When it comes to precision machining solutions, Phantom CNC stands out as a leading provider in the industry. Their expertise and commitment to quality have made them a trusted name in the market.

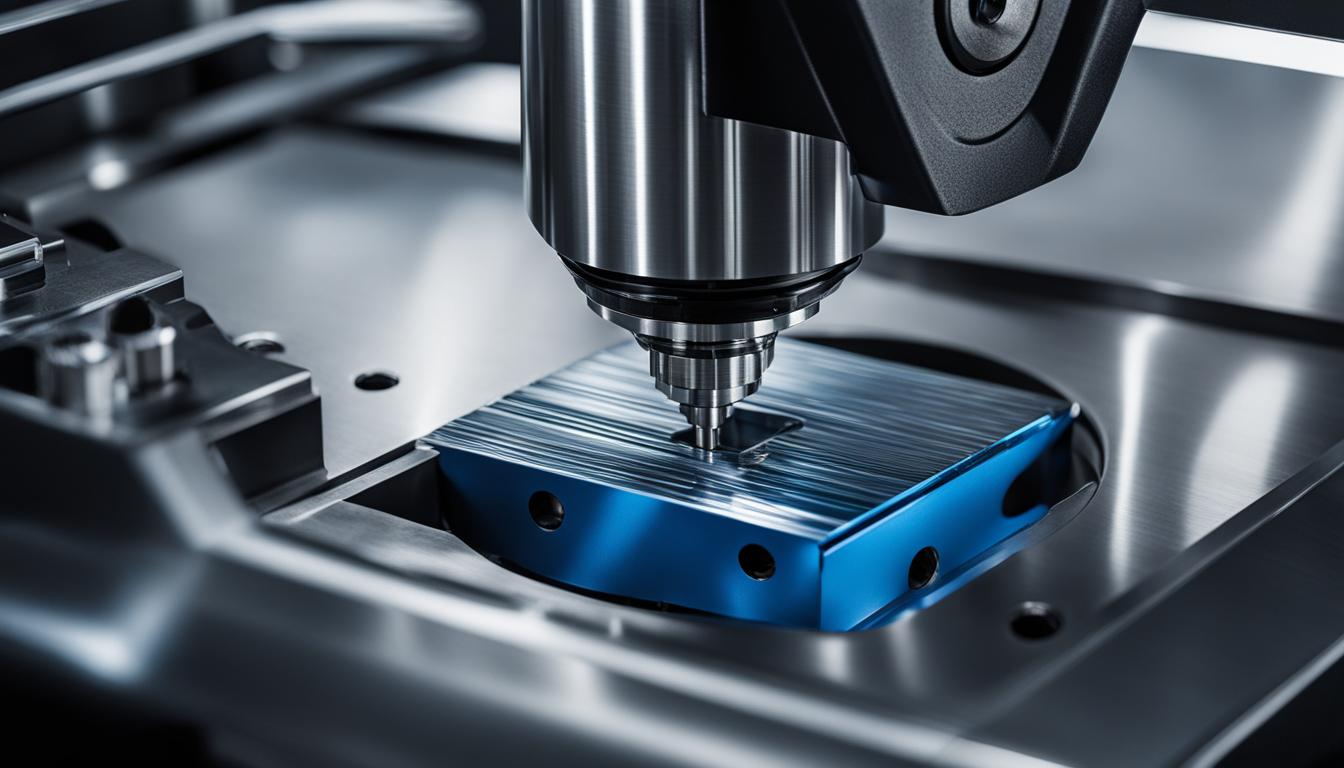

One of their latest offerings, the SCVATC Atomic series, has caught the attention of professionals in various industries. The CNC Router 4×4 with an automatic tool changer is a standout feature of this series, making it a top choice for precision machining needs.

What sets Phantom CNC apart is the exceptional sturdiness and quality of cuts that their machines deliver. The Atomic series machines may have a small footprint, but their performance is anything but small. With a tolerance of +/- 0.03 across 12 feet, these machines offer unparalleled accuracy for precise projects.

