Creality offers a wide range of 3D printers and accessories to enhance your printing experience. Their popular Ender series, including the Ender 3, Ender 3 V2, and Ender 5, provides affordable options for beginners and enthusiasts alike. For more advanced users, the CR series offers larger build volumes and additional features. Essential accessories include the Creality Sonic Pad, which speeds up printing while maintaining quality, and the Sprite Extruder Pro Kit, which improves feeding control and allows for high-temperature printing up to 300°C.

Other valuable upgrades are the CR-Touch Auto Leveling Sensor Kit for precise bed leveling, and the Dual Screw Rod Upgrade Kit for increased stability and precision. Creality also offers enclosures to improve print quality by maintaining a stable environment, and various mainboard upgrades like the Silent Mainboard V4.2.7 for quieter operation. For those looking to expand their capabilities, the CV-LaserModule enables engraving and cutting functionality. Creality’s extensive range of accessories, from nozzles and hotends to build plates and tool kits, allows users to customize and optimize their 3D printing setup for improved performance and versatility.

- Creality is a trusted brand in the 3D printing industry, known for its high-quality printers and user-friendly interfaces.

- This guide will cover key features, recommended models, and tips for choosing the right Creality 3D printer for your needs.

- Creality offers a variety of accessories that can enhance the performance and capabilities of their printers.

- Understanding 3D printing filaments and the essential parts of 3D printers is crucial for successful 3D printing.

- Creality printers come with advantages such as reliability, ease of use, and large build volumes.

