While CNC machines offer numerous advantages in manufacturing, they also come with significant drawbacks. The high initial cost of purchasing and installing CNC equipment can be prohibitive for smaller businesses or those with limited capital. This substantial investment includes not only the machine itself but also the necessary software and training for operators. Another key disadvantage is the complexity of programming and maintaining CNC machines, which requires specialized skills and knowledge.

Operators must be well-versed in G-code programming and machine operation, leading to increased training costs and potential downtime if skilled personnel are unavailable. Lastly, CNC machines are heavily dependent on electricity and computer systems, making them vulnerable to power outages and software glitches. These issues can result in production delays, increased maintenance costs, and potential loss of data or work in progress. Despite these challenges, many manufacturers find that the benefits of CNC technology outweigh these disadvantages, particularly in terms of precision, efficiency, and consistency in production.

Higher Cost Compared to Other Methods

When considering CNC machining for a project, it’s important to be aware of one of its common drawbacks: higher cost compared to other manufacturing methods. CNC machines can be more expensive upfront, making them less affordable for some businesses. However, it’s crucial to understand that this cost is justified by the added accuracy and precision that CNC machining offers.

While other manufacturing methods may have lower upfront costs, they may lack the precision and consistency that CNC machining can provide. The higher cost of CNC machines is often a trade-off for superior quality and the ability to produce complex designs with tight tolerances. Ultimately, the decision to choose CNC machining should be based on the specific requirements of the project and the value placed on precision and high-quality results.

It’s essential to consider the total cost of CNC machining, including factors such as maintenance, operator training, and material costs. While CNC machining may have a higher initial investment, it can provide long-term cost savings through increased efficiency and reduced material waste. By carefully weighing the benefits against the higher cost, businesses can make informed decisions about whether CNC machining is the right choice for their manufacturing needs.

| Advantages | Disadvantages |

|---|---|

| High accuracy | Higher cost compared to other methods |

| Precision machining | Size limitations for larger parts |

| Complex design capabilities | Regular maintenance requirements |

| Efficient and consistent production | Need for skilled operators and programming knowledge |