The construction of the SC CNC Series machines is another testament to Phantom CNC’s commitment to excellence. These machines feature a machine bed made from .180 mild steel square tube and industrial quality linear bearings with high precision rails on all axes.

Experience the precision and reliability of Phantom CNC systems for yourself and discover how their expertise can transform your manufacturing process.

Exceptional Performance and Durability

Customers and industry influencers have praised Phantom CNC machines for their exceptional performance and durability. Woodworking influencer Izzy Swan, with over 1 million followers, recently picked up the Phantom Atomic 4×4 CNC Router Machine and raved about its capabilities. According to Swan, the Phantom machine offers speeds comparable to $80,000 machines and can cut 500-600 inches per minute with a full depth of cut on three-quarter inch plywood. In comparison to other similar machines on the market, Phantom CNC offers significant cost savings without sacrificing quality.

Testimonial from Izzy Swan

“The Phantom Atomic 4×4 CNC Router Machine is an absolute game-changer. It performs like a machine that costs five times as much, but at a fraction of the price. I’m amazed at the precision and speed it offers. This machine has revolutionized my woodworking projects.”

To further understand the exceptional performance and durability of Phantom CNC machines, let’s take a look at a comparison table showcasing the key features, customer reviews, and cost savings:

| Features | Customer Reviews | Cost Savings | |

|---|---|---|---|

| Phantom CNC | – High cutting speeds – Precision depth of cut – Exceptional durability |

“Phantom CNC exceeded my expectations. It’s a powerhouse!” – Woodworking Enthusiast | Significant cost savings compared to similar machines on the market |

| Competitor A | – Lower cutting speeds – Less precision – Potential durability issues |

“The machine is decent, but lacks the speed and precision of Phantom CNC.” – Industry Professional | Higher upfront cost with potential maintenance and repair expenses |

| Competitor B | – Moderate cutting speeds – Inconsistent depth of cut – Typical durability |

“It’s an okay machine, but doesn’t match up to the performance of Phantom CNC.” – Hobbyist | Comparable upfront cost with fewer performance benefits |

As shown in the table, Phantom CNC machines outperform the competition with their exceptional features, positive customer reviews, and cost savings. Investing in a Phantom CNC machine not only ensures outstanding performance and durability but also delivers significant financial advantages.

Advanced Features and Versatility

The SC CNC Series machines from Phantom CNC offer advanced features and exceptional versatility, making them a top choice for precision machining in various industries. Equipped with state-of-the-art technology, these machines deliver outstanding performance and meet the diverse needs of different applications. Let’s take a closer look at the advanced features that set Phantom CNC machines apart:

Advanced Features

Phantom CNC machines are designed with cutting-edge features that enhance performance and ensure precision. Some of the notable features include:

- 9KW 12HP VFD Driven Air-Cooled Spindle: The SC CNC Series machines are equipped with a powerful 9KW 12HP VFD driven air-cooled spindle. This high-performance spindle allows for efficient and precise machining, delivering excellent results.

- ER32 Collets: The machines are fitted with ER32 collets, which provide a secure grip on the cutting tools. This ensures stability during the machining process, minimizing errors and improving accuracy.

- Effective Dust Collection Hood: Phantom CNC machines feature an effective dust collection hood that efficiently captures and removes dust particles. This helps maintain a clean and safe working environment while preventing dust buildup that could affect the machine’s performance.

- Pneumatic Rollers: The machines are equipped with pneumatic rollers that exert 600 lbs of downforce each. These rollers ensure materials stay firmly in place during cuts, minimizing vibrations and ensuring consistent and precise results.

Versatility and Customizability

Phantom CNC machines are highly versatile, allowing for customization of production capacity to suit specific needs. This flexibility makes them suitable for various industries, including aerospace, automotive, healthcare, electronics, and more. Whether you require intricate designs, complex cuts, or large-scale production, Phantom CNC machines offer the versatility and reliability needed to achieve exceptional results.