Why Choose Creality 3D Printers

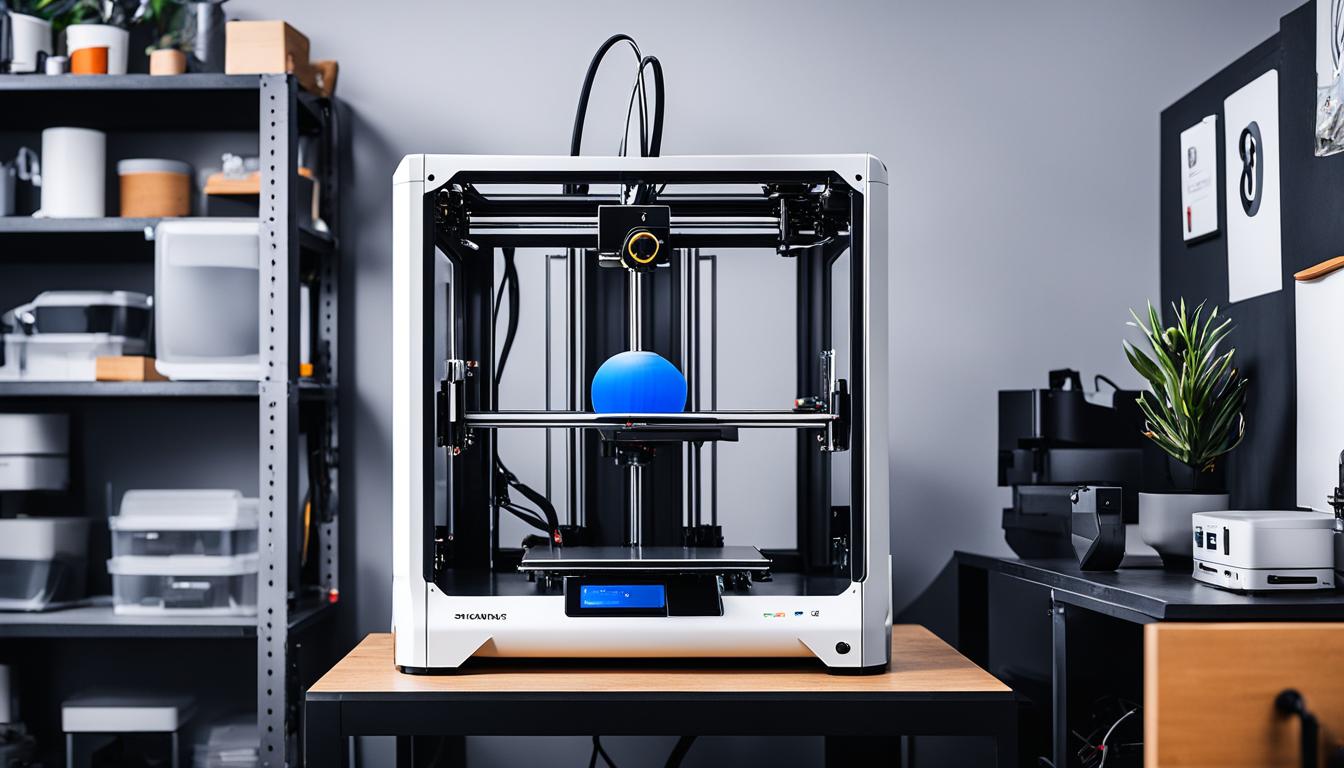

When it comes to 3D printing, Creality is a brand that stands out for its exceptional quality, reliability, and affordability. With over a decade of experience in the industry, Creality has become a trusted name among 3D printing enthusiasts and professionals. Whether you are a beginner or an experienced user, Creality 3D printers offer a range of benefits that set them apart from the competition.

Here are some key reasons why you should choose Creality:

- Quality: Creality is known for producing high-quality printers that consistently deliver outstanding results. Their printers are built with precision and attention to detail, ensuring that every print is of the highest standard.

- Reliability: Creality printers are renowned for their reliability. With durable components and robust construction, these printers can handle long hours of printing without compromising on performance.

- Affordability: One of the most appealing aspects of Creality 3D printers is their affordability. Despite their exceptional quality, Creality printers are priced competitively, making them accessible to a wide range of users.

By choosing a Creality 3D printer, you can have confidence in the print quality, dependability, and cost-effectiveness of your investment. Whether you are creating prototypes, functional parts, or artistic designs, a Creality printer will empower you to bring your ideas to life.

Creality 3D Printer Models

Creality offers a diverse range of 3D printer models to cater to different needs and preferences. Let’s take a closer look at some popular Creality printer models:

| Model | Key Features | Price Range |

|---|---|---|

| Ender 3 V2 | Easy assembly, large build volume, silent motherboard | $200 – $300 |

| Ender 5 Pro | Cube frame design, stable and precise printing | $300 – $400 |

| CR-10S Pro V2 | Auto bed leveling, dual-gear extruder | $500 – $600 |

These are just a few examples of the excellent Creality 3D printer models available. Each model offers unique features and advantages, allowing you to find the perfect printer for your specific requirements and budget.

Whether you are a hobbyist, educator, or professional, Creality 3D printers are an excellent choice. With their unbeatable combination of quality, reliability, and affordability, Creality printers are sure to impress and inspire your 3D printing journey.