| Reduced material waste | Limited material options |

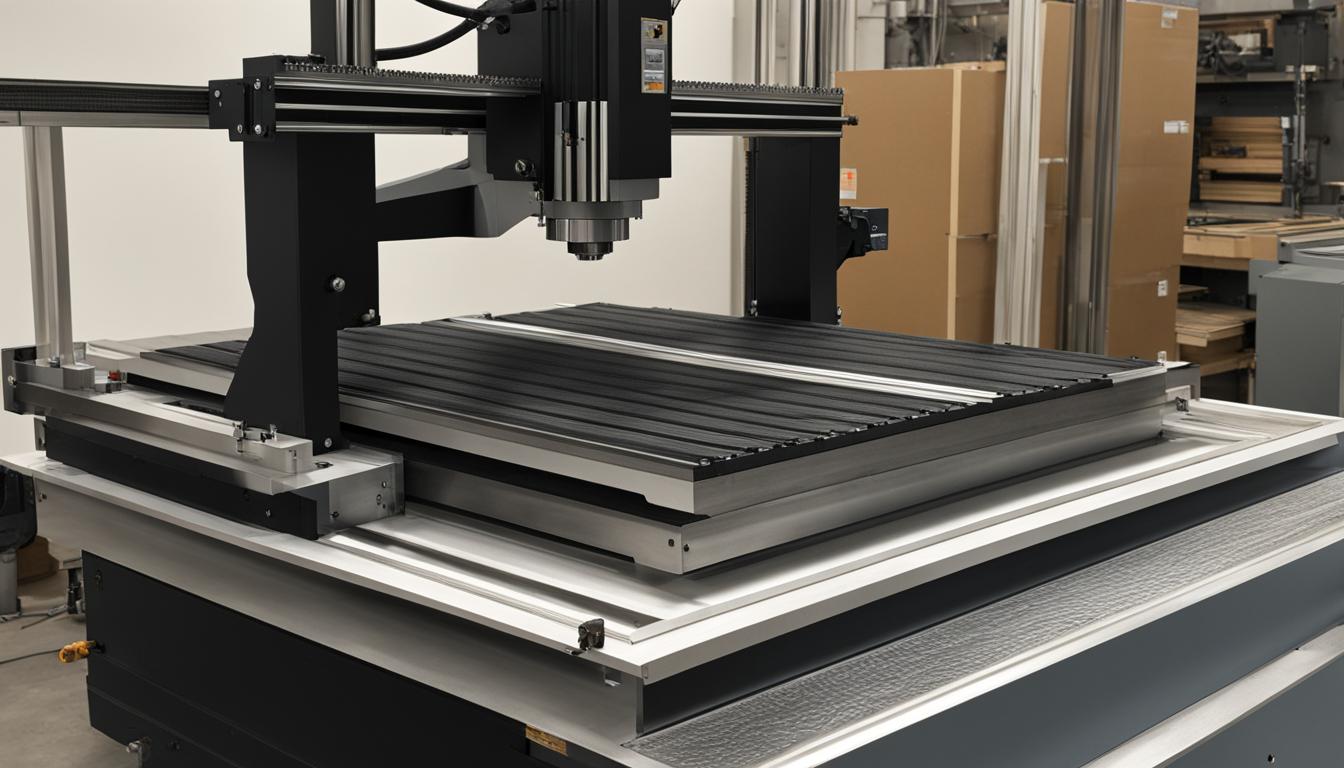

Size Limitations of CNC Machines

CNC machines offer precision and accuracy in machining, but they also have size limitations that can impact certain projects. It’s important to consider these limitations when deciding whether CNC machining is the right option for your needs.

Many CNC machines have restrictions on the size of the workpiece that can be accommodated. For example, CNC milling machines may have a limited workspace or a maximum table size that cannot be exceeded. This can be problematic when working with larger parts that require machining.

Before opting for CNC machining, it’s crucial to carefully evaluate the size requirements of your project and ensure that the CNC machine you choose can accommodate them. This may involve discussing the specific dimensions with the machine shop and confirming that they have the necessary equipment to handle the size of your workpiece.

Table: Maximum Workpiece Dimensions for CNC Machines

| CNC Machine Type | Maximum Workpiece Length | Maximum Workpiece Width | Maximum Workpiece Height |

|---|---|---|---|

| CNC Milling Machine | 30 inches | 20 inches | 10 inches |

| CNC Lathe | 18 inches | 10 inches | N/A |

| CNC Router | 48 inches | 48 inches | 6 inches |

The table above provides an example of the maximum workpiece dimensions for different types of CNC machines. These dimensions can vary depending on the specific machine and manufacturer, so it’s essential to consult with the machine shop to determine their capabilities.

By understanding the size limitations of CNC machines and carefully considering the requirements of your project, you can make an informed decision about whether CNC machining is the right choice for your manufacturing needs.

High Maintenance Requirements

Proper maintenance is crucial for keeping CNC machines running optimally. Neglecting maintenance can lead to inaccurate machining results or even machine failures. Regular cleaning, checking coolant levels, and servicing the machine are essential tasks to ensure smooth and uninterrupted operations.

CNC machine maintenance involves performing routine inspections and preventive measures. This includes lubricating moving parts, checking for wear and tear, and calibrating the machine for accuracy. Scheduled maintenance should be carried out based on the manufacturer’s recommendations and usage frequency.

It is important to note that maintenance costs are an additional consideration when opting for CNC machining. Depending on the complexity and size of the machine, maintenance costs can vary. Regular maintenance not only enhances the longevity of the machine but also helps avoid costly repairs or replacements in the future.

| Maintenance Tasks | Frequency | Costs |

|---|---|---|

| Cleaning and lubrication | Weekly | Low |

| Checking coolant levels | Weekly | Low |

| Inspecting and replacing worn parts | Monthly | Medium |

| Calibration and alignment | Quarterly | High |

By investing time and resources in regular maintenance, CNC machine owners can ensure the longevity and optimal performance of their machines. It is important to factor in the maintenance requirements and associated costs when considering CNC machining as a manufacturing method.

Need for Skilled Operators and Programming Knowledge

One of the key challenges of CNC machining is the requirement for skilled operators who possess proficient programming knowledge. Operating a CNC machine involves various technical aspects, including programming the machine to perform precise movements and execute complex tasks. Skilled operators are essential to ensure accurate machining and optimal utilization of CNC machines.

