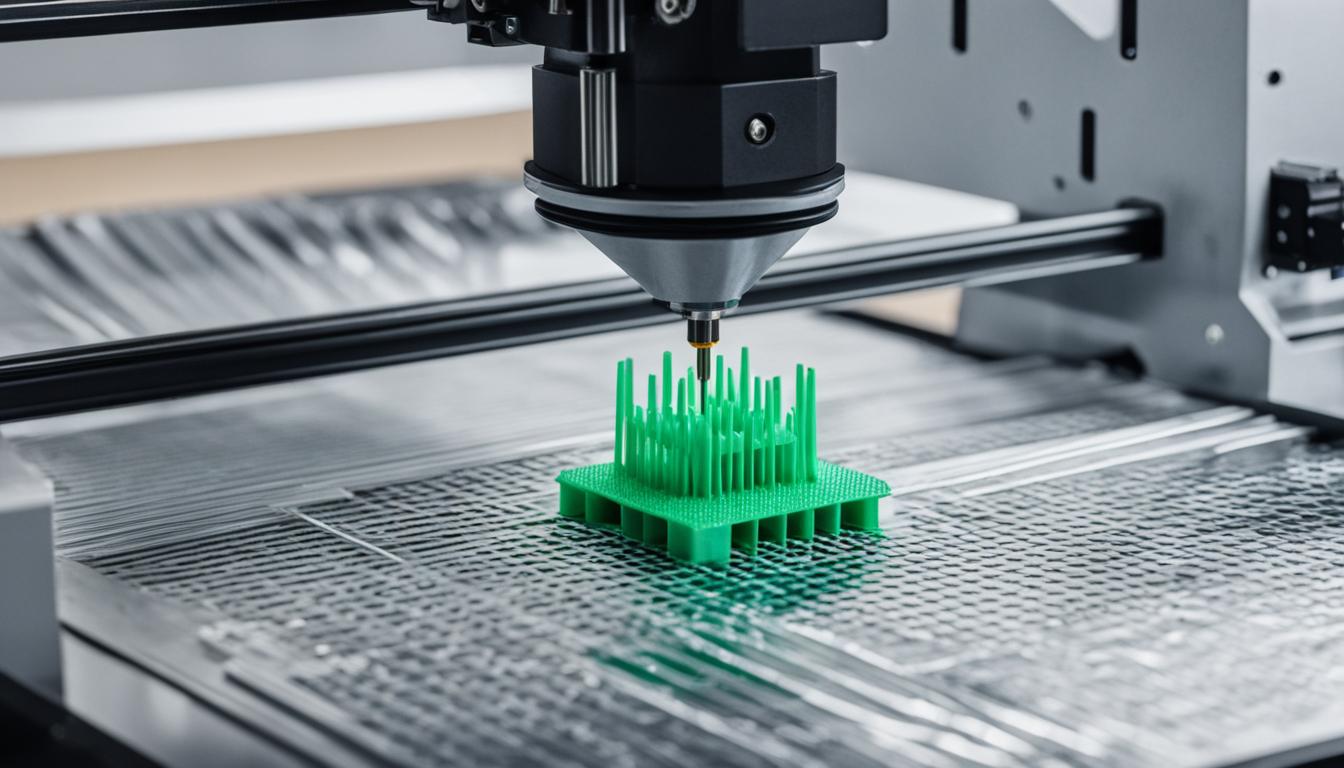

Printing with the M3D Micro 3D Printer

To start printing with the M3D Micro, it is recommended to perform a quick calibration to ensure a successful first print layer. This can be done through the printer settings in the M3D software. Once the printer is calibrated, load the desired model into the software and adjust the print settings according to your preferences.

The M3D Micro offers various print quality options, allowing you to choose the desired layer resolution and print speed. The print settings play a crucial role in determining the overall print quality and speed. Higher layer resolutions result in finer details but may increase the printing time, while lower resolutions may sacrifice some details but can be printed faster.

Additionally, the print speed setting determines how fast the printer moves while extruding filament. Adjusting the print speed can impact the overall print time. It’s important to find the right balance between speed and quality to achieve the desired results.

Below is a table illustrating the available print quality options and the corresponding print speed ranges for the M3D Micro 3D printer:

| Print Quality | Layer Resolution | Print Speed |

|---|---|---|

| Low | 0.20 mm | 10-30 mm/s |

| Medium | 0.15 mm | 30-50 mm/s |

| High | 0.10 mm | 50-70 mm/s |

Experiment with different print settings to find the optimal balance between print quality and speed based on your specific printing needs and requirements. Keep in mind that print quality and print speed can vary depending on the complexity and size of the model being printed.

