Aluminum machining services play a crucial role in various industries that require precision and quality. Precision CNC milling and turning processes are used to fabricate aluminum parts with accuracy and efficiency. With its desirable qualities such as corrosion resistance, electrical conductivity, and high strength-to-weight ratio, aluminum is a versatile material widely used in industries like aerospace, defense, automotive, and electronics.

From automotive engine components to EMI shield housings and splined shafts, precision CNC machined aluminum parts are in high demand. CNC milling and turning of aluminum enables the creation of complex shapes and precise dimensions, ensuring the highest level of performance and functionality. Trustworthy aluminum machining services offer the expertise and equipment required for custom aluminum fabrication projects.

To achieve the desired results, it is important to choose the right aluminum alloy for CNC machining. Aluminum alloys like 6061, 7075, and 2024 are commonly used for their high strength and corrosion resistance. Custom aluminum machining services assist in selecting the most suitable alloy based on the project’s specific requirements.

Whether it’s precision CNC milling, CNC turning, or other aluminum machining solutions, the importance of aluminum in CNC machining cannot be overstated. Its lightweight, machinability, thermal and electrical conductivity, and recyclability make it an ideal choice for various applications. Professional CNC aluminum machining services provide comprehensive solutions for custom aluminum parts, delivering top-quality results with fast turnaround times.

Aluminum Machining Solutions

Aluminum machining solutions offer comprehensive options for custom, high-quality fabrication in various industries. By utilizing CNC milling and turning processes, these solutions provide precision and accuracy in manufacturing aluminum parts with intricate designs. These solutions also offer flexibility, allowing for the fabrication of components using different aluminum alloys such as AA-6061 and AA-7075.

One of the key advantages of aluminum machining solutions is their ability to cater to specific design needs. With CNC milling, intricate shapes and complex geometries can be achieved with ease. Similarly, CNC turning allows for the creation of cylindrical or round components. The combination of these machining processes ensures precise dimensions and tight tolerances for aluminum parts.

Moreover, aluminum machining solutions extend beyond the manufacturing process. Post-machining finishes such as anodizing and powder coating can be applied to enhance the aesthetic appeal and overall durability of aluminum parts.

The Importance of Aluminum Fabrication

Aluminum fabrication plays a crucial role in numerous industries, including aerospace, automotive, and electronics. Its lightweight nature combined with its exceptional strength-to-weight ratio makes it an ideal material choice for various applications. Moreover, aluminum’s corrosion resistance and high electrical conductivity further contribute to its suitability for a wide range of manufacturing needs.

When it comes to CNC aluminum milling, precision and versatility are paramount. CNC machines can accurately shape and mill aluminum stock into intricate components, ensuring consistent quality and dimensional accuracy throughout the manufacturing process. This level of precision is essential in industries where tight tolerances and high-quality standards are required.

Overall, aluminum machining solutions provide the necessary expertise and technology to meet the demanding requirements of aluminum fabrication. By offering a range of machining processes and the ability to work with different aluminum alloys, these solutions ensure the production of custom, high-quality aluminum parts for diverse industries.

| Advantages of Aluminum Machining Solutions | Applications |

|---|---|

| 1. Precision and Accuracy | Aerospace |

| 2. Versatility in Design | Automotive |

| 3. Handling of Various Aluminum Alloys | Electronics |

| 4. Post-Machining Finishes | Industrial |

Advantages of CNC Aluminum Machining

CNC aluminum machining offers numerous advantages in the manufacturing industry. When it comes to machining aluminum, precision and efficiency are crucial. Let’s explore the key benefits of CNC aluminum machining:

1. Excellent Corrosion Resistance

Aluminum exhibits remarkable corrosion resistance, making it ideal for various applications, particularly in industries where exposure to harsh environments is common. CNC machining processes ensure that the aluminum parts retain their corrosion-resistant properties, even after intricate machining.

2. High Strength-to-Weight Ratio

Aluminum boasts a high strength-to-weight ratio, making it a popular choice for lightweight structural applications. It allows manufacturers to produce strong and durable components while minimizing weight. This advantage is particularly significant in industries such as aerospace and automotive, where weight reduction is a priority.