Effective operation of CNC machines demands a deep understanding of programming languages such as G-code and M-code. Operators need to be proficient in reading and interpreting these codes to program the machine accordingly. They must also possess problem-solving skills to troubleshoot any issues that may arise during the machining process.

Furthermore, CNC machine operators need to possess a strong mechanical aptitude and attention to detail. They must be capable of setting up the machine, including installing the necessary tools, workpieces, and fixtures. This requires knowledge of machine components, tool selection, and proper measuring techniques.

Key Operator Requirements for CNC Machining

| Requirement | Description |

|---|---|

| Programming Knowledge | Proficient understanding of programming languages such as G-code and M-code |

| Technical Aptitude | Strong mechanical aptitude and technical skills to operate and set up CNC machines |

| Problem-Solving Skills | Ability to troubleshoot and resolve issues that may arise during the machining process |

| Attention to Detail | Paying close attention to ensure accurate setup and machining processes |

Hiring and training skilled CNC machine operators can add to the overall cost of using CNC machines for manufacturing processes. However, their expertise is crucial to achieving high-quality results and maximizing the capabilities of CNC machining.

Material Limitations of CNC Machines

CNC machining, while versatile, does have some limitations when it comes to the materials that can be used. Different CNC machines may have restrictions on the types and properties of materials they can effectively work with. Therefore, it is crucial to have a thorough discussion with the machine shop to understand their capabilities and ensure they can work with the desired material for a specific application.

Some common material limitations in CNC machining include:

- Soft or brittle materials: CNC machines may struggle when working with materials that are too soft or brittle, as they may deform or break during the machining process.

- Exotic or specialized materials: CNC machines may not be equipped to handle certain exotic or specialized materials that require unique machining techniques or tools.

- Heat-sensitive materials: CNC machining generates heat, which can be detrimental to heat-sensitive materials, causing warping, melting, or other undesirable effects.

By understanding the material limitations of CNC machines, individuals can make informed decisions about the feasibility of using CNC machining for their specific material requirements. Consulting with an experienced machine shop can provide valuable insights into alternative manufacturing methods or potential workarounds for material limitations.

Table: Material Limitations in CNC Machining

| Material Type | Limitations |

|---|---|

| Soft or brittle materials | May deform or break during machining process |

| Exotic or specialized materials | CNC machines may not have the necessary capabilities or tools |

| Heat-sensitive materials | Heat generated during machining can cause warping or melting |

Awareness of the material limitations in CNC machining is essential to ensure successful and cost-effective production. By leveraging the expertise of machine shops and exploring alternative manufacturing methods, individuals can overcome these limitations and achieve desired outcomes for their projects.

Challenges of CNC Machining for Small-Scale Production

While CNC machining offers numerous advantages for large-scale productions and high-volume orders, it may present challenges for small-scale productions or small-batch orders. The complexity and time required for setup and programming can make CNC machining more intricate and time-consuming for smaller projects.

In small-scale productions, the initial investment in CNC machines and the associated programming and training costs can pose a financial burden. Additionally, the cost per unit may be higher for smaller production runs due to the fixed costs associated with CNC machining.

Moreover, the limited quantity of the production run may not fully utilize the capabilities and efficiency of CNC machines, making it less cost-effective compared to alternative manufacturing methods. For small-batch orders, it may be more viable to explore options such as manual machining or 3D printing, which offer greater flexibility and cost savings.

Table: Comparison of CNC Machining and Alternative Methods for Small-Scale Productions

| Factors | CNC Machining | Alternative Methods |

|---|---|---|

| Setup and Programming Time | Higher due to complexity | Lower for simpler processes |

| Costs | Higher initial investment and fixed costs | Lower initial investment and variable costs |

| Flexibility | Less flexible for quick design changes | More adaptable to design iterations |

| Production Efficiency | Higher for larger production runs | Comparable for smaller production runs |

Considering these challenges, it is crucial for small-scale manufacturers to carefully evaluate the specific requirements of their projects and weigh the benefits and drawbacks of CNC machining against alternative methods. By doing so, they can make the most appropriate decision to achieve their production goals effectively and economically.

