The Need for Renewable Energy and its Challenges

As the world’s population continues to grow, so does the demand for energy. We heavily rely on fossil fuels, which are finite resources that contribute significantly to climate change. Therefore, the need for renewable energy sources is more important than ever. Renewable energy, such as solar, wind, hydro, and geothermal power, is sustainable, abundant, and has a lesser impact on the environment. It also aids in reducing dependence on fossil fuels, enhancing energy security, and providing economic benefits.

However, harnessing renewable energy is not without its challenges. These include high costs, intermittency issues, limited efficiency, and difficulty in storing and transporting energy. Moreover, the manufacturing of renewable energy components often requires complex processes and high precision, which can be challenging to achieve.

CNC machining plays a crucial role in overcoming these challenges. It allows for high precision manufacturing of components, which is key to improving the efficiency and functionality of renewable energy systems. Additionally, CNC machining can also help reduce costs and waste in the production process, making renewable energy solutions more affordable and accessible.

A Closer Look at CNC Machining in Energy Sector

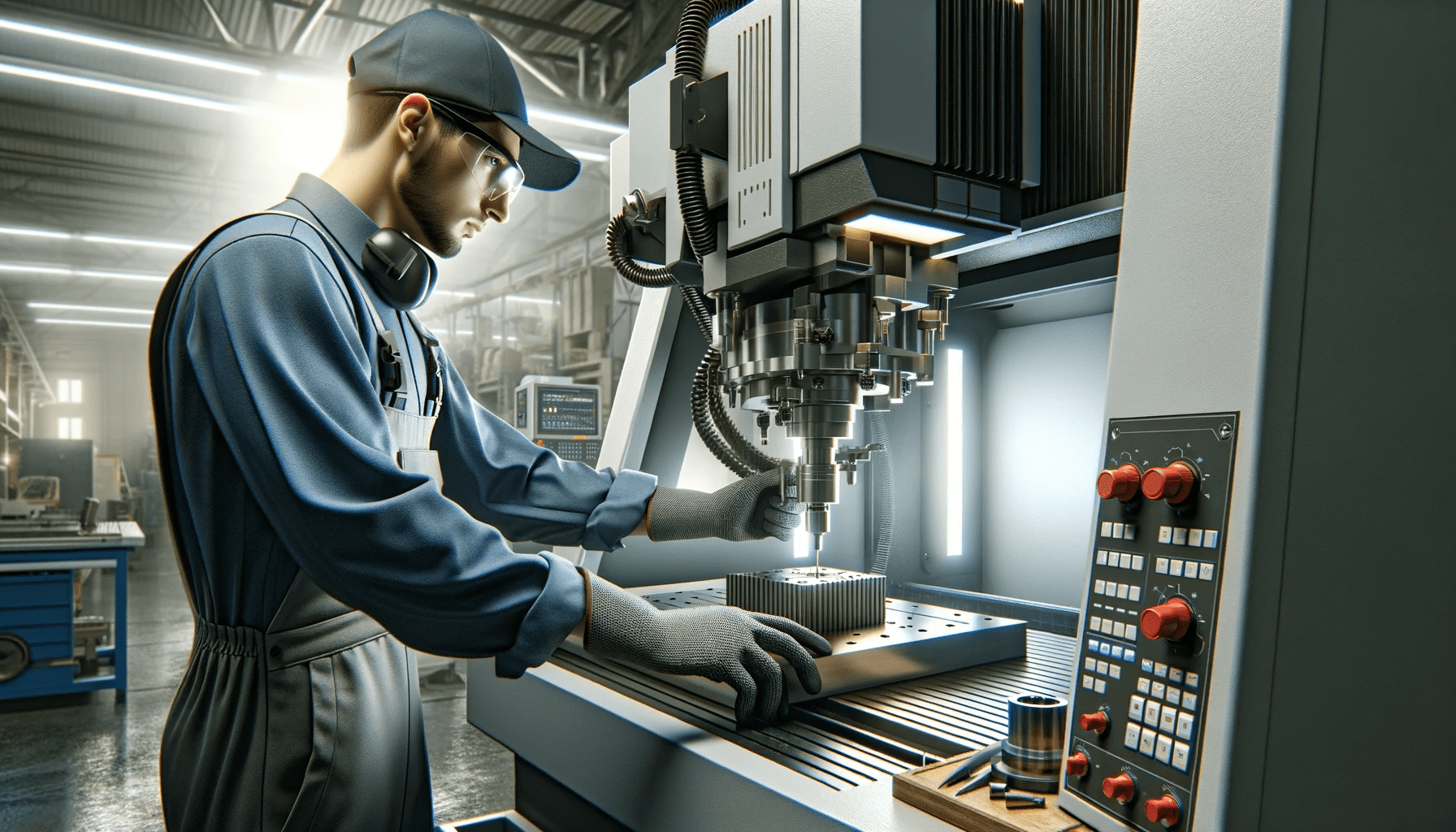

Computer Numerical Control (CNC) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

In the energy sector, CNC machining is used to manufacture precision components needed for various types of renewable energy systems. These include wind turbine blades, solar panel components, hydropower turbines, geothermal energy converters, and more. The intricate and precise nature of these components makes CNC machining an ideal solution.

Furthermore, CNC machining allows for rapid prototyping, which can help speed up the development and testing of new renewable energy technologies. This not only accelerates innovation in the sector but also helps to reduce costs and improve efficiency.

CNC Machining in Wind Energy Production

Wind energy is a key player in the renewable energy sector, providing a clean and abundant power source. The main component of a wind energy system is the wind turbine, which converts wind power into electricity. The manufacturing of wind turbines requires high precision and a high level of quality control, which CNC machining can provide.

