The use of a CNC machine control unit (MCU) offers a number of advantages over manual machining. The most obvious benefit is the increased accuracy and repeatability of the machining process. With a CNC machine, the operator can program the exact movements of the cutting tool, ensuring that the same part is produced each time. This eliminates the need for manual adjustments and reduces the risk of human error.

Another benefit of CNC machine control units is the increased speed of production. By programming the exact movements of the cutting tool, the machine can move faster than a human operator, resulting in a faster production rate. This can be especially beneficial in high-volume production runs.

CNC machines also offer increased safety for the operator. By programming the exact movements of the cutting tool, the operator can be sure that the machine will not move in an unexpected direction, reducing the risk of injury. Additionally, CNC machines can be programmed to stop automatically if an unexpected event occurs, such as a power failure or a tool breakage.

Finally, CNC machines offer increased flexibility. By programming the exact movements of the cutting tool, the operator can easily adjust the machine to produce different parts. This eliminates the need to purchase multiple machines for different parts, saving time and money. Additionally, CNC machines can be programmed to produce parts with complex shapes and intricate details, which would be difficult or impossible to produce with manual machining.

What are the benefits of CNC machines?

CNC (Computer Numerical Control) machines are automated machines that are used to produce parts and components with high precision and repeatability. They are used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC machines offer a number of advantages over traditional manual machining processes, including increased accuracy, improved productivity, and reduced labor costs.

One of the primary benefits of CNC machines is their accuracy. CNC machines are programmed with precise instructions, which allow them to produce parts and components with a high degree of accuracy. This accuracy is especially important in industries such as aerospace and medical, where even the slightest deviation from the desired specifications can have serious consequences. CNC machines also allow for the production of complex shapes and geometries that would be difficult or impossible to produce with manual machining processes.

CNC machines also offer improved productivity compared to manual machining processes. CNC machines can be programmed to produce multiple parts in a single cycle, allowing for faster production times.

How does the CNC technology benefit the industry?

The CNC (Computer Numerical Control) technology has revolutionized the manufacturing industry by providing a more efficient and cost-effective way to produce parts and components. CNC technology is used to control the movement of tools and machines, allowing for precise and repeatable production of parts and components. This technology has allowed for the automation of many processes, resulting in increased productivity and reduced labor costs.

CNC technology also allows for greater accuracy and repeatability in the production of parts and components. This is due to the fact that the machines are programmed with exact instructions, which are then followed precisely. This eliminates the need for manual labor and reduces the chances of human error. Additionally, CNC machines can be programmed to produce parts with complex shapes and sizes, which would be difficult or impossible to achieve with manual labor.

CNC technology also allows for faster production times, as the machines can be programmed to run continuously without the need for manual intervention. This reduces the amount of time needed to produce a part or component, resulting in increased efficiency and cost savings.

What is the purpose of the machine control unit?

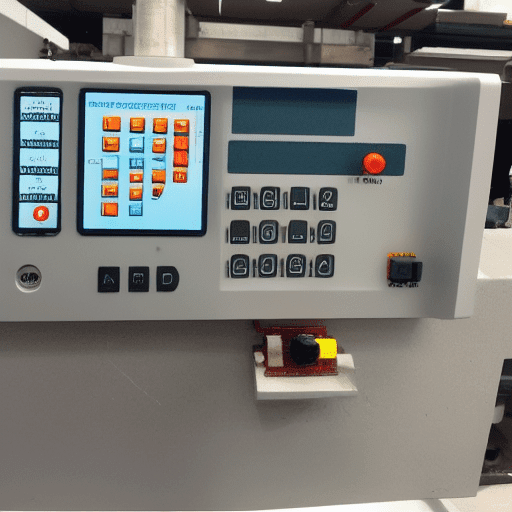

The machine control unit (MCU) is a type of computer system that is used to control and monitor the operation of a machine or process. It is typically used in industrial settings to control and monitor the operation of a machine or process, such as a manufacturing line, a robotic arm, or a power plant. The MCU is responsible for controlling the operation of the machine or process, as well as monitoring its performance and providing feedback to the operator.