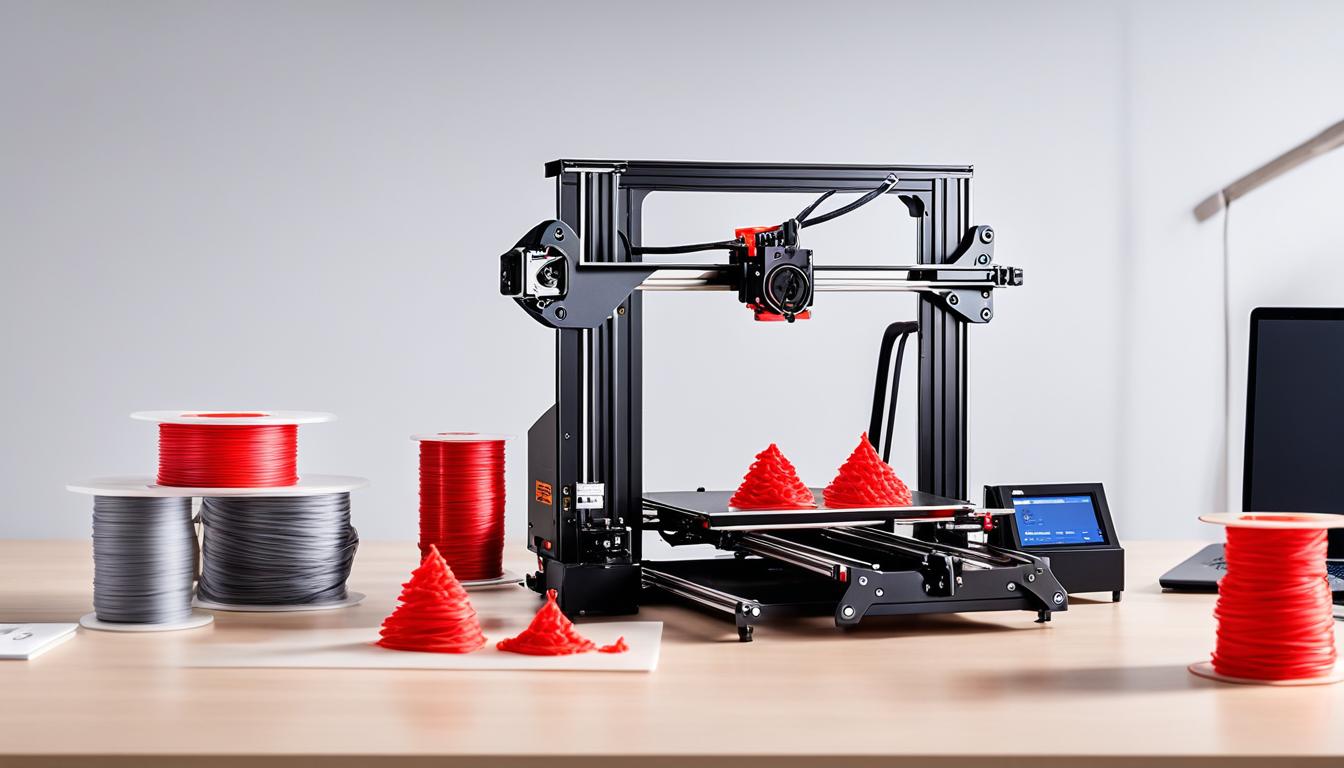

Understanding 3D Printing Filaments

When it comes to 3D printing, choosing the right filament is crucial for achieving desired results. Creality offers a wide range of high-quality 3D printing filaments, each with its own unique properties and applications. Let’s take a closer look at some of the most popular filaments available:

1. PLA (Polylactic Acid)

PLA is one of the most commonly used filaments in 3D printing. It is derived from renewable resources, such as cornstarch or sugarcane, making it biodegradable and environmentally friendly. PLA is known for its ease of printing and low warping tendencies, making it a great choice for beginners. It is available in a wide range of vibrant colors and is suitable for a variety of applications, including prototypes, figurines, and household items.

2. PETG (Polyethylene Terephthalate Glycol)

PETG is a durable and versatile filament that combines the advantages of both PLA and ABS. It offers excellent strength, flexibility, and impact resistance, making it suitable for functional parts and prototypes. PETG is also known for its chemical resistance and low shrinkage, resulting in minimal warping during the printing process. It is available in transparent and opaque colors, providing a wide array of options for different projects.

3. TPU (Thermoplastic Polyurethane)

TPU is a highly flexible filament that can be stretched, bent, and compressed without breaking. It is commonly used for creating parts that require elasticity, such as phone cases, footwear, and gaskets. TPU offers excellent layer adhesion and is resistant to abrasion, oil, and chemicals. Its unique properties make it ideal for both regular and industrial model printing.

4. ABS (Acrylonitrile Butadiene Styrene)

ABS is a durable and temperature-resistant filament widely used in commercial applications. It offers superior strength, impact resistance, and heat resistance compared to PLA and PETG. ABS is commonly used to create functional prototypes, automotive parts, and electronic enclosures. It requires a heated print bed and an enclosed printing environment to prevent warping.

5. Resin

For resin-based 3D printing, Creality offers a range of options to suit different needs. Standard resin is commonly used for high-resolution prints with smooth surface finishes. Water washable resin allows for easy post-processing by rinsing the printed object in water. PLA-based resin offers biodegradability and environmental friendliness similar to PLA filaments. Dental resin is specifically designed for dental applications, providing high accuracy and biocompatibility.

Understanding the characteristics and applications of these 3D printing filaments can help you select the right material for your specific project. Experimenting with different filaments allows for endless possibilities in creating functional prototypes, artistic models, and unique designs.

| Filament | Main Features | Applications |

|---|---|---|

| PLA | Biodegradable, easy to print, low warping | Prototypes, figurines, household items |

| PETG | Strength, flexibility, chemical resistance | Functional parts, prototypes |

| TPU | Flexibility, elasticity, abrasion resistance | Phone cases, footwear, gaskets |

| ABS | Durability, heat resistance, impact resistance | Functional prototypes, automotive parts |

| Resin | High resolution, smooth surface finish | Various applications based on resin type |