Wind turbine blades are typically made from composite materials and must be produced with a high degree of accuracy to ensure optimal performance. CNC machining allows for the precise cutting and shaping of these blades, enabling them to capture wind energy more efficiently. Furthermore, CNC machining can also be used in the production of other wind turbine components, such as the gearbox and generator.

Moreover, the use of CNC machining in wind energy production can help reduce waste, as it allows for more accurate cutting and less material usage. This not only helps to reduce costs but also contributes to the sustainability of wind energy production.

Role of CNC Machining in Solar Energy Components

Solar energy is another crucial source of renewable energy. It harnesses the power of the sun to generate electricity. The key component in solar energy systems is the solar panel, which consists of several solar cells that convert sunlight into electricity. The production of these solar cells and panels requires high precision and a strict adherence to quality standards.

CNC machining plays a vital role in the manufacturing of solar panels. It is used to cut and shape the solar cells and to assemble the panels. With CNC machining, the production process can be automated and standardized, ensuring consistent quality and high efficiency.

Additionally, CNC machining can also help reduce waste in solar panel manufacturing. By optimizing the cutting process, less material is wasted, which can help reduce costs and make solar energy more affordable.

Contribution of CNC Machining in Hydropower Energy

Hydropower energy, which generates power through the movement of water, is one of the oldest and most reliable forms of renewable energy. The key components in hydropower systems are the turbines, which convert the kinetic energy of flowing water into mechanical energy.

CNC machining is used to manufacture these turbines, as it allows for high precision and consistency. The blades of the turbines need to be cut and shaped accurately to ensure optimal performance. CNC machining can achieve this level of accuracy, which can contribute to the efficiency and reliability of hydropower systems.

Moreover, CNC machining can also be used in the production of other hydropower components, such as the generators and control systems. This further enhances the role of CNC machining in the hydropower sector.

Precision and Efficiency: CNC in Geothermal Energy

Geothermal energy harnesses the heat from the earth to generate electricity. This type of energy requires specific equipment to extract the heat and convert it into usable power. The key components of geothermal energy systems are the heat exchangers, pumps, and turbines, all of which require high precision in their manufacture.

CNC machining is often used in the production of these components. It allows for the accurate cutting and shaping of the parts, ensuring that they function effectively and efficiently. Furthermore, the ability of CNC machining to produce components with strict tolerances contributes to the reliability and longevity of geothermal energy systems.

Additionally, the use of CNC machining in geothermal energy production can help reduce waste and costs. By optimizing the manufacturing process, less material is used, and the production time is reduced, making geothermal energy more cost-effective and sustainable.

CNC Machining in the Manufacturing of Energy Storage Devices

Renewable energy generation often faces the challenge of intermittency, as the availability of wind, sun, and water fluctuates. Therefore, energy storage devices, such as batteries and capacitors, play a vital role in ensuring a steady supply of energy.

CNC machining is used in the manufacturing of these energy storage devices. It allows for the precise and efficient production of the components, such as the battery casing and the electrodes. This not only ensures the functionality and performance of the devices but also contributes to their longevity and safety.

Moreover, with CNC machining, the production process can be automated, which can help increase the production speed and reduce costs. This can make energy storage solutions more accessible and affordable, contributing to the advancement of the renewable energy sector.

Implementing CNC Machining in Bioenergy Production

Bioenergy involves the conversion of biomass materials, such as wood and agricultural waste, into energy. This process requires specific equipment, such as bioreactors and boilers, which need to be manufactured with high precision.

CNC machining is used in the production of these bioenergy components. It allows for the accurate cutting and shaping of the parts, ensuring their performance and efficiency. Additionally, CNC machining can also be used in the production of the tools needed for biomass processing, such as chippers and shredders.

Furthermore, the use of CNC machining in bioenergy production can help reduce costs and waste. By optimizing the production process, less material is used, and the production time is reduced. This can contribute to the sustainability and affordability of bioenergy.

Challenges and Solutions in CNC Machining for Renewable Energy

While CNC machining plays a crucial role in the renewable energy sector, it is not without its challenges. These include the need for skilled operators, the high cost of CNC equipment, and the difficulty in machining certain materials, such as composite materials used in wind turbine blades.

However, these challenges can be addressed through ongoing advancements in CNC technology. For instance, the development of more user-friendly CNC software can help reduce the need for skilled operators. Additionally, the introduction of more affordable CNC machines can make the technology more accessible to smaller manufacturers.

Moreover, ongoing research and development in CNC machining technology can help improve the machining of complex materials. This can enhance the production of renewable energy components and contribute to the advancement of the sector.

Future Prospects of CNC Machining in Renewable Energy

The future of renewable energy relies heavily on advancements in technology, and CNC machining is at the forefront of this progress. As the demand for renewable energy continues to grow, so does the need for high-quality and efficient components.

CNC machining is expected to play an increasingly important role in the renewable energy sector. With ongoing advancements in CNC technology, the precision and efficiency of the manufacturing process will continue to improve. This can help increase the performance and reliability of renewable energy systems, making them more accessible and affordable.

Furthermore, as renewable energy technologies continue to evolve, new applications for CNC machining are likely to emerge. This includes the production of components for emerging renewable energy technologies, such as tidal and wave power systems.

In conclusion, CNC machining is playing a crucial role in powering the future of renewable energy. Its ability to manufacture high-precision components efficiently and affordably is contributing significantly to the advancement of the sector.