Troubleshooting the M3D Micro 3D Printer

If you encounter any issues with your M3D Micro 3D printer, don’t worry! There are several troubleshooting solutions available to help you get back to printing with ease. To resolve common printing problems, visit the M3D support page, where you’ll find technical articles, videos, and documentation that provide step-by-step guidance. Whether you’re experiencing difficulties with print quality, connectivity, or software, the support page is a valuable resource for troubleshooting your M3D printer.

If you can’t find the solution you’re looking for or need additional assistance, consider reaching out to the M3D customer support team. They are dedicated to providing prompt and helpful support to ensure your printing experience is smooth and enjoyable. Whether you have questions about setup, software, or any other aspect of your printer, the customer support team is there to help.

Frequently Asked Questions (FAQ)

For quick answers to common concerns, the M3D website offers an extensive FAQ section. This resource addresses frequently asked questions related to M3D printer troubleshooting, maintenance, and general usage. Browse through the FAQ section to find answers to questions about print quality, filament installation, software compatibility, and more. These frequently asked questions provide valuable insights and solutions, saving you time and effort in resolving any printer issues you may encounter.

| Common Printer Issues | Possible Solutions |

|---|---|

| The printer is not powering on. | Check the power supply connection and ensure it is plugged in properly. If the issue persists, contact customer support for further assistance. |

| Poor print quality or incomplete prints. | Ensure the print bed is leveled correctly and that the filament is loaded properly. Check the print settings for any adjustments that may improve print quality. |

| Printer connectivity issues. | Check the USB cable connection between the printer and your computer. Additionally, verify that you have the latest version of the M3D software installed. |

| Error messages or software crashes. | Restart the M3D software and ensure your computer meets the minimum system requirements. If the problem persists, uninstall and reinstall the software. |

Understanding Print Settings on the M3D Micro 3D Printer

When using the M3D Micro 3D printer, understanding the print settings is crucial for achieving the desired print quality and characteristics. This section will explain the important print settings that users should be familiar with.

Print Quality

Print quality refers to the layer height of the printed models. It determines the level of detail and precision in the final prints. The M3D Micro offers adjustable layer heights ranging from 0.05mm to 0.35mm. Higher quality prints have smaller layer heights, resulting in smoother and more accurate models. However, it’s important to note that prints with smaller layer heights may take longer to complete.

Fill Density

Fill density determines the amount of filament printed inside the model. It affects the strength and density of the printed object. The M3D Micro allows users to adjust the fill density from 0% to 100%. Higher density prints have more filament inside the model, making them stronger but also requiring more filament. On the other hand, lower density prints use less filament and may have a more hollow structure. The choice of fill density depends on the intended use and desired characteristics of the printed object.

Bed Location

The bed location setting is vital for successful printing. It ensures that the print bed is properly positioned relative to the nozzle tip. Incorrect bed location can result in adhesion issues, warping, and improper layer adhesion. The M3D Micro allows users to adjust the bed location manually or use the auto-leveling feature for precise alignment.

| Setting | Description |

|---|---|

| Print Quality | Adjustable layer heights ranging from 0.05mm to 0.35mm |

| Fill Density | Adjustable from 0% to 100% to control the amount of filament printed inside the model |

| Bed Location | Manual adjustment or auto-leveling feature to ensure proper alignment between the print bed and nozzle tip |

By understanding and properly configuring these print settings on the M3D Micro 3D printer, users can optimize print quality, strength, and overall performance for their specific printing needs.

Safety Considerations for the M3D Micro 3D Printer

When using the M3D Micro 3D printer, it is important to prioritize safety to ensure a smooth printing experience. The printer reaches high temperatures during operation, with the nozzle tip and black insulator reaching over 200 degrees Celsius. To prevent burns, users should avoid touching these hot areas.

Additionally, it is crucial to keep hands away from moving parts while the printer is in operation. This helps minimize the risk of injury and ensures that the printing process proceeds unhindered.

To enhance safety, here are some key precautions to take when using the M3D Micro 3D printer:

- Avoid touching the nozzle tip and black insulator during operation to prevent burns.

- Keep hands away from moving parts to minimize the risk of injury.