With their advanced features and unmatched versatility, Phantom CNC machines provide the ideal solution for precision machining projects in a wide range of industries. Whether you need a CNC router or a CNC milling machine, Phantom CNC has the perfect solution to meet your needs. Experience the power of advanced technology and take your machining capabilities to the next level with Phantom CNC.

Unparalleled Precision and Efficiency

When it comes to precision machining, Phantom CNC machines are in a league of their own. These machines offer unparalleled accuracy and efficiency, allowing manufacturers to achieve the highest quality results in their machining processes.

One of the key advantages of Phantom CNC machines is their ability to shorten machining times without compromising on precision. The cutting processes are designed to be swift and precise, delivering results that seem almost supernatural in their speed and accuracy. This not only saves valuable time but also reduces costs for manufacturers.

Another notable benefit of using Phantom CNC machines is the extensive tooling savings they offer. These machines have longer tool life, minimizing the need for frequent tool changes and reducing tooling costs. This means manufacturers can save money and optimize their machining operations.

In addition to precision and tooling savings, Phantom CNC machines are also designed with user-friendliness in mind. The setup and usage of these machines are made easy, allowing operators to navigate the machinery with simplicity and efficiency. This streamlines the manufacturing process and ensures smooth operations on the shop floor.

With their unparalleled precision, efficiency, and user-friendly design, Phantom CNC machines are an ideal choice for manufacturers looking to optimize their machining processes and achieve exceptional results.

The Benefits of Phantom CNC Machines:

- Unparalleled precision and accuracy

- Shortened machining times

- Extensive tooling savings

- User-friendly setup and usage

The All-American Story of Phantom CNC Systems

Phantom CNC Systems is not just a leading provider of CNC machining solutions, but it also has a fascinating origin story that exemplifies the American dream. The company was born in the backyard of owner Steve Wallace’s house on a farm in Vanceboro, North Carolina. From these humble beginnings, Phantom CNC has grown to become a trusted name in the industry, delivering high-quality machines and exceptional customer service.

At its facility in Vanceboro, all Phantom CNC machines undergo rigorous quality testing to ensure they meet the highest standards. The company leaves no stone unturned in guaranteeing the durability, precision, and reliability of their products. With plans for facility expansion to New Bern, North Carolina, in the works, Phantom CNC Systems continues to invest in growth and innovation, staying true to its commitment to American manufacturing.

With a strong foundation rooted in an All-American story, Phantom CNC Systems embodies the spirit of hard work, dedication, and the pursuit of excellence. Whether you’re looking for a phantom cnc jointer or exploring options within your price range, Phantom CNC has the perfect machine to meet your needs.

| Key Features: | Benefits: |

|---|---|

| High-quality construction | Ensures durability and longevity |

| Precision cutting | Produces accurate and consistent results |

| Advanced technology | Enables versatility and customization |

| Exceptional customer service | Supports clients throughout their machining journey |

Racer Machinery International’s Phantom Machine Technology

Racer Machinery International Inc. is revolutionizing the machine tool industry with their groundbreaking innovation known as Phantom Machine Technology. This cutting-edge technology transcends traditional machine tool manufacturing, offering numerous advantages for both the economy and the environment.

Phantom Machine Technology is designed to reduce pollutants and noise pollution, creating a safer and healthier workspace. With its outstanding performance, this technology enables shortened machining times, exceptional cutting performance, and unparalleled versatility in various production landscapes. The Phantom Machine Technology unlocks new possibilities and elevates the capabilities of CNC machines.

Let’s take a closer look at the remarkable benefits provided by Racer Machinery International’s Phantom Machine Technology:

Advantages of Phantom Machine Technology:

- Reduced pollutants and noise pollution for a safer and healthier workspace.

- Shortened machining times, resulting in increased productivity and efficiency.

- Astounding cutting performance for precision and accuracy.

- Versatility in various production landscapes, accommodating a wide range of applications.

Racer Machinery International’s Phantom Machine Technology is a game-changer in the machine tool industry. Not only does it enhance the productivity and precision of CNC machines, but it also contributes to a cleaner and more sustainable manufacturing environment.