3. Good Heat and Electrical Conductivity

One of the notable characteristics of aluminum is its excellent heat and electrical conductivity. This property is highly valued in industries that require efficient heat dissipation or electrical conductivity, such as electronics and power transmission. CNC aluminum machining ensures that these conductivity properties are preserved during the manufacturing process.

4. Creation of Complex Shapes and Precise Dimensions

Aluminum turning and precision CNC milling techniques enable the creation of complex shapes and precise dimensions. CNC machines offer high accuracy and repeatability, allowing manufacturers to achieve intricate designs and tight tolerances. This versatility is invaluable when producing custom aluminum components.

5. High-Quality Machined Aluminum Components

The combination of CNC machines and skilled operators in aluminum milling and turning services guarantees the production of high-quality machined components. Skilled operators can carefully monitor and control the machining process, ensuring that the final products meet the required specifications and quality standards.

With these advantages in mind, it’s clear why CNC aluminum machining is a preferred choice for manufacturing industries. The ability to produce corrosion-resistant, lightweight, and precise components contributes to the overall efficiency and reliability of the end products.

| Advantages of CNC Aluminum Machining |

|---|

| Excellent Corrosion Resistance |

| High Strength-to-Weight Ratio |

| Good Heat and Electrical Conductivity |

| Creation of Complex Shapes and Precise Dimensions |

| High-Quality Machined Aluminum Components |

CNC Machining Materials for Aluminum

CNC machining offers a wide range of possibilities for aluminum fabrication. Various aluminum alloys can be used to create custom machined parts, each with its own unique properties and characteristics. Here are some of the most commonly used aluminum alloys in CNC machining:

| Alloy | Properties |

|---|---|

| 6061 | Excellent strength, good corrosion resistance, weldable |

| 7075 | High strength, good fatigue resistance, poor weldability |

| 7050 | High strength, good toughness, stress corrosion cracking resistance |

| 2024 | High strength, good machinability, poor corrosion resistance |

| 5052 | Good formability, excellent corrosion resistance, weldable |

| 6063 | Good heat dissipation, excellent extrudability, good corrosion resistance |

Each alloy offers different advantages depending on the specific application. For example, alloys like 6061 and 5052 are commonly used in the automotive industry for their strength and corrosion resistance. On the other hand, alloys like 2024 and 7075 are popular choices for aerospace applications due to their high strength and lightweight properties. Custom aluminum machining allows for the selection of the most suitable alloy based on the desired performance and functionality.

With a diverse range of aluminum alloys available, CNC machining provides the flexibility to meet the unique requirements of various industries and applications. Whether it’s automotive, aerospace, electronics, or any other industry, CNC machining materials for aluminum offer precision, durability, and versatility.

Precision CNC Machining Services

Precision CNC machining services play a crucial role in the manufacturing industry, particularly in aluminum machining. These services offer high-precision dimensions based on mechanical engineering drawings, ensuring the production of custom aluminum parts with accuracy and efficiency.

When it comes to aluminum machining, precision is of utmost importance. Skilled engineers and technicians are trained to provide design and technical support throughout the machining process, guaranteeing that the final product meets the client’s specifications.

Precision CNC machining services for aluminum encompass a range of processes, including:

- CNC milling: This process removes material from the aluminum stock using rotary cutting tools, creating complex shapes and precise dimensions.

- CNC lathe: The CNC lathe rotates the aluminum stock against cutting tools, allowing for the creation of cylindrical components.

- CNC turning: Similar to CNC lathe, CNC turning is used to shape the aluminum stock into various geometries.

- EDM (Electrical Discharge Machining): This process employs electrical discharges to shape and cut aluminum with high precision.

The combination of these processes ensures that precision CNC machining services can cater to the needs of different industries. Whether it’s automation, automotive, aerospace, or any other sector, custom aluminum parts can be manufactured to meet specific requirements.

To visualize the importance of precision CNC machining services in aluminum fabrication, here’s a table showcasing the typical industries and applications that benefit from these services:

| Industry | Applications |

|---|---|

| Aerospace | Aircraft components, structural parts, engine parts |

| Automation | Robotics, industrial machinery |

| Automotive | Engine components, transmission parts, chassis |

| Electronics | Electronic enclosures, heat sinks, connectors |

| Medical | Surgical instruments, implants, medical equipment |

Benefits of CNC Aluminum Machining

CNC aluminum machining offers numerous advantages, making it a preferred choice in various industries. Whether it’s creating intricate designs or manufacturing lightweight components, aluminum machining delivers exceptional results. Let’s explore the key benefits of CNC aluminum machining:

1. Accuracy and Repeatability

CNC aluminum machining provides precise and consistent results, ensuring accuracy in creating complex shapes and intricate designs. The advanced computer-controlled technology allows for high levels of precision, meeting strict dimensional requirements with ease.