The MCU is typically composed of a processor, memory, and input/output (I/O) devices. The processor is responsible for executing the instructions that control the operation of the machine or process. The memory stores the instructions and data that are used by the processor. The I/O devices are used to receive input from the operator or other external sources, and to provide output to the operator or other external destinations.

The MCU is responsible for controlling the operation of the machine or process by executing instructions that are stored in its memory. These instructions can be programmed by the operator or can be pre-programmed by the manufacturer.

What are the advantages of using the CNC lathe?

The CNC lathe is a computer-controlled machine tool that is used to shape metal and other materials into a variety of shapes and sizes. It is a highly precise and automated machine that can produce complex parts with a high degree of accuracy and repeatability. The advantages of using a CNC lathe include:

1. Increased Productivity: CNC lathes are able to produce parts quickly and accurately, which increases productivity and reduces costs. The machine can be programmed to produce multiple parts in a single setup, which eliminates the need for multiple setups and reduces the amount of time needed to produce a part.

2. Increased Accuracy: CNC lathes are able to produce parts with a high degree of accuracy and repeatability. This is due to the fact that the machine is programmed with precise instructions and is able to follow them precisely. This eliminates the need for manual adjustments and ensures that the parts produced are of the highest quality.

3. Reduced Labor Costs: CNC lathes are able to produce parts with minimal human intervention, which reduces labor costs.

Why CNC is important in control system?

Computer Numerical Control (CNC) is an important part of modern control systems because it allows for the automation of complex processes. CNC systems are used in a variety of industries, from aerospace to automotive, and are used to control the operation of machines such as lathes, mills, routers, and grinders. CNC systems are used to produce parts with high precision and accuracy, and can be programmed to produce parts with complex shapes and features.

CNC systems are advantageous because they are able to produce parts with a high degree of accuracy and repeatability. This is because CNC systems are able to precisely control the motion of the machine tool, as well as the speed and feed rate of the cutting tool. This allows for the production of parts with tight tolerances and high precision. Additionally, CNC systems are able to produce parts with complex shapes and features that would be difficult or impossible to produce with manual machining.

CNC systems are also advantageous because they are able to reduce the amount of time and labor required to produce parts.

What is the advantage and disadvantage of CNC machine?

The advantages of CNC machines are numerous. CNC machines are highly accurate, repeatable, and reliable. They can produce complex parts with a high degree of precision and repeatability. CNC machines are also very versatile and can be programmed to produce a wide variety of parts. They are also relatively easy to operate and maintain.

The main disadvantage of CNC machines is their cost. CNC machines are expensive to purchase and maintain, and require specialized training to operate. Additionally, CNC machines are limited in the types of materials they can work with, and require specialized tooling for each material. CNC machines also require a significant amount of setup time, which can be costly and time consuming. Finally, CNC machines are not suitable for all types of manufacturing, as some processes require manual labor or specialized equipment.

How many types of CNC controllers are there?

There are several different types of CNC controllers, each with its own unique features and capabilities. The most common types of CNC controllers are:

1. Standalone CNC Controllers: Standalone CNC controllers are the most basic type of CNC controller. They are typically used for simple operations such as drilling, milling, and turning. Standalone CNC controllers are usually limited to one or two axes of motion and are not capable of complex operations.

2. PC-Based CNC Controllers: PC-based CNC controllers are more advanced than standalone controllers and are capable of controlling multiple axes of motion. They are typically used for more complex operations such as 3D printing, engraving, and routing. PC-based CNC controllers are usually connected to a computer and use software to control the machine.

3. PLC-Based CNC Controllers: PLC-based CNC controllers are the most advanced type of CNC controller. They are typically used for industrial applications and are capable of controlling multiple axes of motion.

What is DPU in CNC?