Comparison Table: Phantom Machine Technology vs. Traditional Machine Tool Manufacturing

| Features | Phantom Machine Technology | Traditional Machine Tool Manufacturing |

|---|---|---|

| Reduced pollutants and noise pollution | ✓ | ✕ |

| Shortened machining times | ✓ | ✕ |

| Astounding cutting performance | ✓ | ✕ |

| Versatility in various production landscapes | ✓ | ✕ |

As demonstrated in the comparison table above, Phantom Machine Technology outshines traditional machine tool manufacturing in various aspects. With its innovative features and advanced capabilities, Phantom Machine Technology offers manufacturers a competitive edge in today’s dynamic market.

The Role of CNC Machine Builder Companies

CNC machine builder companies play a crucial role in the manufacturing industry, providing customized solutions to meet the specific needs of various sectors. One such company is Phantom CNC, known for its expertise in designing, assembling, and fine-tuning CNC machines. These companies excel in various areas to ensure the delivery of high-quality machines that optimize production processes and enhance overall efficiency. From design and engineering to manufacturing and assembly, these builders demonstrate their commitment to innovation, precision, and reliability.

Here are the key areas in which CNC machine builder companies like Phantom CNC excel:

Design and Engineering

Phantom CNC and similar companies invest heavily in research and development to design innovative machines that cater to the evolving needs of industries. Their engineering expertise ensures machines are optimized for performance, reliability, and ease of use. They employ cutting-edge technologies like CAD/CAM software and utilize their industry knowledge to create machines that maximize precision and efficiency.

Manufacturing and Assembly

With state-of-the-art facilities, CNC machine builder companies like Phantom CNC prioritize manufacturing and assembly processes to ensure seamless integration of components. They adhere to rigorous quality control measures, employing skilled technicians and machinists who meticulously assemble machines to the highest standards. By using premium materials and implementing advanced manufacturing techniques, these companies guarantee the durability and longevity of their products.

Integration of Electronics and Software

CNC machines rely on advanced electronics and software to achieve optimal performance. CNC machine builder companies, such as Phantom CNC, have expertise in integrating cutting-edge electronics and software solutions into their machines. They work closely with software developers and electronics experts to ensure seamless integration, allowing users to take full advantage of the machine’s capabilities and achieve superior results.

Calibration and Fine-Tuning

After the assembly process, CNC machine builder companies meticulously calibrate and fine-tune machines to ensure they perform at their best. They conduct extensive testing and quality assurance procedures to guarantee precise and accurate operation. Through meticulous calibration, these companies fine-tune the machines to deliver consistent and reliable performance, enabling users to achieve the desired results with utmost accuracy.

Testing and Quality Assurance

Phantom CNC and similar companies are committed to delivering high-quality machines. Through rigorous testing and quality assurance protocols, they ensure that every machine meets the highest industry standards. These companies subject their machines to comprehensive testing using advanced measurement tools and instruments to verify accuracy, repeatability, and overall performance. This dedication to quality ensures that customers receive machines that exceed their expectations.

Customer Training and Support

CNC machine builder companies provide comprehensive training and support to their customers. They understand that proper training is essential for users to unlock the full potential of their machines. These companies offer training programs tailored to the specific needs of their customers, ensuring they have the knowledge and skills to operate the machines efficiently. Additionally, they provide ongoing technical support to address any queries or issues that may arise, offering peace of mind to their customers.

Key Areas in which CNC Machine Builder Companies Excel

| Areas | Description |

|---|---|

| Design and Engineering | Investment in research and development to create innovative and optimized machines |

| Manufacturing and Assembly | Prioritization of quality control measures and premium materials for durable and reliable machines |

| Integration of Electronics and Software | Expertise in seamless integration of advanced electronics and software solutions |

| Calibration and Fine-Tuning | Meticulous calibration and fine-tuning to ensure precise and accurate operation |

| Testing and Quality Assurance | Rigorous testing and quality assurance protocols to ensure industry-standard performance |

| Customer Training and Support | Comprehensive training programs and ongoing technical support for customers |

CNC machine builder companies, like Phantom CNC, play a vital role in driving innovation, efficiency, and quality in the manufacturing industry. Their expertise in specialized machinery, commitment to innovation, and focus on quality and reliability make them key players in shaping the modern manufacturing landscape.