2. Environmentally Friendly

Aluminum machining is an environmentally friendly process that produces no harmful emissions or waste products. With sustainability becoming increasingly important, choosing aluminum fabrication solutions contributes to a greener future.

3. High Strength-to-Weight Ratio

Aluminum has a remarkable strength-to-weight ratio, making it ideal for lightweight applications. By using aluminum machining solutions, manufacturers can create durable, yet lightweight, components that can withstand demanding conditions.

4. Easy Machinability

Aluminum is known for its excellent machinability, allowing for efficient and cost-effective manufacturing processes. Its soft and malleable nature makes it easy to work with, enabling the production of intricate parts with minimal tool wear.

5. Reflective Properties

Aluminum has exceptional reflective properties, making it ideal for applications that require heat and light reflection. This feature is particularly beneficial in industries such as automotive and aerospace, where thermal management is crucial.

6. Recyclable Material

As a recyclable material, aluminum contributes to sustainable practices and reduces environmental impact. By choosing CNC aluminum machining, manufacturers can support the circular economy and reduce waste.

| Benefit | Description |

|---|---|

| Accuracy and Repeatability | Precise and consistent results for complex shapes and intricate designs. |

| Environmentally Friendly | No harmful emissions or waste products. |

| High Strength-to-Weight Ratio | Durable yet lightweight components. |

| Easy Machinability | Efficient and cost-effective manufacturing processes. |

| Reflective Properties | Ideal for applications requiring heat and light reflection. |

| Recyclable Material | Contributes to sustainability and reduces waste. |

Choosing the Right Aluminum for CNC Machining

When it comes to CNC machining, selecting the suitable aluminum alloy is crucial for achieving desired results. Different aluminum alloys possess varying properties that make them ideal for specific applications. Factors such as strength, corrosion resistance, weldability, formability, and heat treatability should be taken into account when choosing the right aluminum for CNC machining.

Commonly Used Aluminum Alloys for CNC Machining

Several aluminum alloys are commonly used in CNC machining due to their favorable characteristics. These include:

- 6061: Known for its high strength and good corrosion resistance, 6061 is a versatile alloy used in various industries.

- 7075: Considered one of the strongest aluminum alloys, 7075 is often used in aerospace and high-stress applications.

- 2024: This alloy offers excellent machinability and good strength, making it suitable for precision parts and components.

While these alloys are popular choices, custom aluminum machining services can provide guidance in selecting the most suitable alloy based on specific project requirements.

CNC machining providers have extensive knowledge and experience in working with different aluminum alloys. They understand the unique properties of each alloy and can recommend the best option to achieve the desired mechanical and physical properties in the final product.

By collaborating with custom aluminum machining services, manufacturers can ensure that their CNC machined aluminum components meet the highest quality standards and perform optimally in their designated applications.