DPU in CNC stands for Degrees Per Unit, and is a measure of the angular distance a CNC machine can move in one unit of time. It is used to measure the speed of a CNC machine, and is typically expressed in degrees per minute (DPM). DPU is important in CNC machining because it determines the speed at which a CNC machine can move, and therefore the speed at which a part can be machined. The higher the DPU, the faster the CNC machine can move, and the faster the part can be machined. DPU is also important in CNC machining because it determines the accuracy of the machined part. The higher the DPU, the more accurate the machined part will be. DPU is also important in CNC machining because it determines the amount of time it takes to complete a machining job. The higher the DPU, the faster the machining job can be completed.

How does a CNC controller work?

A CNC (Computer Numerical Control) controller is a device that is used to control the motion of a machine tool, such as a lathe, milling machine, router, or grinder. It is typically used in industrial settings to automate the production of parts and components. The CNC controller is the “brain” of the machine, and it is responsible for controlling the motion of the machine’s axes, as well as the speed and direction of the cutting tool.

The CNC controller is typically connected to the machine tool via a series of cables, and it is programmed with a set of instructions that tell the machine what to do. These instructions are typically written in a computer language such as G-code, which is a language specifically designed for CNC machines. The instructions tell the machine what type of motion to perform, how fast to move, and how much material to remove.

The CNC controller is also responsible for monitoring the machine’s performance and making sure that it is operating within the specified parameters.

Which do CNC machines use to control tool motion?

CNC (Computer Numerical Control) machines use computer programs to control the motion of tools. The computer program is typically written in a specific programming language, such as G-code, and is used to control the motion of the tool, as well as the speed and direction of the cut. The program is loaded into the CNC machine, which then interprets the instructions and moves the tool accordingly. The CNC machine can also be programmed to perform multiple operations in a single cycle, such as drilling, milling, and turning. This allows for complex parts to be created with a single setup.

What are the different types of CNC control units?

CNC (Computer Numerical Control) control units are the brains behind the operation of CNC machines. They are responsible for controlling the movement of the machine’s cutting tools and other components. There are several different types of CNC control units available, each with its own unique features and capabilities.

The most common type of CNC control unit is the G-code controller. This type of controller is programmed using a series of G-codes, which are instructions that tell the machine what to do. G-code controllers are typically used for simple operations such as drilling, milling, and turning.

Another type of CNC control unit is the conversational controller. This type of controller is programmed using a conversational language, which is a simplified version of G-code. Conversational controllers are typically used for more complex operations such as 3D printing and engraving.

How many controls are in a CNC machine?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses a computer program to control the movements of the machine. The number of controls in a CNC machine depends on the type of machine and the complexity of the operations it is designed to perform. Generally, CNC machines have three main components: the controller, the drive system, and the machine tool. The controller is the computer that runs the CNC program and controls the machine’s movements. The drive system is the mechanism that moves the machine tool, such as a motor, belt, or gear system. The machine tool is the actual tool that performs the cutting or machining operations.

In addition to these three main components, CNC machines may also have additional controls, such as a spindle speed control, a feed rate control, a coolant control, and a tool changer. The number of controls in a CNC machine can vary greatly depending on the type of machine and the complexity of the operations it is designed to perform.

What is the control system of CNC machine Mcq?

A CNC machine MCQ (Machine Control Query) is a type of control system used to control the operation of a CNC machine. It is a computer-based system that is used to control the operation of a CNC machine, such as a milling machine, lathe, router, or other type of CNC machine. The MCQ system is used to control the operation of the CNC machine by providing instructions to the machine, such as the type of tool to use, the speed and feed rate, and the cutting parameters. The MCQ system also provides feedback to the operator, such as the current position of the tool, the current speed and feed rate, and the current cutting parameters.

The MCQ system is typically composed of a computer, a controller, and a set of sensors. The computer is used to provide the instructions to the controller, which then sends the instructions to the CNC machine.