- Do not leave the printer unattended while it is in use.

- Ensure a well-ventilated environment to dissipate any fumes that may be emitted during printing.

- Regularly inspect the printer for any signs of damage or wear and tear, and address issues promptly.

By following these safety precautions, users can enjoy a safe and worry-free printing experience with the M3D Micro 3D printer.

M3D Micro 3D Printer Safety Precautions

| Precaution | Description |

|---|---|

| Avoid touching hot components | Prevent burns by refraining from touching the nozzle tip and black insulator, which reach temperatures over 200 degrees Celsius. |

| Keep hands away from moving parts | Minimize the risk of injury by refraining from touching any moving parts of the printer during operation. |

| Do not leave the printer unattended | Always monitor the printer while it is in use to ensure safe and proper operation. |

| Ensure proper ventilation | Operate the printer in a well-ventilated environment to dissipate any fumes that may be emitted during the printing process. |

| Regularly inspect the printer | Check for any signs of damage or wear and tear on the printer, and address issues promptly to maintain safety and functionality. |

Warranty and Support for the M3D Micro 3D Printer

The M3D Micro 3D printer comes with a warranty that ensures peace of mind for users. The standard edition of the printer offers a 3-month warranty, while the retail edition extends the warranty period to 1 year. This warranty covers any manufacturing defects or malfunctions that may occur during normal use of the printer.

For any warranty claims or technical support, M3D provides excellent customer support services. Users can reach out to the M3D customer support team through their website or contact them via email or phone. The knowledgeable and friendly support staff is always ready to assist users with their queries, troubleshooting, and warranty claims.

In addition to customer support, M3D also offers a wide range of documentation to help users get the most out of their M3D Micro 3D printer. The M3D website provides comprehensive user manuals and troubleshooting guides that cover various aspects of the printer’s operation, maintenance, and troubleshooting. These resources are designed to empower users with the knowledge and information they need to successfully navigate any challenges they might encounter while using the M3D Micro.

For quick access to the M3D printer documentation, here is a list of the available resources:

- User Manual

- Quick Start Guide

- Troubleshooting Guide

- FAQs

With the warranty coverage and extensive support resources from M3D, users can confidently explore the possibilities of 3D printing with their M3D Micro 3D printer.

| Warranty | Standard Edition | Retail Edition |

|---|---|---|

| Duration | 3 months | 1 year |

| Coverage | Manufacturing defects and malfunctions | Manufacturing defects and malfunctions |

Where to Buy Replacement Parts for the M3D Micro 3D Printer

In the event that replacement parts are needed for the M3D Micro 3D printer, there are convenient options available for purchasing them. Users can acquire genuine replacement parts from authorized retailers or directly from M3D, ensuring optimal performance and compatibility.

Replacement parts for the M3D Micro 3D printer may include essential components such as print beds, nozzles, and other accessories. These parts are designed to seamlessly integrate with the printer and maintain its reliable functionality.

By purchasing from authorized retailers or directly from M3D, users can have peace of mind knowing that the replacement parts are authentic and specifically tailored for their M3D Micro 3D printer. This helps to prolong the lifespan of the printer and ensure consistent printing quality.

Whether it’s a print bed that needs replacing or a spare nozzle for backup, acquiring genuine M3D replacement parts is the best way to keep the M3D Micro 3D printer in optimal condition for all your 3D printing needs.

Conclusion

The M3D printer is not just an ordinary 3D printer; it is a gateway to endless possibilities in the world of 3D printing. With its compact design and high-resolution printing capabilities, the M3D printer offers a versatile and user-friendly solution for both professionals and hobbyists.

By investing in the M3D printer, users can unleash their creativity and bring their ideas to life. The printer’s innovative technology and advanced features allow for precise and detailed prints. Whether you are a professional searching for a reliable and professional-grade 3D printer or a hobbyist in need of an affordable option, the M3D printer exceeds expectations.

To fully maximize the potential of the M3D printer, it is crucial to ensure proper setup, regular maintenance, and troubleshooting when needed. By following the recommended guidelines and utilizing the available resources, users can overcome any challenges and achieve outstanding results.

In conclusion, the M3D printer is a top choice for those looking to explore the world of 3D printing. Its compact design, high-resolution printing capabilities, and user-friendly software make it an ideal option for both professionals and hobbyists. With its exceptional performance and versatility, the M3D printer opens up a world of endless possibilities in the realm of 3D printing.