CNC Milling and Turning Aluminum Process

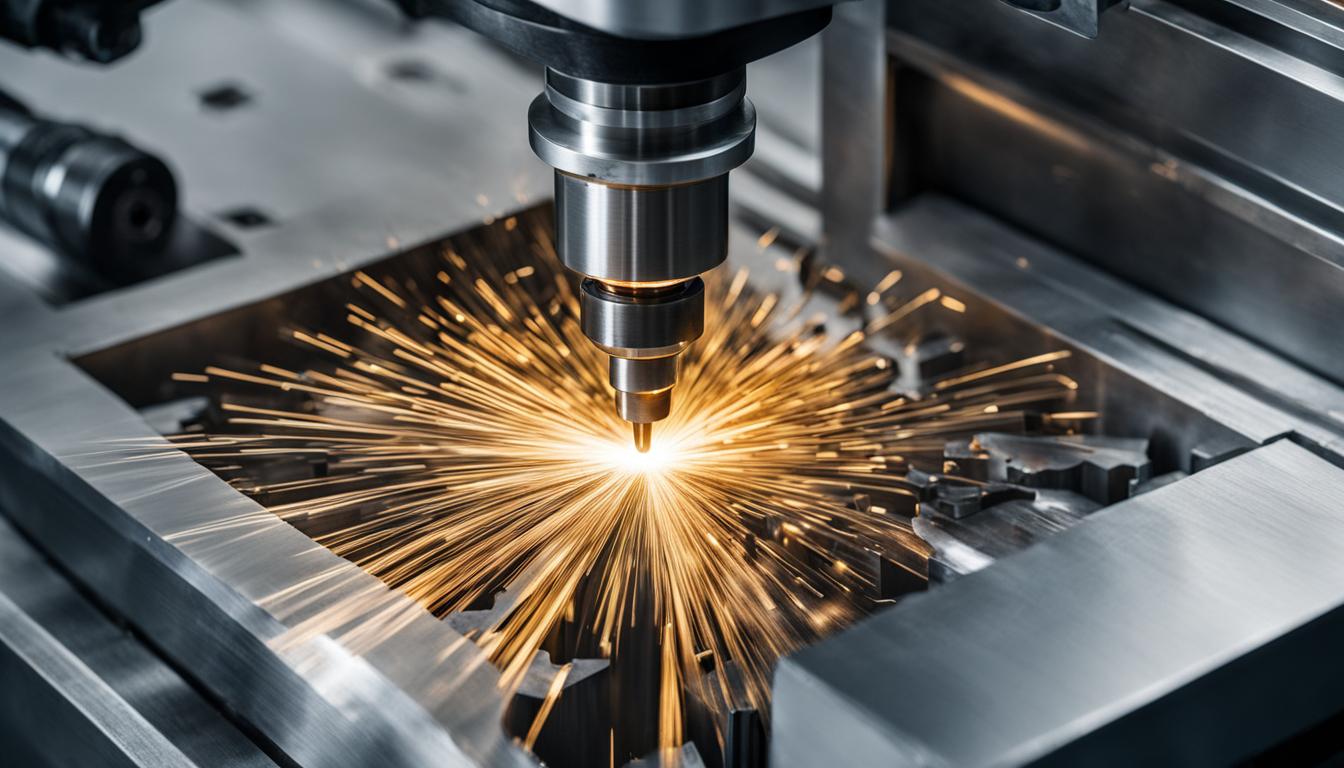

The CNC milling and turning process for aluminum is a highly precise and efficient method of shaping aluminum stock into the desired components. It involves the use of advanced CNC machines equipped with rotary cutting tools to remove material and shape the aluminum stock.

During CNC milling, the rotating cutting tools remove excess material from the aluminum stock, creating the desired shape and dimensions. This process allows for intricate designs and precise tolerances to be achieved.

CNC turning, on the other hand, involves rotating the aluminum stock against cutting tools to shape it into the desired form. This technique is particularly effective for creating cylindrical or conical components with tight tolerances.

The CNC milling and turning processes are ideal for aluminum machining due to the material’s excellent machinability and versatility. These processes can produce complex shapes and achieve tight tolerances, ensuring accurate and high-quality aluminum components for various industries and applications.

Take a look at the table below, which highlights the key differences between CNC milling and turning for aluminum:

| CNC Milling | CNC Turning |

|---|---|

| Rotary cutting tools remove excess material | Aluminum stock is rotated against cutting tools |

| Suitable for complex shapes | Ideal for cylindrical or conical components |

| Precise and tight tolerances | Accurate and high-quality results |

With CNC milling and turning services for aluminum, manufacturers can achieve efficient and accurate machining for various applications. Whether it’s automotive parts, aerospace components, or electronics enclosures, CNC machining offers the precision and reliability required for quality aluminum products.

Next, let’s explore the capabilities of professional CNC aluminum machining services and how they can provide comprehensive solutions for your aluminum machining needs.

Professional CNC Aluminum Machining Service

When it comes to precision machining of aluminum parts, professional CNC machining services offer comprehensive solutions to meet the exact specifications of your project. From custom designs to high-volume production, these services utilize advanced technologies and expertise to deliver top-quality results. Whether you need CNC milling, CNC turning, EDM, or anodizing surface treatment, professional CNC aluminum machining services have you covered.