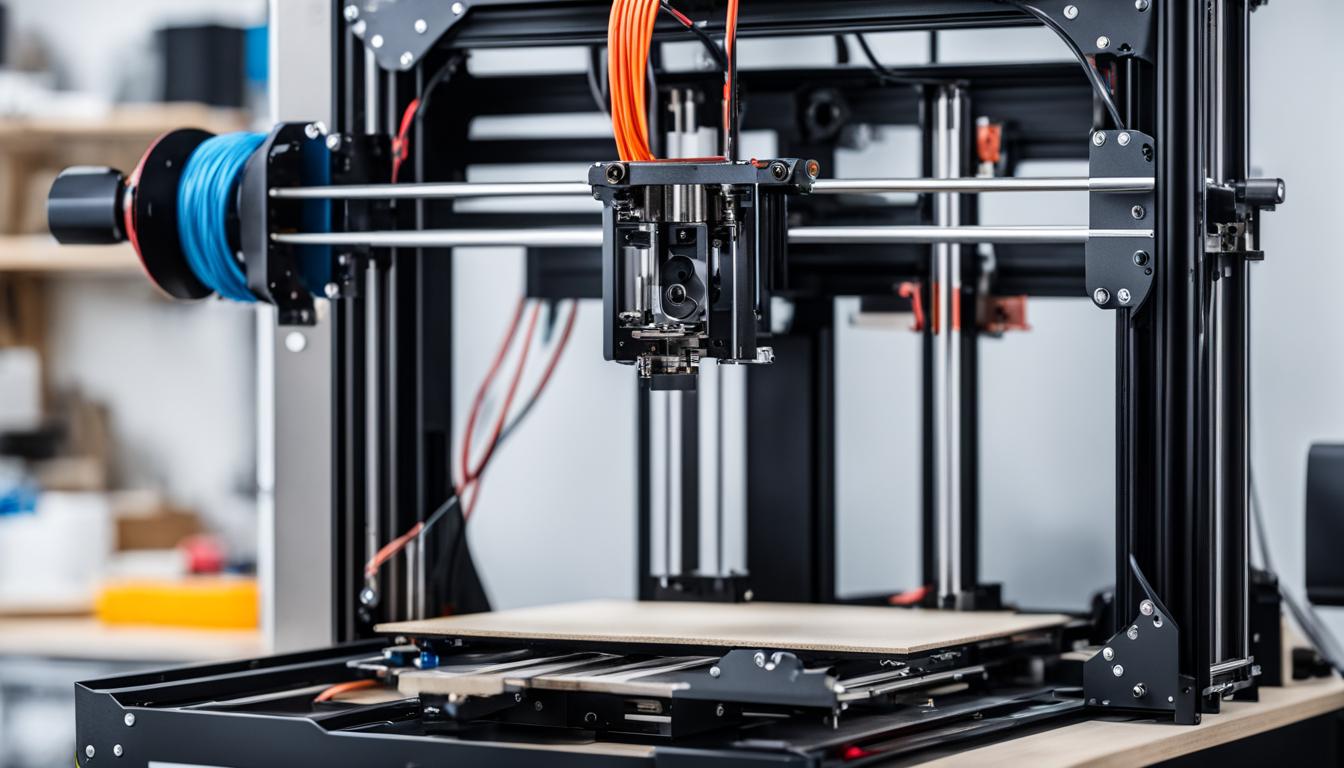

Essential Parts and Terminology of 3D Printers

To understand 3D printing, it’s important to familiarize yourself with the various parts and terminology of 3D printers. Each component plays a crucial role in the printing process, and knowing their functions will help you troubleshoot and upgrade your printer.

Hotend Assembly

The hotend assembly, also known as the extruder assembly, is responsible for melting the filament and depositing it onto the build plate. It consists of a heater block, a nozzle, a heat sink, and a fan. The heater block heats the filament to its melting point, while the nozzle determines the size and shape of the extruded filament. The heat sink and fan help dissipate heat and prevent the hotend from overheating.

Extruder

The extruder is the part of the printer that feeds the filament into the hotend assembly. It consists of a stepper motor, a drive gear, and a filament guide. The stepper motor moves the filament through the extruder, while the drive gear grips and pushes the filament forward. The filament guide ensures smooth and consistent filament feeding.

Heated Bed

The heated bed is a platform that provides heat to the build plate. It helps prevent warping and keeps the printed object firmly attached to the platform during the printing process. The heated bed is typically made of a heat-conductive material, such as aluminum, and is controlled by a thermostat to maintain a specific temperature.