Design Limitations of CNC Machines

CNC machines offer versatility in terms of shape, size, and texture, but they do have certain design limitations that should be considered. While CNC machining is capable of producing complex and intricate designs, there are some features that may be challenging to achieve with this manufacturing method. Designs that require intricate details or unconventional shapes may pose difficulties for CNC machines, limiting the design options available.

When utilizing CNC machining, it’s important to carefully consider the design requirements of your project. Discussing your design goals and limitations with the machine shop can help ensure that your desired design is feasible and achievable. By understanding the design limitations of CNC machines, you can make informed decisions about the best manufacturing method for your specific project.

While some design features may be restricted with CNC machining, it’s important to remember that there are alternative manufacturing methods available. Exploring other options, such as 3D printing or traditional machining, may offer different design capabilities and possibilities. Assessing your design needs and considering the available manufacturing methods can help you choose the most suitable approach for your project.

Overall, while CNC machining provides a wide range of design possibilities, it does have inherent limitations. Understanding these limitations and exploring alternative manufacturing methods can help you make informed decisions about the best approach for your project, ensuring that your design vision is realized effectively and efficiently.

Conclusion

CNC machining, despite its numerous advantages, has several drawbacks that potential users should consider. The higher cost compared to other methods may be justified by the added accuracy and precision, but it’s important to carefully assess the total cost and weigh it against the benefits before choosing CNC machining for a project.

In addition, size limitations can pose a challenge when working with larger parts that do not fit within the machine’s dimensions. Maintenance requirements are another crucial aspect to factor in, as regular cleaning, checking coolant levels, and servicing are necessary to ensure optimal performance.

The need for skilled operators with programming knowledge is another drawback of CNC machining. Hiring and training skilled operators adds to the overall cost and should be taken into consideration. Moreover, there may be limitations on the materials that can be used, so it’s essential to discuss material selection with the machine shop.

CNC machining may not be efficient or cost-effective for small-scale productions or projects with complex designs. Alternative manufacturing methods may be more viable in such cases. By carefully weighing the benefits against these drawbacks, individuals can make informed decisions about whether CNC machining is the right manufacturing method for their specific projects.

FAQ

What are the disadvantages of CNC machining?

Some disadvantages of CNC machining include higher cost compared to other methods, size limitations of CNC machines, high maintenance requirements, need for skilled operators and programming knowledge, limited material options, complexity for small-scale productions, and limited design flexibility.

Why is CNC machining more expensive?

CNC machines can be more expensive compared to other manufacturing methods due to the added accuracy and precision they offer. The cost of CNC machining should be weighed against the benefits before choosing it for a project.

What are the size limitations of CNC machines?

Some CNC machines have restrictions on the size of the workpiece that can be machined. This can be a challenge when working with larger parts that are not compatible with the machine’s dimensions. It’s important to consider the size requirements of a project before opting for CNC machining.

How much maintenance do CNC machines require?

CNC machines require regular maintenance to keep them running optimally. Regular cleaning, checking coolant levels, and servicing the machine are necessary to ensure smooth and uninterrupted operations. It’s important to factor in the maintenance requirements and associated costs when considering CNC machining.

Why do CNC machines require skilled operators?

CNC machines require operators who can accurately program and set up the machine for the desired operation. Skilled operators are essential to fully utilize the potential of CNC machining. Hiring and training skilled operators adds to the overall cost of utilizing CNC machines.

Are there limitations to the materials that can be used in CNC machining?

While CNC machines can work with various materials, the breadth of choices may be limited depending on the machine shop. It’s essential to discuss material selection with the machine shop and ensure they can work with the desired material for a specific application.

Is CNC machining suitable for small-scale productions?

CNC machining is well-suited for large-scale productions and high-volume orders. However, it may not be as efficient or cost-effective for small-scale productions or small-batch orders. The setup and programming time required for CNC machines can make it more complex and time-consuming for smaller projects. Exploring alternative manufacturing methods may be more viable for such cases.

What design limitations does CNC machining have?

While CNC machines offer versatility in terms of shape, size, and texture, they still have some design limitations. The complexity of certain designs may not be easily achievable with CNC machining. Design features that require intricate details or unconventional shapes may pose challenges for CNC machines. It’s important to consider the design requirements and limitations when deciding on CNC machining.