With a team of skilled engineers and technicians, these services provide unparalleled design and technical support throughout the entire manufacturing process. They work closely with you to understand your requirements and ensure that every detail is meticulously executed. From initial concept to final production, their expertise and attention to detail guarantee the highest level of precision and accuracy.

Professional CNC aluminum machining services are equipped to handle both large-volume orders and small-scale productions, making them suitable for a wide range of industries and applications. They have the capacity and capability to meet fast turnaround times, ensuring that your projects are delivered on time and within budget. Furthermore, these services have no minimum quantity requirements, allowing for flexibility and efficiency in fulfilling your machining needs.

By choosing a professional CNC aluminum machining service, you can leverage their expertise and experience to achieve outstanding results. With their state-of-the-art equipment and advanced machining techniques, they can deliver custom aluminum parts that meet the highest industry standards. Whether you require intricate components or complex geometries, these services have the technical prowess to bring your designs to life.

The Benefits of Professional CNC Aluminum Machining Services:

- Comprehensive machining solutions for aluminum parts

- Advanced CNC milling, turning, EDM, and anodizing capabilities

- Skilled engineers and technicians providing design and technical support

- Accurate and precise manufacturing processes

- Fast lead times and flexible production capabilities

- No minimum quantity requirements

When it comes to aluminum machining, trust the professionals to deliver superior results. With their expertise, state-of-the-art equipment, and commitment to quality, professional CNC aluminum machining services are the ideal choice for your machining needs.

| Benefits of Professional CNC Aluminum Machining Services |

|---|

| Comprehensive machining solutions for aluminum parts |

| Advanced CNC milling, turning, EDM, and anodizing capabilities |

| Skilled engineers and technicians providing design and technical support |

| Accurate and precise manufacturing processes |

| Fast lead times and flexible production capabilities |

| No minimum quantity requirements |

Importance of Aluminum in CNC Machining

Aluminum is a popular choice for CNC machining due to its unique properties and versatility. It offers a range of benefits that make it highly suitable for various applications.

- Lightweight: Aluminum is lightweight, making it ideal for applications where weight is a concern. It allows for the creation of lightweight and portable products without compromising on strength and durability.

- Strength: Despite its lightweight nature, aluminum is surprisingly strong. It offers excellent structural integrity and can withstand heavy loads, making it suitable for applications that require strength and performance.

- Machinability: Aluminum is easily machinable, allowing for the creation of intricate and complex designs. CNC machining processes can achieve high levels of precision and accuracy, resulting in high-quality aluminum components.

- Thermal and Electrical Conductivity: Aluminum has excellent thermal and electrical conductivity, making it an ideal choice for applications that require efficient heat transfer or electrical conductivity.

- Corrosion Resistance: Aluminum exhibits excellent corrosion resistance, making it suitable for outdoor or corrosive environments. It does not easily rust or corrode, ensuring the longevity of machined aluminum parts.

- High Strength-to-Weight Ratio: Aluminum has a high strength-to-weight ratio, making it an excellent choice for applications where weight reduction is important without compromising strength and performance.

- Recyclability: Aluminum is a highly recyclable material. It can be recycled and reused multiple times without a loss in quality, making it an environmentally friendly choice for CNC machining.

Aluminum machining services are vital in manufacturing industries that require precision, reliability, and the ability to create custom components. By leveraging the properties of aluminum, CNC machining can deliver high-quality and efficient solutions for a wide range of applications.

CNC Machining Aluminum: Cutting Techniques

When it comes to CNC machining aluminum, cutting techniques play a vital role in achieving precise results. Depending on the specific requirements of the project, a variety of tools can be used to cut and shape aluminum with precision. These tools include milling machines, drill presses, and CNC routers.

One key factor to consider is the type of aluminum alloy being machined. Different alloys may require specific cutting tools and techniques to achieve the desired results. For example, softer alloys may be more easily cut using high-speed tools, while harder alloys may require the use of carbide or diamond-tipped tools for efficient cutting.

Proper planning and precise machining are essential for successfully cutting aluminum using CNC techniques. This includes carefully determining the cutting speed, feed rate, and tool geometry to optimize the machining process. By employing the right tools and techniques, aluminum turning, milling, and CNC machining services can deliver high-quality results for various applications.