Axes

3D printers operate along three axes: X, Y, and Z. The X-axis refers to the horizontal movement of the print head, the Y-axis represents the movement of the print bed, and the Z-axis controls the vertical movement of the print head and bed. These axes work together to define the dimensions and shape of the printed object.

Understanding these essential parts and terminology of 3D printers will empower you to optimize your printing process, troubleshoot issues effectively, and explore possibilities for printer upgrades.

Types of 3D Printing Technologies

When it comes to 3D printing, there are two primary technologies that dominate the industry: Fused Deposition Modeling (FDM) and Ultraviolet Photocuring (UV Photocuring). Each technology offers unique capabilities and advantages, catering to different printing needs and preferences.

Fused Deposition Modeling (FDM)

FDM printing, also known as Fused Filament Fabrication, is a widely adopted 3D printing technology. FDM printers use thermoplastic filament, typically in the form of a spool, that is heated and extruded through a nozzle. The molten plastic is then deposited layer by layer to gradually build the desired object.

FDM printers are known for their affordability and versatility. They can produce functional prototypes, hobbyist models, and even end-use parts with good durability. Some popular FDM printers include the Creality Ender 3 and the Prusa i3 MK3.

Ultraviolet Photocuring (UV Photocuring)

In contrast, UV photocuring technology uses a liquid resin that hardens when exposed to ultraviolet light. UV printers utilize a UV light source, such as an array of LEDs or a laser, to selectively cure the resin, solidifying it layer by layer to create the final object.

UV printers excel in producing highly detailed and intricate parts with smooth surfaces and fine features. They are commonly used in industries such as dentistry, jewelry, and prototyping small-scale models. The Formlabs Form 3 and the Anycubic Photon Mono X are popular options for UV printing.

To summarize:

| FDM Printing | UV Photocuring |

|---|---|

| Uses thermoplastic filament | Uses liquid resin |

| Affordable and versatile | Produces highly detailed parts |

| Good for functional prototypes and hobbyist models | Commonly used in dentistry, jewelry, and small-scale prototyping |

Both FDM and UV printing technologies have their strengths and are chosen based on specific project requirements. Whether you prioritize affordability and versatility or high-detail precision, there is a 3D printing technology that suits your needs.

Choosing the Right Creality 3D Printer

When it comes to selecting the perfect Creality 3D printer, you have a range of options to choose from. Whether you’re a beginner on a budget or a seasoned enthusiast looking for premium features, Creality has a printer that suits your needs. Let’s explore three popular models: Ender 3 V3 SE, Ender 3 Neo, and Creality K1.

Ender 3 V3 SE

The Ender 3 V3 SE is an excellent choice for those seeking affordability without compromising on performance. This printer comes equipped with an upgraded direct drive extruder, providing superior filament control and consistent prints. With its sturdy construction and reliable performance, the Ender 3 V3 SE is a cost-effective option for both beginners and experienced users.

Ender 3 Neo

If you’re looking for great value and added convenience, consider the Ender 3 Neo. This model comes with features such as auto bed leveling and a metal extruder, making it easy to achieve optimal print quality without the need for manual adjustments. With its user-friendly interface and reliable performance, the Ender 3 Neo is a popular choice among hobbyists and enthusiasts.

Creality K1

For those seeking a premium 3D printing experience, the Creality K1 offers advanced features and capabilities. With a larger build volume, faster print speeds, and enhanced control features, the Creality K1 is ideal for complex and high-resolution prints. Whether you’re a professional or an avid maker, the Creality K1 provides the tools you need to bring your creations to life.

In the table below, we compare the key specifications of these three Creality 3D printers:

| Model | Build Volume | Features | Price Range |

|---|---|---|---|

| Ender 3 V3 SE | 220mm x 220mm x 250mm | Direct drive extruder | $ |

| Ender 3 Neo | 220mm x 220mm x 250mm | Auto bed leveling, metal extruder | $$ |

| Creality K1 | 300mm x 300mm x 400mm | Larger build volume, faster print speeds, advanced control features | $$$ |

Now that you’re familiar with the Ender 3 V3 SE, Ender 3 Neo, and Creality K1, you can make an informed decision based on your printing needs, budget, and desired features. Whichever model you choose, rest assured that Creality printers offer reliability, quality, and a rewarding 3D printing experience.

Advantages of Creality 3D Printers

Creality 3D printers offer a range of advantages that make them a top choice for both beginners and experienced users. With a focus on reliability, ease of use, and large build volume, Creality printers provide a seamless 3D printing experience.