Benefits of CNC Machine Builder Companies

CNC machine builder companies play a crucial role in the manufacturing industry, offering a range of benefits to manufacturers. These companies specialize in designing and building CNC machines, tailoring them to specific industrial applications to ensure optimal performance and efficiency.

One of the key advantages of partnering with CNC machine builder companies is their expertise in specialized machinery. They are at the forefront of technological advancements in CNC machining, constantly pushing the boundaries of what’s possible. This expertise allows them to deliver machines that meet the specific needs and requirements of manufacturers, providing them with the cutting-edge technology necessary to stay competitive in today’s market.

Quality and reliability are paramount when it comes to CNC machines, and CNC machine builder companies prioritize both. They adhere to strict quality control measures, ensuring that their machines consistently perform at high levels and meet industry standards. By investing in a CNC machine from a reputable builder, manufacturers can have confidence in the reliability and durability of their equipment.

Furthermore, CNC machine builder companies offer comprehensive support throughout the entire lifecycle of the machines. This includes training on machine operation and maintenance, ensuring that manufacturers can maximize the capabilities of their CNC machines. These companies also provide ongoing maintenance, repairs, and upgrades, ensuring the longevity and productivity of the machines over time.

The Advantages of CNC Machine Builder Companies:

- Expertise in specialized machinery tailored to specific industrial applications

- Leadership in technological advancements in CNC machining

- Commitment to quality and reliability

- Comprehensive support, including training, maintenance, repairs, and upgrades

With the support of CNC machine builder companies, manufacturers can harness the power of CNC machining and unlock new levels of precision, efficiency, and productivity in their operations.

| Benefits | Explanation |

|---|---|

| Expertise in specialized machinery | These companies have in-depth knowledge and experience in designing and building CNC machines tailored to specific industrial applications, ensuring optimal performance and efficiency. |

| Technological advancements | CNC machine builder companies are at the forefront of technological advancements in CNC machining, constantly pushing the boundaries of what’s possible. |

| Quality and reliability | CNC machine builder companies prioritize quality and reliability, delivering machines that consistently perform at high levels and meet industry standards. |

| Comprehensive support | These companies provide ongoing training, maintenance, repairs, and upgrades, ensuring the longevity and productivity of CNC machines. |

By leveraging the expertise and support of CNC machine builder companies, manufacturers can enhance their operations, increase efficiency, and stay ahead in today’s competitive manufacturing landscape.

Embracing Precision and Possibilities with Phantom Machine Technology

Revolutionizing the machine tool industry, Phantom Machine Technology, developed by Racer Machinery International Inc., offers manufacturers a groundbreaking solution that unlocks precision, efficiency, and a world of possibilities. This cutting-edge technology is transforming the manufacturing landscape, delivering exceptional performance, reduced machining times, and extensive tooling savings.

Equipped with Phantom Machine Technology, CNC machines have become the epitome of precision and efficiency, making them the ideal choice for heavy-duty machining across various industries. With unparalleled accuracy and reliability, these machines pave the way for remarkable advancements in production capabilities.

The implementation of Phantom Machine Technology not only ensures superior craftsmanship but also brings significant cost savings. By optimizing machining times and maximizing tooling efficiency, manufacturers can streamline their processes and enhance overall productivity. This innovative technology empowers businesses to achieve higher quality outputs while minimizing production costs, ultimately driving competitiveness in the market.

Phantom Machine Technology is a game-changer, revolutionizing the manufacturing landscape. By embracing this cutting-edge technology, businesses can unlock the full potential of CNC machining, embracing precision and expanding possibilities like never before. Whether it’s the Phantom CNC Jointer or other Phantom CNC machines, this advanced technology empowers manufacturers to elevate their capabilities and achieve new heights of success in the ever-evolving manufacturing industry.