Reliability

Creality is renowned for producing printers that are highly reliable, minimizing the risk of print failures and downtime. Their printers undergo rigorous testing and quality control measures to ensure consistent and accurate prints.

Ease of Use

One of the standout features of Creality 3D printers is their user-friendly interface and intuitive operation. They require minimal calibration and setup time, allowing users to quickly start printing without the hassle of complex configurations.

Large Build Volume

Creality understands the importance of having a generous build volume for printing larger objects or multiple smaller objects in a single print. Their printers come in a variety of sizes, ensuring that there is a suitable option for every project.

| Advantages | Description |

|---|---|

| Reliability | Creality printers are known for their dependable performance, reducing the risk of print failures and wasted materials. |

| Ease of Use | With their user-friendly interfaces, Creality printers are easy to operate, making them suitable for beginners. |

| Large Build Volume | Creality offers printers with spacious build volumes, allowing for the creation of bigger and more intricate prints. |

Tips for Getting Started with Creality 3D Printers

When you first venture into the world of Creality 3D printers, it’s important to have a solid foundation to ensure successful prints. Here are some essential tips to help you get started, from calibration to maintenance:

1. Calibrate Your Printer

Calibration is a crucial step to ensure accurate and consistent prints. Begin by leveling the bed, adjusting the bed height at each corner to achieve a uniform distance between the nozzle and bed. This will prevent uneven prints and adhesion issues.

Next, calibrate the extruder steps to ensure accurate filament feeding. By measuring the amount of filament that’s actually extruded compared to what’s commanded, you can make necessary adjustments to achieve precise prints.

2. Choose the Right Print Settings

The success of your prints relies on selecting the appropriate print settings. Factors such as layer height, print speed, and temperature can greatly impact print quality. Experiment with different settings to find the optimal balance between speed and quality for your specific project.

3. Perform Regular Maintenance

To keep your Creality 3D printer running smoothly, regular maintenance is essential. Clean the nozzle regularly to prevent clogs and ensure consistent extrusion. You can use a nozzle cleaning tool or a small wire brush to remove any debris or filament buildup.

Additionally, clean the bed surface to maintain a strong adhesion between the print and bed. Use isopropyl alcohol or a mild detergent to gently wipe the bed surface to remove any oils or residue.

4. Stock Up on Filament

Having a well-stocked supply of filament is important for uninterrupted printing. Creality 3D printers support various filament types, such as PLA, ABS, PETG, and more. Each filament material has its own unique properties, so it’s essential to understand their characteristics and choose the appropriate filament for your project.

5. Understand Different Filament Types

To make informed decisions about filament selection, it’s crucial to understand the different types available. Here’s a brief overview of some commonly used filaments:

| Filament Type | Properties |

|---|---|

| PLA (Polylactic Acid) | Easy to print, biodegradable, wide range of colors |

| PETG (Polyethylene Terephthalate Glycol) | Strong, durable, temperature-resistant |

| ABS (Acrylonitrile Butadiene Styrene) | Durable, temperature-resistant, suitable for functional parts |

| TPU (Thermoplastic Polyurethane) | Flexible, elastic, ideal for wearables and functional prototypes |

| Resin | Used in UV Photocuring printers, offers high detail and smooth finish |

By familiarizing yourself with these filament types, you can select the appropriate material for your specific printing needs.

With these tips in mind, you’ll be well-equipped to embark on your 3D printing journey with your Creality printer. Remember, practice makes perfect, so don’t be afraid to experiment and learn along the way.

Expansion and Upgrades for Creality 3D Printers

Creality printers offer numerous expansion and upgrade options to enhance their capabilities. Whether you’re looking to add more color to your prints, increase the range of printable materials, or improve overall performance, there are plenty of options available.

Dual Extruders for Multi-Color Prints

One popular upgrade for Creality printers is the addition of dual extruders. With dual extruders, you can print objects using multiple colors or even different materials. This opens up a whole new world of possibilities for creating vibrant and intricate prints.

Hotend Upgrades for Higher Temperature Materials

If you’re interested in printing with high-temperature materials like nylon or polycarbonate, upgrading the hotend is a must. A high-quality hotend capable of reaching higher temperatures ensures better print consistency and allows you to experiment with a wider range of materials.

Enclosures for Better Temperature Control

To achieve optimal print quality, temperature control is crucial. Installing an enclosure around your Creality printer helps maintain a stable and controlled environment, minimizing the impact of external factors like drafts and temperature fluctuations. This is especially important when printing materials that are sensitive to temperature changes.

BLTouch for Auto Bed Leveling

Manual bed leveling can be time-consuming and tricky to get just right. That’s where the BLTouch comes in. By adding this auto bed leveling sensor to your Creality printer, you can eliminate the need for manual adjustments. The sensor measures the distance between the nozzle and the bed, ensuring a perfectly level printing surface with every print.

Accessories for Improved Print Quality and Performance

In addition to expansion and upgrades, various accessories can further enhance your Creality 3D printing experience. Consider investing in a filament dry box to keep your filament dry and prevent moisture-related issues during printing. Upgraded build surfaces, such as glass or specialized adhesive sheets, can improve adhesion and result in better print quality.

By exploring these expansion and upgrade options, you can take your Creality 3D printer to the next level. Whether you’re aiming for more versatility, enhanced performance, or improved print quality, there’s a wide range of options to suit your needs.

Troubleshooting Common Issues with Creality 3D Printers

While Creality 3D printers are known for their quality and reliability, like any 3D printer, they may encounter common issues that can affect print quality. It’s important to understand these issues and how to troubleshoot them effectively to ensure optimal performance. Here are some common issues you may encounter when using Creality 3D printers, along with their solutions:

Filament Clogs

One common issue that can occur is filament clogs, where the filament gets stuck and prevents proper extrusion. This can result in incomplete prints or uneven layers. To troubleshoot filament clogs:

- Check the filament path and make sure it is free from any obstructions.

- Ensure that the nozzle is clean and free from debris.

- Adjust the printing temperature to ensure proper melting of the filament.

- Use a higher-quality filament that is less prone to clogging.

Warping

Warping occurs when the edges or corners of a print start lifting or curling, resulting in uneven surfaces and poor adhesion. To address warping:

- Ensure that the print bed is leveled properly.

- Apply a suitable adhesive such as 3D printing glue stick or painter’s tape to improve adhesion.

- Consider using a heated bed or an enclosure to maintain a consistent printing temperature.

- Increase the bed temperature for better bed adhesion.

Inconsistent Print Quality

If you notice inconsistencies in print quality, such as gaps, layer shift, or stringing, the following solutions can help:

- Check the print settings and make sure they are optimized for the specific filament and object being printed.

- Ensure that the printer firmware and slicing software are up to date.

- Verify that the belts and pulleys are properly tensioned to prevent layer shift.

- Adjust the retraction settings to minimize stringing.

Regular maintenance and keeping your printer firmware and software updated are essential for troubleshooting common issues and ensuring optimal performance with your Creality 3D printer. By following these tips, you can overcome common challenges and achieve high-quality prints with your Creality printer.

| Common Issue | Solution |

|---|---|

| Filament Clogs | Check filament path and nozzle, adjust temperature, use high-quality filament |

| Warping | Check bed leveling, use adhesive, consider heated bed or enclosure, increase bed temperature |

| Inconsistent Print Quality | Optimize print settings, update firmware and software, check belt tension, adjust retraction settings |

Conclusion

Creality 3D printers are the ideal choice for both beginners and experienced users due to their exceptional quality, affordability, and user-friendliness. With a wide range of models and accessories, Creality caters to diverse printing needs and budgets. By following the tips and recommendations outlined in this guide, you can confidently select a Creality 3D printer and begin your exciting 3D printing journey.

Creality’s commitment to producing reliable printers with intuitive interfaces ensures a seamless and enjoyable printing experience. Whether you’re a hobbyist, a professional, or an educator, Creality has the perfect printer for you. Their extensive lineup includes the Ender 3 V3 SE, Ender 3 Neo, and the feature-packed Creality K1, all offering superior performance and impressive build quality.

Investing in a Creality 3D printer not only provides exceptional value but also grants you access to a vast collection of compatible accessories and upgrades. Enhance the capabilities of your printer by adding dual extruders, upgrading the hotend, or implementing an enclosure for better temperature control. These expansions and accessories allow you to push the boundaries of your creative projects.

In conclusion, Creality 3D printers are the go-to choice for individuals seeking reliable, affordable, and user-friendly devices. With a strong commitment to innovation and user satisfaction, Creality empowers users to bring their ideas to life with precision and ease. Start your printing journey with Creality and unlock endless possibilities in the world of 3D printing.